Fusion Ceramics

|

Fabrication

|

|

|

Characterisation

|

|

|

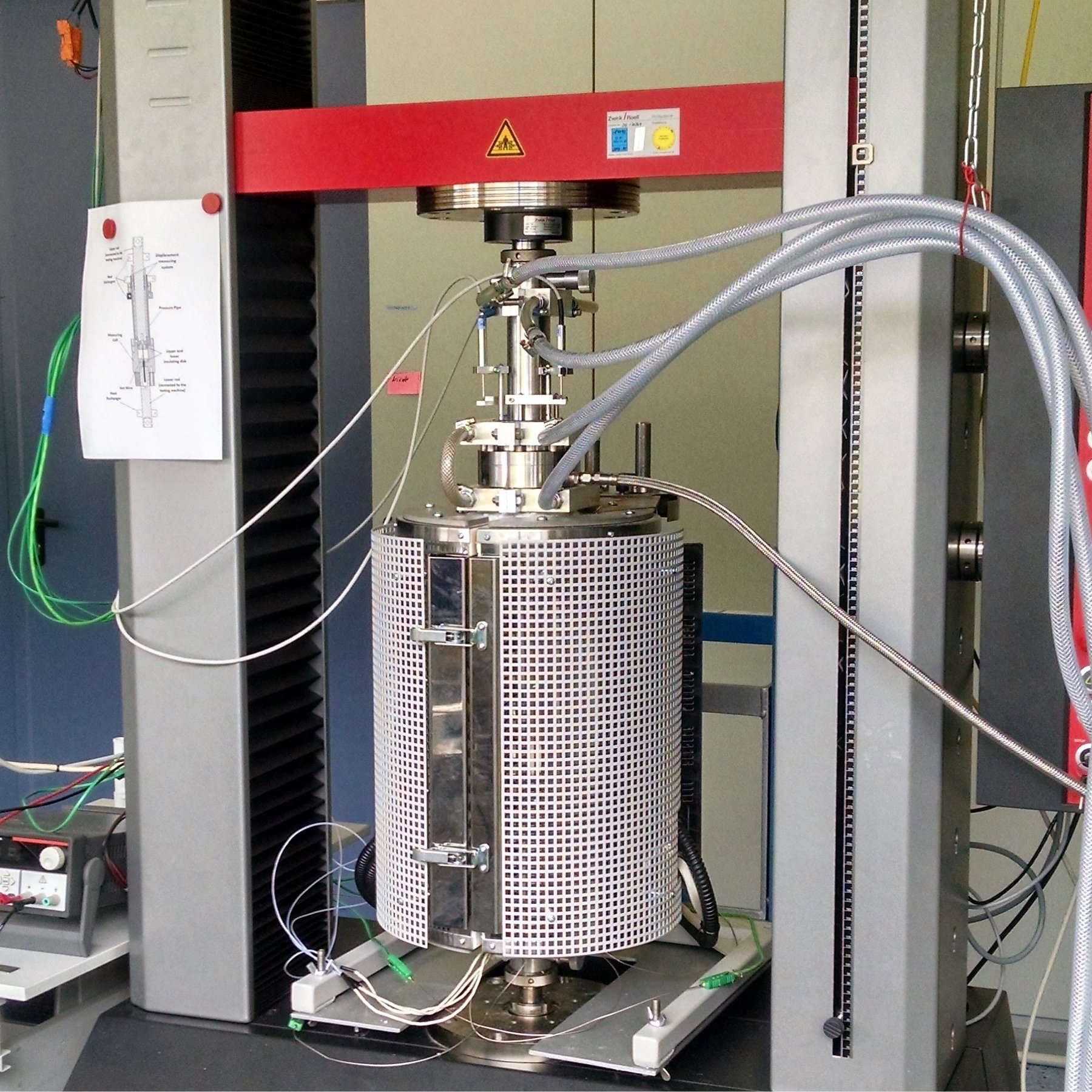

Qualification

|

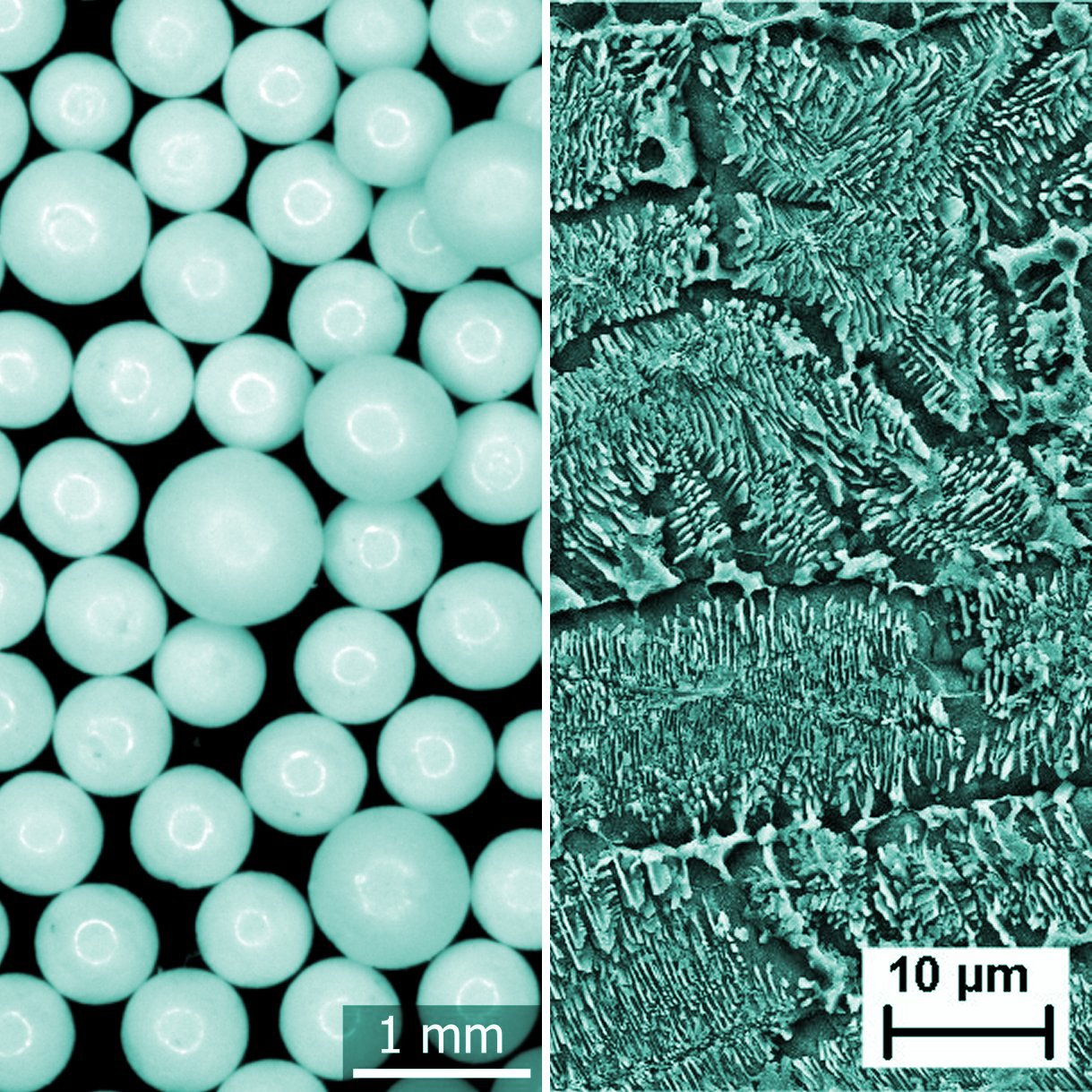

Lithium containing ceramics,e.g. lithium orthosilicate (Li4SiO4) and lithium metatitanate (Li2TiO3), are under development as a possible tritium source, a so-called tritium breeding material, for future nuclear fusion reactors. In the present design of the helium cooled solid breeder blanket, these ceramics will be inserted as pebble beds with pebble diameters ? 1 mm in the plasma surrounding blanket modules. The unstable isotope of hydrogen, tritium, is generated during the operation of the reactor by the transmutation of the lithium-6 isotope under neutron irradiation into helium and tritium. These ceramics are to be used in the European test blanket module, which will be tested in ITER in Cadarache, France.

The lithium orthosilicate based ceramic pebbles are produced by a melt process via droplet generation. In comparison to powder technological fabrication routes, this process offers particular advantages relating to an easy reprocessing as possible waste is reduced. At KIT the process technology and the material development and evaluation of mixed ceramics made of lithium orthosilicate and lithium metatitanate are advanced for the future application in fusion technology.

A detailed characterization of the pebbles is carried out before the material is evaluated in mostly European or internationally coordinated experiments. While the further development and evaluation of the material is pursued within the EUROfusion Work Programme or in Fusion for Energy (F4E) projects together with European partners, there is also a close collaboration with the international partners involved in ITER, especially with QST in Rokkasho, Japan.