The IAM-AWP is equipped with a variety of state-of-the-art laser sources for various laser material processing applications. UV laser sources are applied as well as fiber lasers, solid state lasers, CO2 lasers and ultrashort pulse lasers. For analysis of the processing results a wide range of characterization techniques are used. In addition to standard metallographic methods and materials characterization procedures, scanning electron microscopy, surface profilometry, X-ray diffraction, electrochemical analysis and contact angle measurement are available.

Laserstrahlanlagen

|

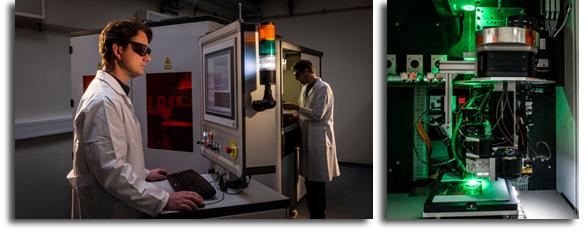

- 3x Ultrashort pulse laser (UV, green, NIR, 280fs-10ps, 20 W, 300 W) with roll to roll processing. - UV-FK-laser for laser printing (LIFT, Laser-induced Forward Transfer). - 4x Excimer-Laser (193 nm, 248nm, 10-20 W). - Yb:YAG fibre laser (NIR, 5ns-200 ns, 20 W). - 2x High power diode laser (940 nm, 50 W; 808 nm, 100W). - CO2 laser sources (40W).

|

Selected laser systems |

|

Analysemethoden

|

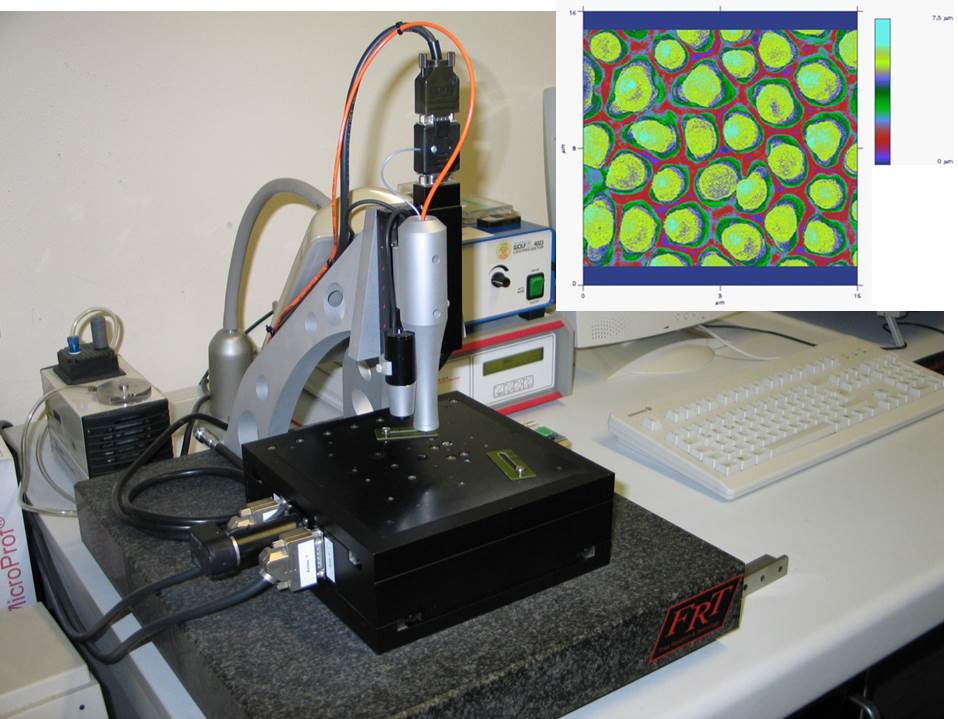

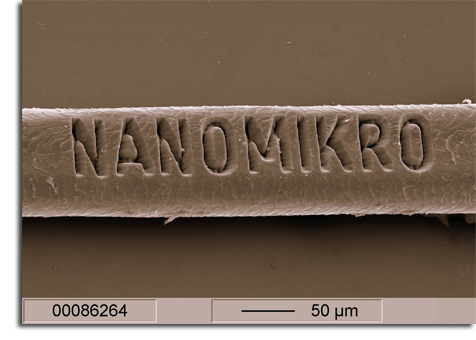

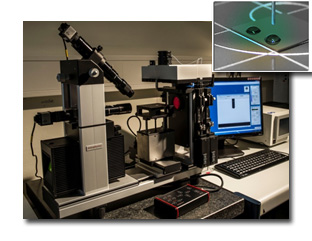

- Surface profilometry and roughnes measuring. - High resolution scanning electron microscopy and EDX (Philips XL30S; Phenom XL). - Metallography and sample preparation (e.g. Glovebox MBraun Labmaster dp). - Electrochemical characterization (3x battery cycler Arbin BT 2000). - Dynamic and static contact angle measurement (Dataphysics OCA 20). - Laser induced breakdown spectrocopy for spatially resolved qualitative and quantitative elemental analysis (LIBS, Secopta GmbH). - Nanoindenter (0,1-500mN, TTX-NHT3, Anton Paar GmbH). |

Surface characterisation via white light profilometry

Laser structured human hair |

Contact angle measurement on laser structures surfaces

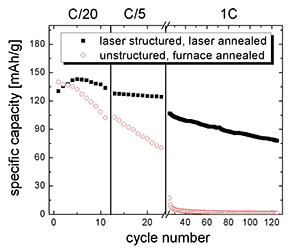

Specific discharge capacity as function of cycle number for laser structured and unstructured LiCoO2 thin films |