-

Materialographic preparation (cutting, grinding, polishing, etching) and microstructure characterization by optical and electron microscopy

-

Scanning electron microscopy

-

High-resolution transmission electron microscopy with modern analysis techniques (FEG, HAADF, EFTEM, EELS, EDS)

-

Scanning probe microscopy with scanning force, friction force and magnetic force microscopy

-

X-Ray diffraction

-

Surface and bulk analysis

-

Mechanical testing equipment, e.g. hardness measurement, nano- and microindentation methods, tensile micro and macro-scale bending tests

-

3D topography by white-light chromatic aberration

-

Laboratory for laser technology equipped with cutting-edge processing facilities and beam sources in the UV (excimer, Nd:YAG, diode lasers), VIS (Nd:YAG) and in the IR (diode laser, Nd:YAG, CO2) spectral ranges

-

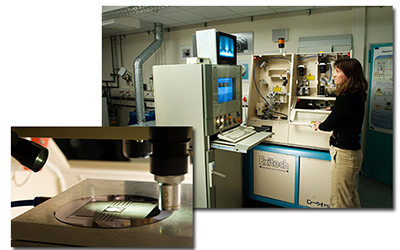

Thin-film laboratory with up-to-date coating facilities and thin-film equipment/technologies (magnetron sputtering, arc evaporation, plasma-assisted CVD)

-

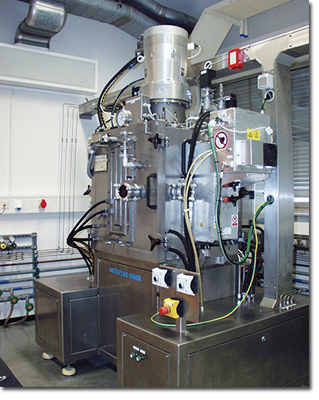

Instrumented creep facilities for test temperatures up to 1300 °C

-

Characterization facilities for material properties: thermophysical and thermodynamical, mechanical, electric, magnetic, dielectric as well as high-frequency properties

-

Facilities for physico-chemical studies: High-temperature reactions of metallic and ceramic materials, hydrogen absorption, diffusion and

desorption -

3 electromechanical universal testing machines with integrated furnace for tests in vacuum up to 1400 °C

-

1 Charpy machine for impact tests in normal atmosphere: -190 °C to 500 °C

-

1 Charpy machine for impact tests in vacuum up to 1100 °C

-

30 long-term creep facilities for tests in normal atmosphere up to 750 °C

-

20 long-term creep facilities for tests in vacuum up to 800 °C

-

1 long-term creep facility for tests in vacuum up to 1300 °C