Joining Technologies

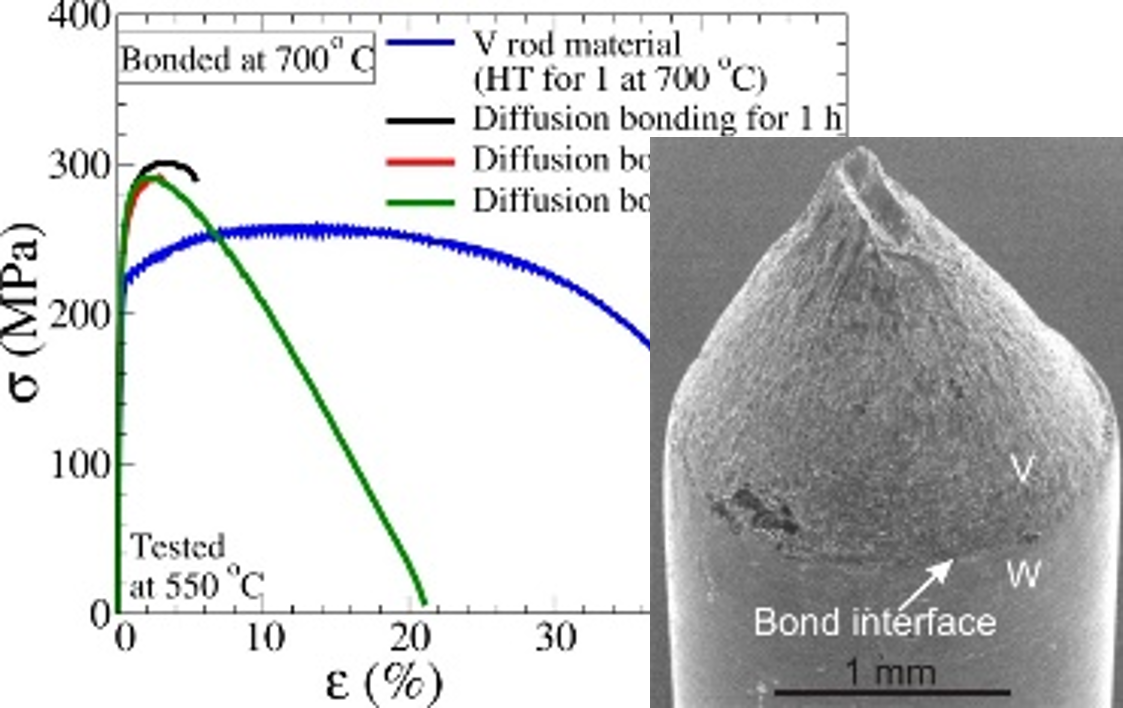

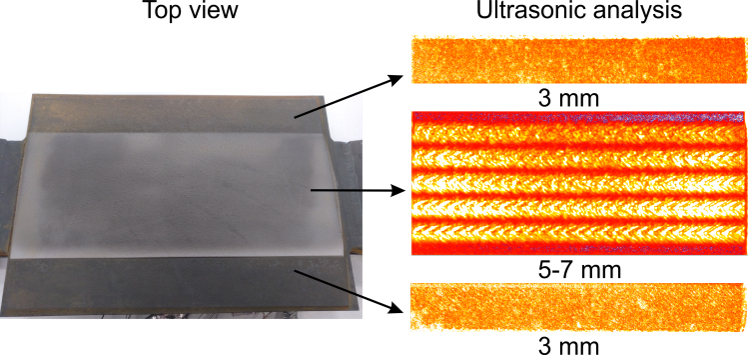

Our research activities aim at the development and optimization of joints by reducing defects and mechanical loads at the bonding interfaces and, hence, increasing strength and toughness of the joints. The main focus is set on methods which use joining temperatures considerably below the melting points of the involved base materials, e.g. brazing and solid state diffusion bonding. In addition, methods for bonding via functionally graded material are developed for joining dissimilar materials.

The development and optimization of joints are conducted on the base of modeling and simulation of the mechanical performance under processing as well as service conditions. In addition, extensive microstructural and mechanical characterizations as well as non-destructive testing are carried out, on the one hand to support the modeling and on the other hand to assess the bonding quality of the fabricated joints.

Current research projects

- Development and optimization of functionally graded steel/tungsten coatings for fusion first wall applications (A. Mishra, J. Aktaa)

- Characterization and modelling the material properties of functionally graded W/EUROFER coatings for First Wall components (C. Manoli, A. Mishra, J. Aktaa)