The safety of light-water reactor (LWR) is since several years the principal topic of the NUSAFE program at Karlsruhe Institute of Technology (KIT). The Nuclear Safety Research Group is engaged in investigation of the accident relevant scenarios of LWR. Thereby, in the foreground of interests is the quantification of phenomena, which could be developed during design basis accidents (temperature less than 1200 °C) as well as during postulated severe accidents (temperature higher than 1200 °C)

Main questions in description of severe accidents are following:

- when and how does the reactor core lose its geometry as consequence of escalating temperature,

- at what time will relocate the solid as well as the liquid core material into the lower part of the reactor pressure vessel,

- how much hydrogen will be generated due to oxidation of core material by steam and in what kind depends the hydrogen production rate on the core damage development,

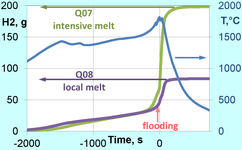

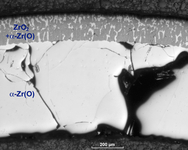

- in which way is it possible to cool a partially blocked core with water. In respect of timely termination of severe accident, the flooding of the overheated core with water is one of the most important measures. The strong exothermic chemical interaction between steam and cladding tubes (different Zr-alloys) during the flooding can cause the intensified temperature escalation accompanied with large hydrogen production.

|

Typical configuration of the QUENCH-bundle |

Following phenomena play a decisive role for the increased hydrogen production:

Further phenomena, connected with air ingress and debris bed formation, will be studied in framework of international projects LACOMECO, NUGENIA, ACTOF and FUMAC (IAEA).

|

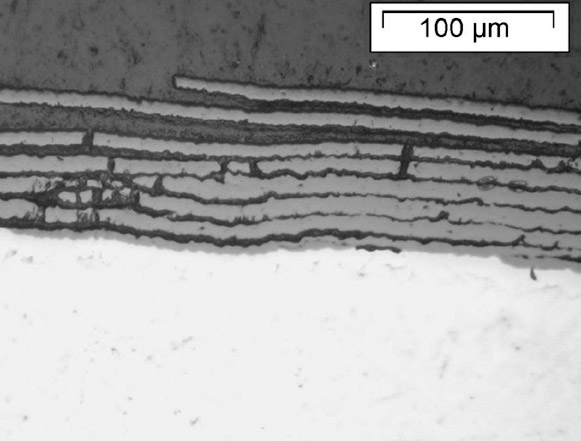

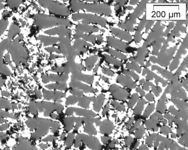

Due to different advantages the current trend in the nuclear industry is to increase fuel burn-up. At high burn-up, fuel rods fabricated from conventional Zry-4 often exhibit significant oxidation, hydriding, and oxide spallation. Thus, many fuel vendors have proposed the use of recently developed cladding alloys. Therefore, it is important to verify the safety margins for high burn-up fuel and fuel claddings with new alloys. The current LOCA (Loss-of-Coolant Accident) criteria constitute the conditions of cladding embrittlement due to oxygen uptake. Because of long cladding hydriding period for the high fuel burn-up, post-quench ductility is strongly influenced not only by oxidation but also hydrogen uptake. Due to so called secondary hydriding (during oxidation of inner cladding surface after burst) the hydrogen content can reach significant values in cladding regions around burst. The influence of this effect on the cladding embrittlement will be investigated in framework of recently started QUENCH-LOCA program. |

