The research group “functional coating” is engaged in the development of soft magnetic thin films and functional films for lithium-ion energy storage technology applied in micro technology, nano technology and power engineering. The films are produced by means of physical vapour deposition (PVD), and they are consequently characterised concerning their properties. As a production technique, reactive and non-reactive DC or r.f. magnetron sputtering is employed. Modern lithography and etching methods enable patterning of the films by means of chemical (RIE) or physical plasma etching with high accuracy. The characterisation concerning their microstructure is carried out by optical microscopy, scanning- and transmission electron microscopy, scanning force microscopy, XRD, XRR, as well as Raman spectroscopy. For chemical composition the electron probe micro analysis and HF-GDOS is used.

|

|

|

|

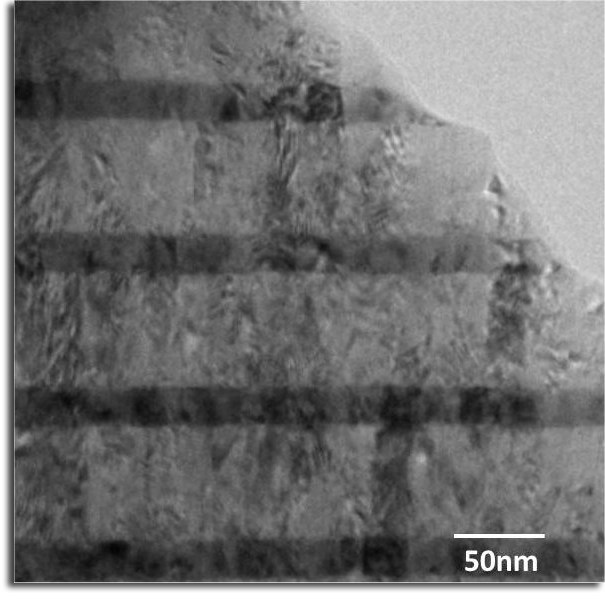

Bright field image (TEM) of a FeCo (20nm) / TiN (63nm) multilayer film. |

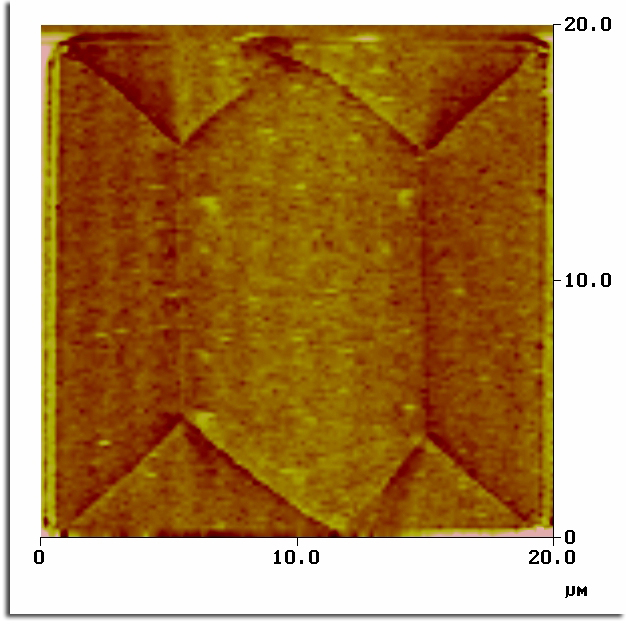

Dark field image (TEM) and diffraction diagram of an Fe-Co-Hf-N film | Domain image of a ferromagnetic micro structure (20 x 20 mm) measured by means of a Magnetic Force Microscope (MFM). |

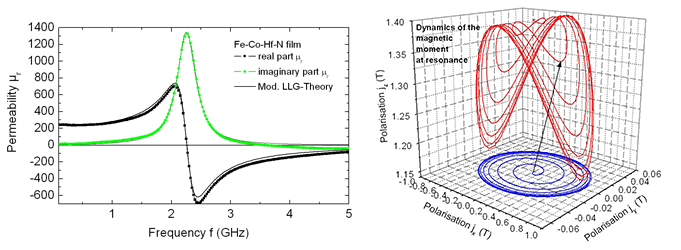

Soft magnetic thin films for high frequency applications up to the lower GHz range are deposited as single- and multi-layers with several hundreds of nanometers in thickness. The film material selection, among others, considers the CMOS compatibility. In this process, the high frequency properties are obtained (e.g., in-plane uniaxial anisotropy) by annealing the films between 400°C and 600 °C in a static magnetic field. The basic material is represented by Fe-Co-Re-NM composites with Re = refractory elements (Ta, Hf), NM = non metals like N, C, O. The activities cover basic- and application-oriented research of high frequency magnetism of single- and multi-layer film systems. Set-ups for measuring the static magnetisation (VSM, MOKE, MFM) and the high frequency behaviour (HF permeameter) are available. This research is accompanied by theoretic models and by micro magnetic modelling (e.g., OOMMF).

