|

Liquid metals are a group of coolants with increasing importance for high-temperature processes and power engineering. The favourable thermo-physical properties of liquid metals allow for high rates of heat removal in comparison to other coolants, e.g., water/steam. The compatibility of metallic construction materials with liquid metals may be strongly influenced by dissolved non-metals, especially oxygen. |

The Liquid Metal Technology Group at IAM-WPT investigates the compatibility of steels with liquid metals, concentrating on

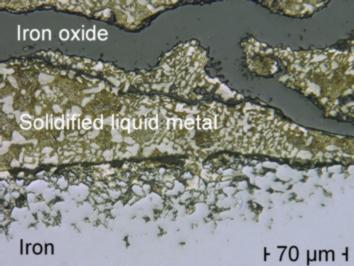

- The mechanisms and kinetics of steel corrosion in flowing oxygen-containing lead-bismuth eutectic (Pb45Bi)

- Development of corrosion models

- Creep-to-rupture in static oxygen-containing liquid lead

- Methods und instruments for controlling the content of dissolved oxygen in liquid lead alloys

|

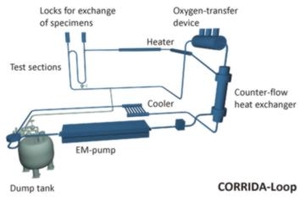

Liquid-metal loop CORRIDA (Corrosion in Dynamic Lead Alloys) CORRIDA is a forced-convection loop for exposing material specimens (steels) to flowing Pb45Bi at temperatures between 350 °C and 550 °C. Depending on the specimen dimensions, a flow velocity parallel to the specimen surface of 2 m/s can be achieved. The oxygen content of the lead alloy is controlled via mass-transfer between an oxygen-containing gas and the liquid metal (gas/liquid transfer). CORRIDA has been designed for long-term operation – currently, the longest exposure time of particular specimens is 20,000 h. The test-sections have a capacity for simultaneous exposure of 36 cylindrical specimens at a specimen length of 30 mm. |

|

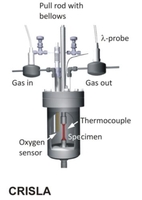

Creep-testing rig CRISLA (Creep-to-Rupture in Stagnant Lead Alloys) The creep-testing rig CRISLA consists of eight loading frames with integrated experimental capsules enclosing the investigated material in the testing environment. Five of these capsules are designed for creep-to-rupture experiments in static liquid lead or lead alloys, e.g., Pb45Bi, at up to 650 °C. The oxygen content of the liquid metal is controlled via oxygen-providing or absorbing gas mixtures. For this purpose, a modular measuring and control system was developed. Three capsules are used for reference experiments in static air. |

|

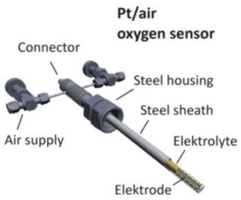

Oxygen sensors for use in liquid metals The sensors developed for measuring the oxygen concentration in liquid lead alloys work according to the principle of the lambda-probe, i.e., the difference in the oxygen chemical potential between the liquid metal and a reference electrode is transformed into an electric voltage. The solid electrolyte that separates the reference electrode from the liquid metal is yttria-stabilised zirconia. All the testing facilities operated by the group are equipped with such oxygen sensors. |

If you have any questions please contact Dr. Carsten Schroer.