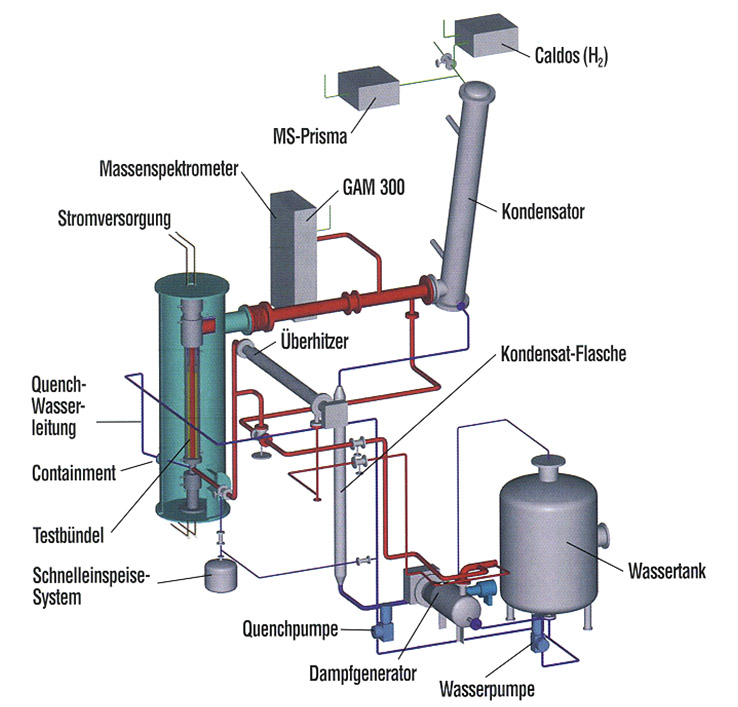

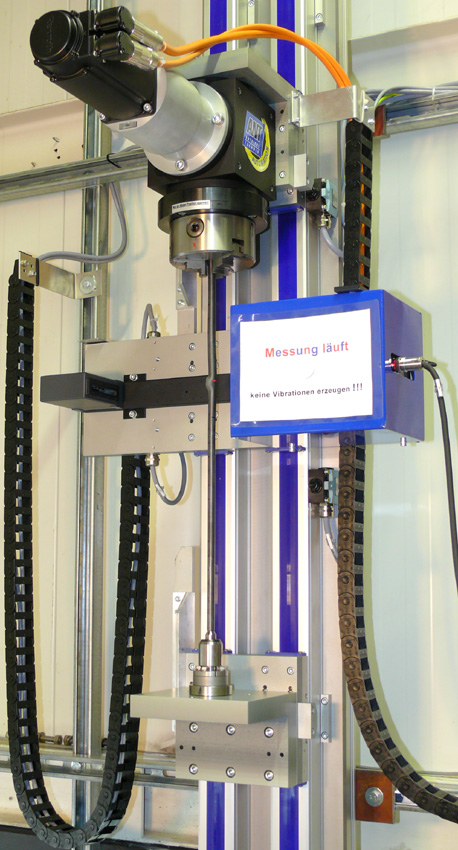

Following facilities are operated by the Nuclear Safety Research Group:

|

|

|

|

|

|

The group uses two computer codes for the pre- and posttest modelling:

- mechanistic code SFPR/SVECHA for single rod calculations,

- integral code ASTEC for bundle experiments.

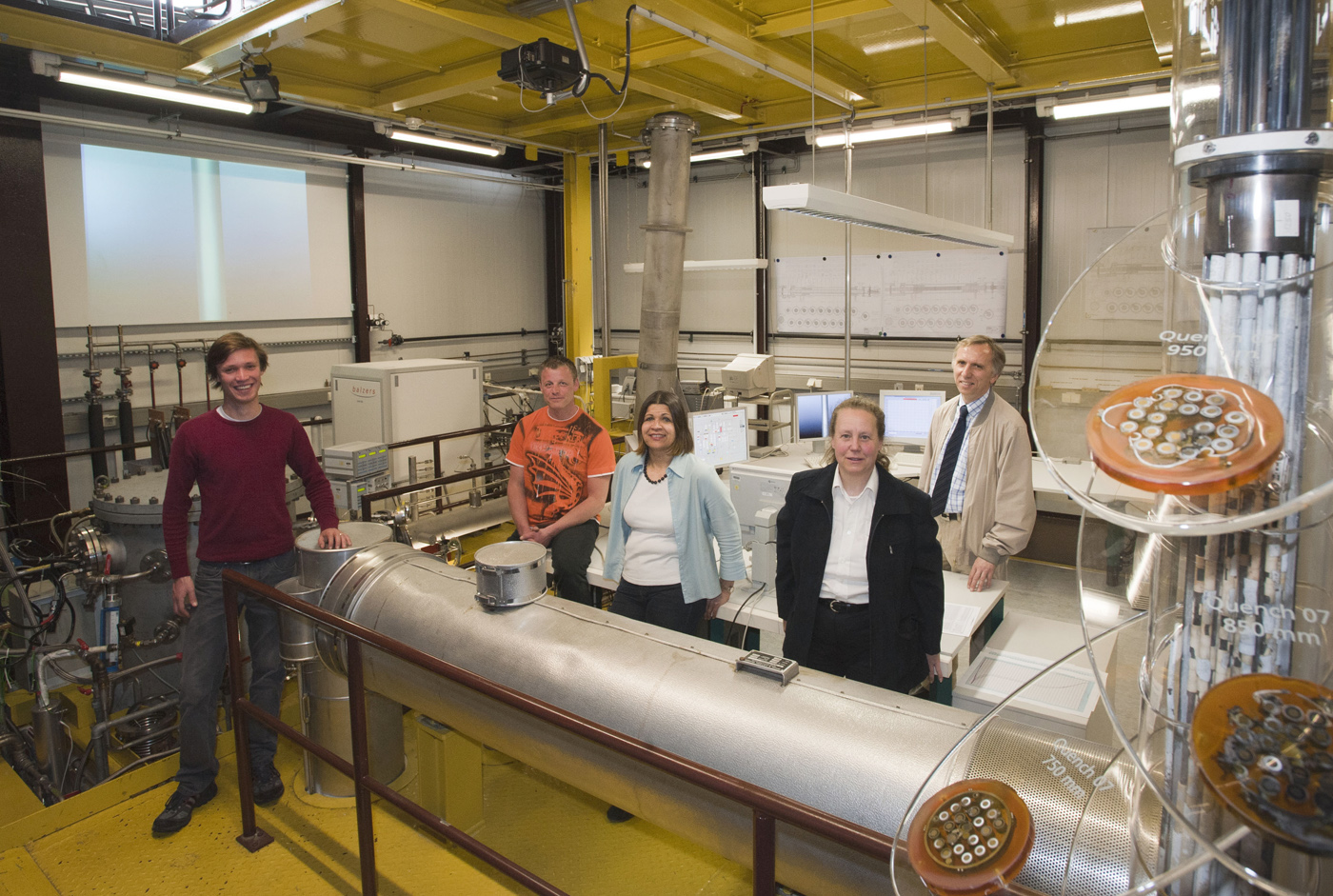

Group staff:

Jutta Laier, Jürgen Moch, Dr. Heinrich Muscher, DI Ursula Peters, Dr. Anton Pshenichnikov, DI Conrado Rössger, Dr. Juri Stuckert

For further questions to these topics please contact Dr. Juri Stuckert.