Equipment

The IAM-AWP has extensive equipment with state-of-the-art laser beam sources and analysis methods.

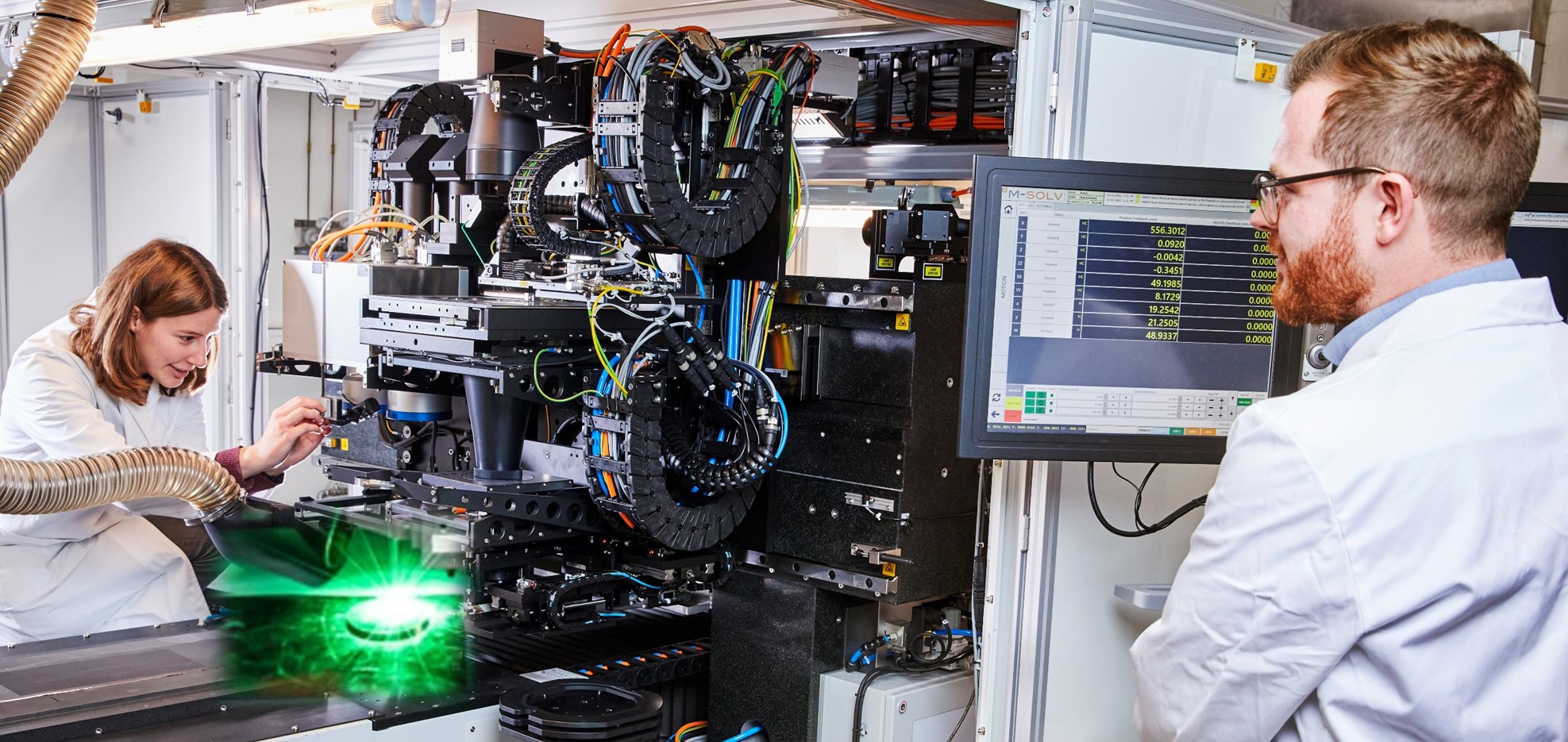

Laser beam systems

- Ultra-short pulse laser (NIR, 600fs, 300 W) with roll-to-roll and dual scanner processing

- Ultra-short pulse laser (NIR, 500W) with roll-to-roll and large-field scanner processing

- Ultra-short pulse laser for micro/nanostructuring (UV, green, NIR, 400fs-10ps, 35W)

- Ultra-short pulse laser for micro/nano structuring (NIR, 280fs, 20W)

- UV solid-state laser for microstructuring (scanning mask imaging) and for laser printing (laser-induced forward transfer)

- Excimer laser for microstructuring (193 nm, 248nm, 10-20 W)

- Yb:YAG fibre laser for structuring (NIR, 5ns-200 ns, 20W)

- High power diode laser for annealing and transmission welding (NIR, 100W)

- CO2 laser for microstructuring and cutting (40W)

Methods of analysis

- Surface profilometry and roughness tester

- Scanning electron microscopy and EDX

- Materialography and sample preparation

- Electrochemical characterisation

- Dynamic and static contact angle measurement

- Laser induced breakdown spectroscopy (LIBS) for spatially resolved qualitative and quantitative elemental analysis

- Nanoindenter (0.1-500mN)

Battery lab

- Slurry production (speed mixer, ball mill, dissolver)

- Rheometer

- Coating equipment (Lab-Coater, R2R)

- Dryers and ovens

- Calander

- Ultrasonic welding unit

- Button cell production (CR2032)

- Pouch cell production (up to 5Ah)