|

| Complex frequency-dependent permeability a Fe-Co-Hf-N film and computed precession trajectory of the magnetic moment |

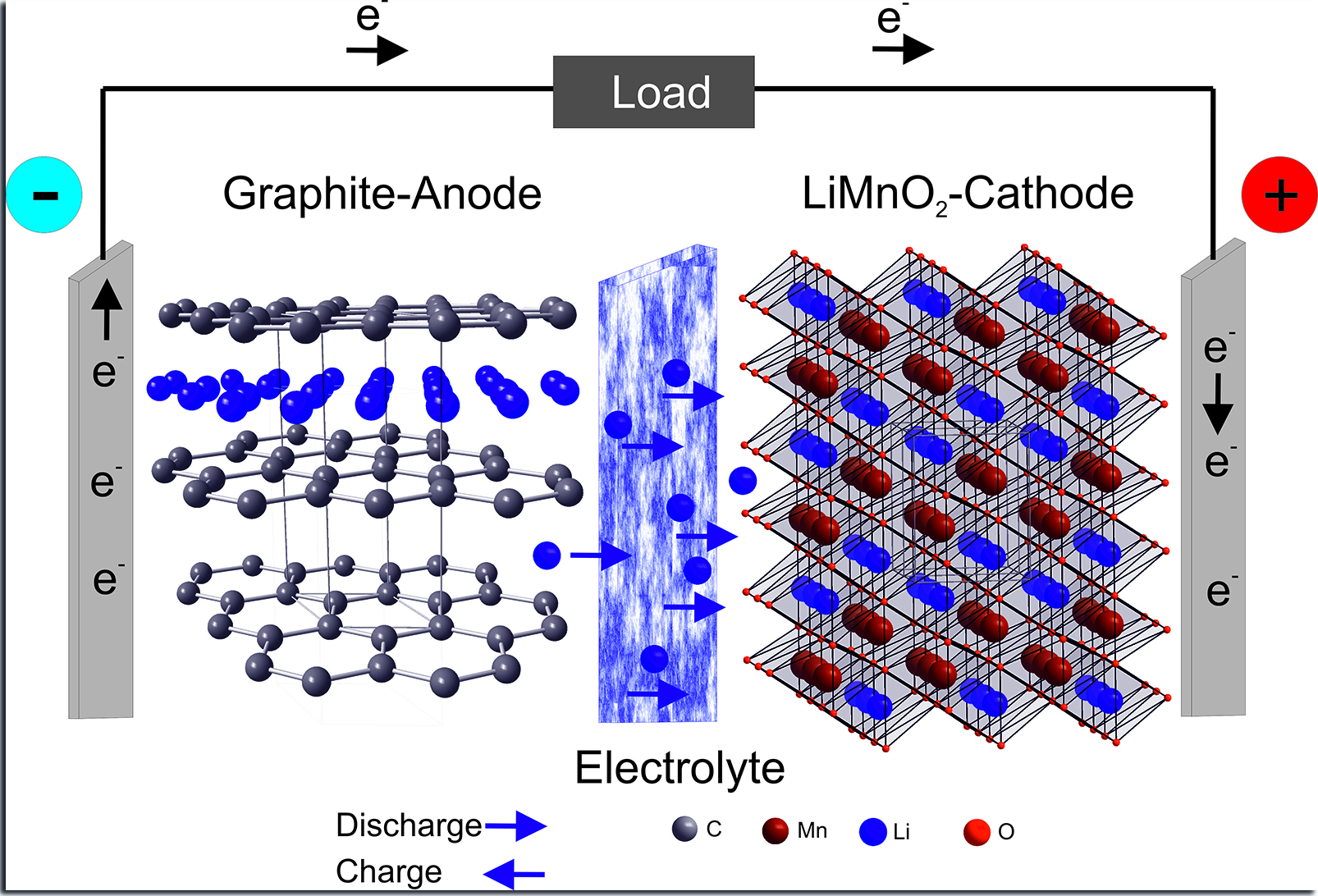

Functional films for lithium-ion storage. In this area, thin films are developed as cathode materials, anode materials and solid state electrolyte materials. Cathode materials are represented by lithium transition metal oxides like the LiCoO2, LiMnO2, LiNiO2 structures or by, e.g., the LiMn2O4. Thin film solid state electrolytes like amorphous Li-glasses and anode materials like conversion materials , e.g., SnO2 are also investigated. The aim of research induces the realisation of a complete thin film solid