Research

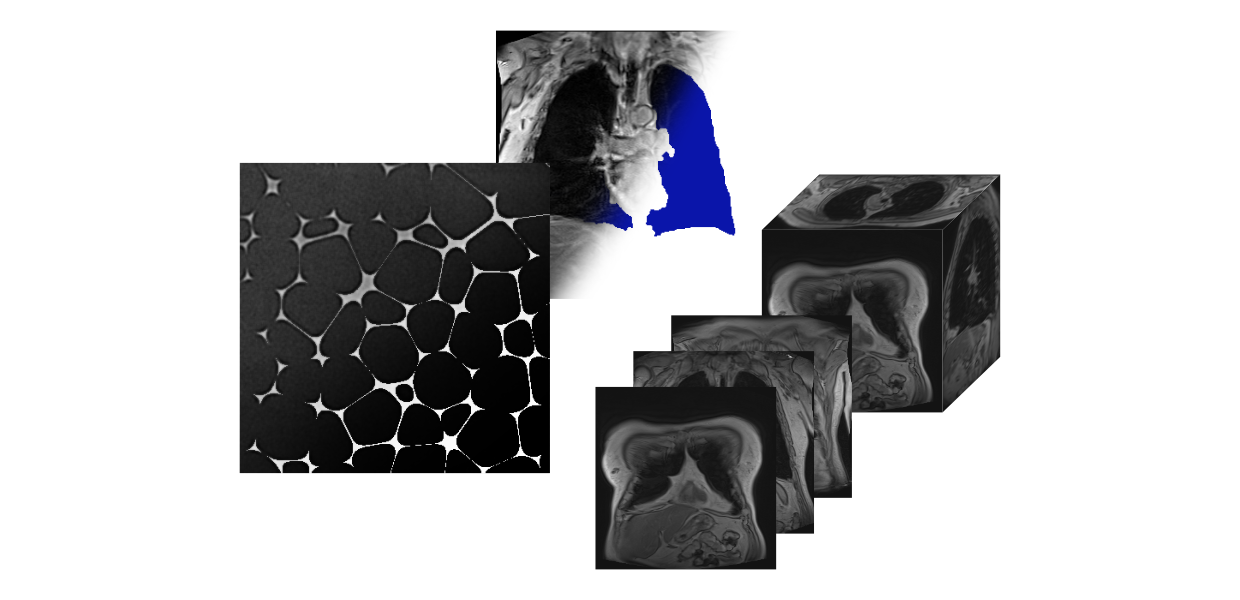

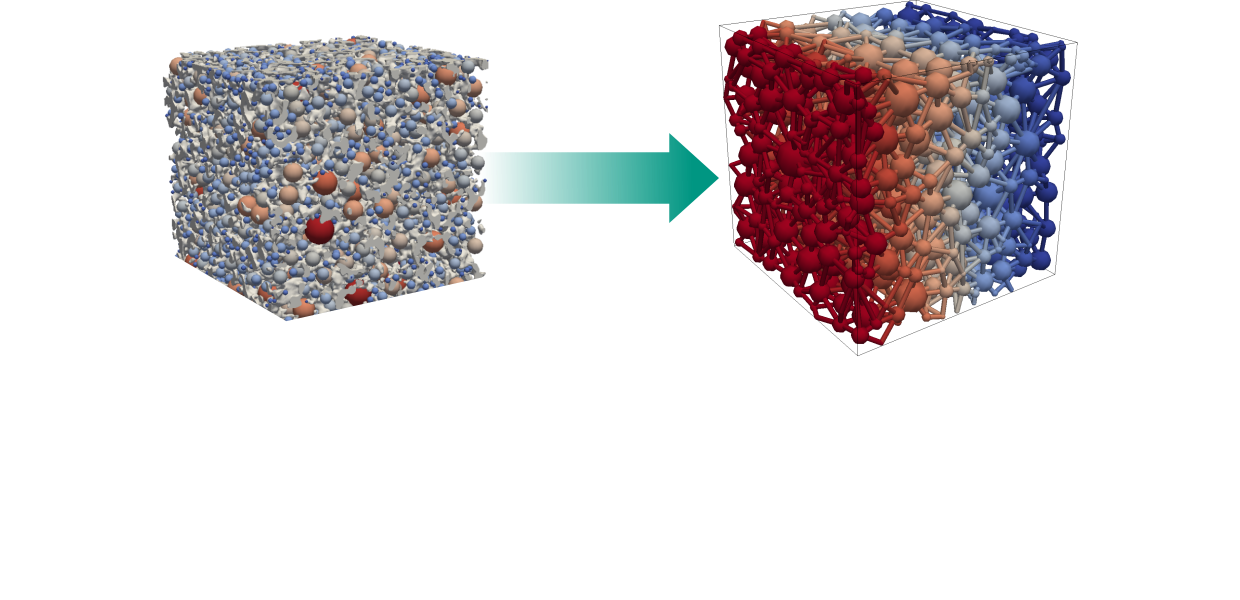

The research group “Microstructure – Data Science” focuses on the data-driven analysis and optimization of microstructures. To this end, methods for segmentation, characterization, and structure synthesis are developed, alongside data-driven analysis tools that make the interplay between microstructural features and macroscopic material behavior observable. In addition, computer vision techniques are specifically applied to medical imaging data. The developed methods are designed such that they can be transferred across domains and address both materials science and medical applications. For the creation of digital twins of microstructures, large-scale phase-field simulations are combined with computer vision methods that segment image data from various imaging modalities and reconstruct them into high-resolution 3D models. Building on these representations, generative algorithms and generative AI models are employed to synthesize microstructures with controllable properties, enabling realistic representations of porous systems such as membranes, grain structures, and geological packings. In collaboration with the “Research Data Management” group, workflows are developed for the reproducible and FAIR-compliant analysis of large datasets, ensuring that the described methods are automated, standardized, and reusable across different application contexts. The overarching aim of the research activities is the bridging of length scales through the identification of effective structure–property relationships and the development of data-driven predictive models that support accelerated and informed materials design.