state battery. One focus of characterisation determines intrinsic features of pure materials without impurities of organic or carbon based additives for increasing the conductivity, as well as the identification of the electronic and ionic conductivity, the charge-discharge behaviour and the cycle stability in battery applications.

|

|

| Fracture surface of a LiCoO2 thin film | Schematic drawing of a lithium-ion battery |

|

|

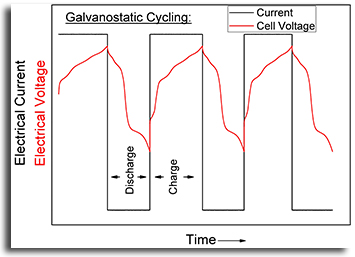

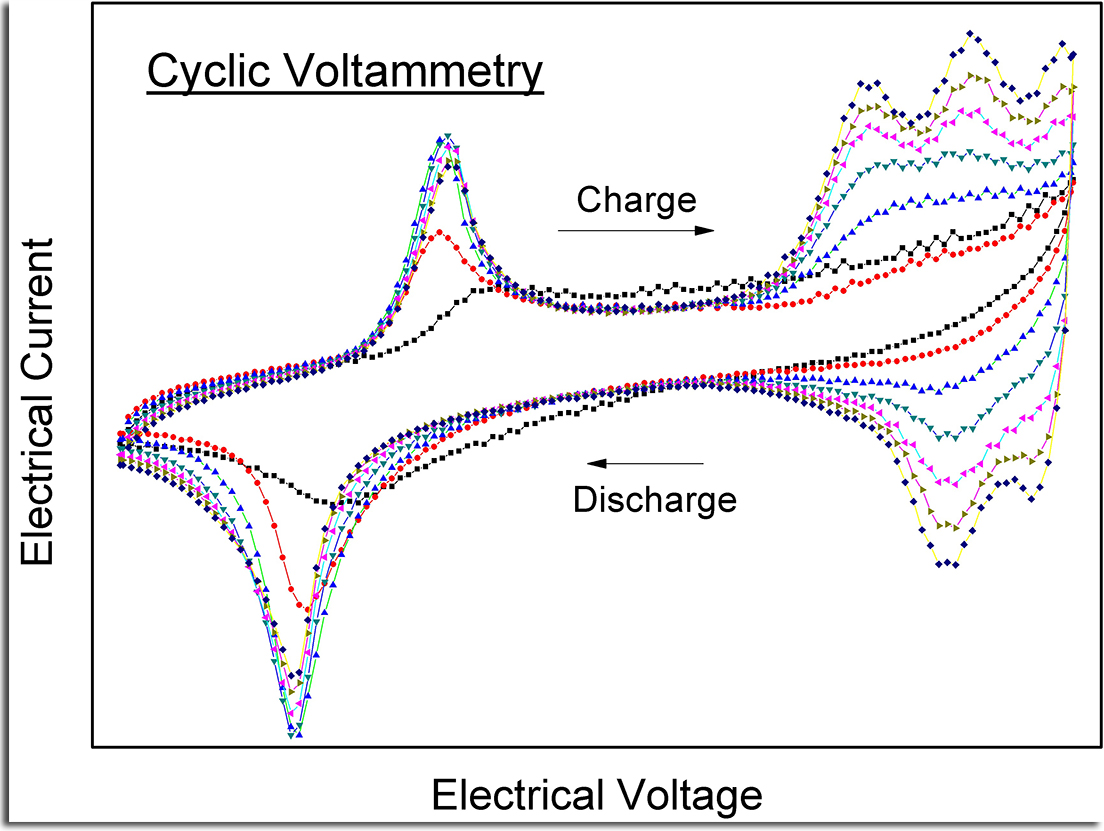

| Galvanostatic charge- and discharge curve | Cyclic voltammetry for the investigation of electrochemical behavior during the charge and discharge process |