Computer Vision

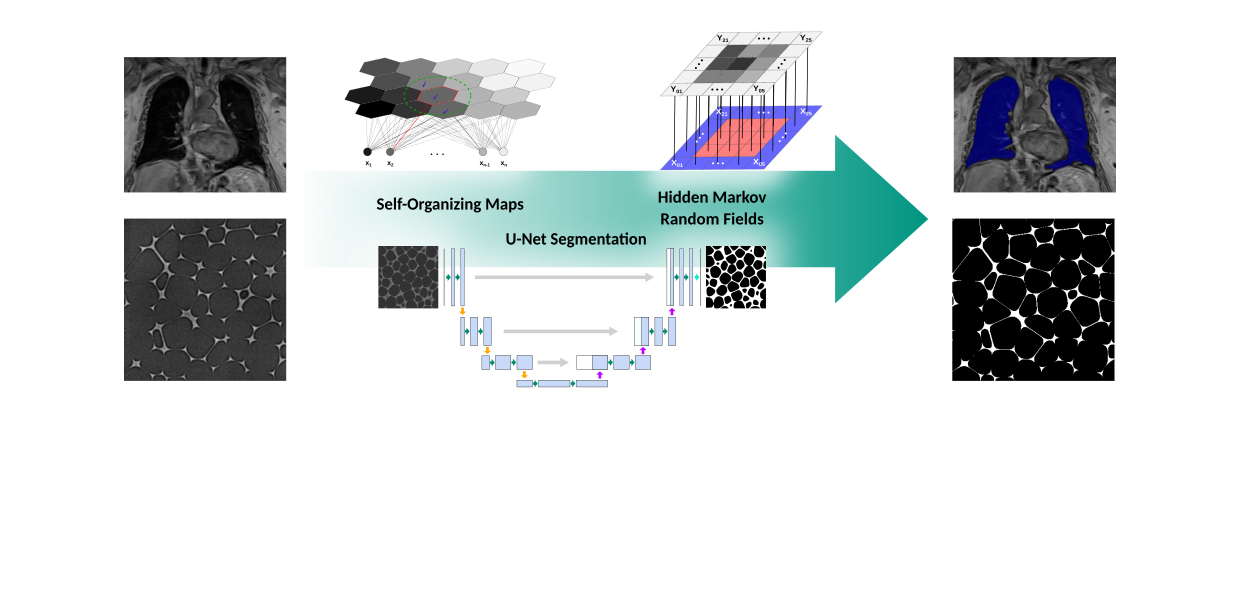

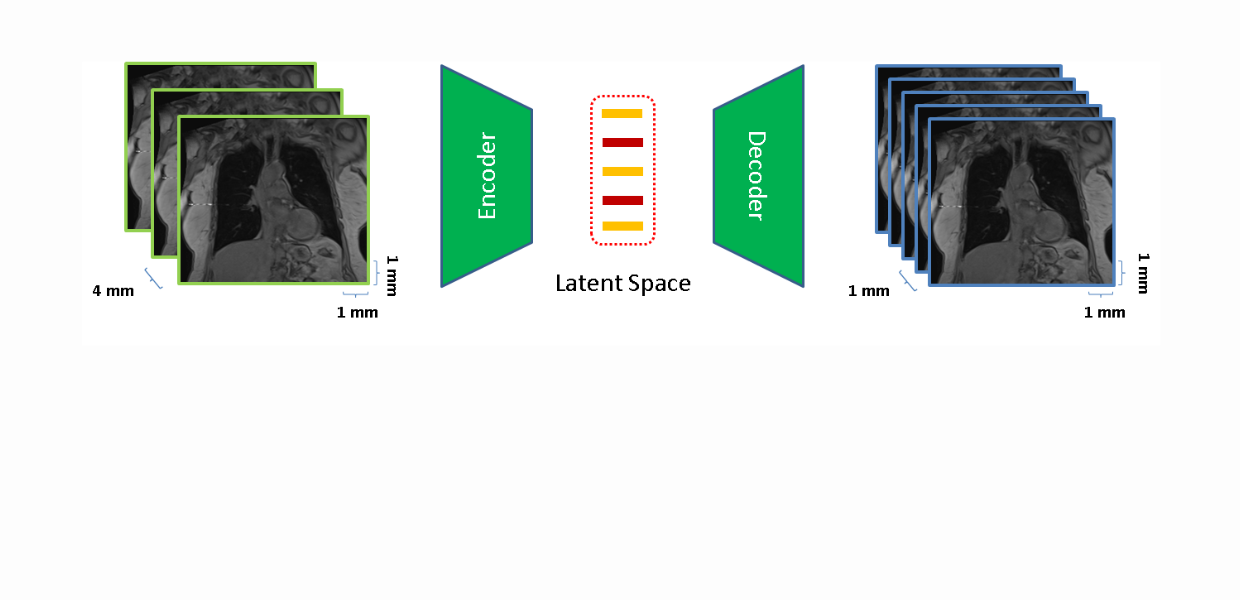

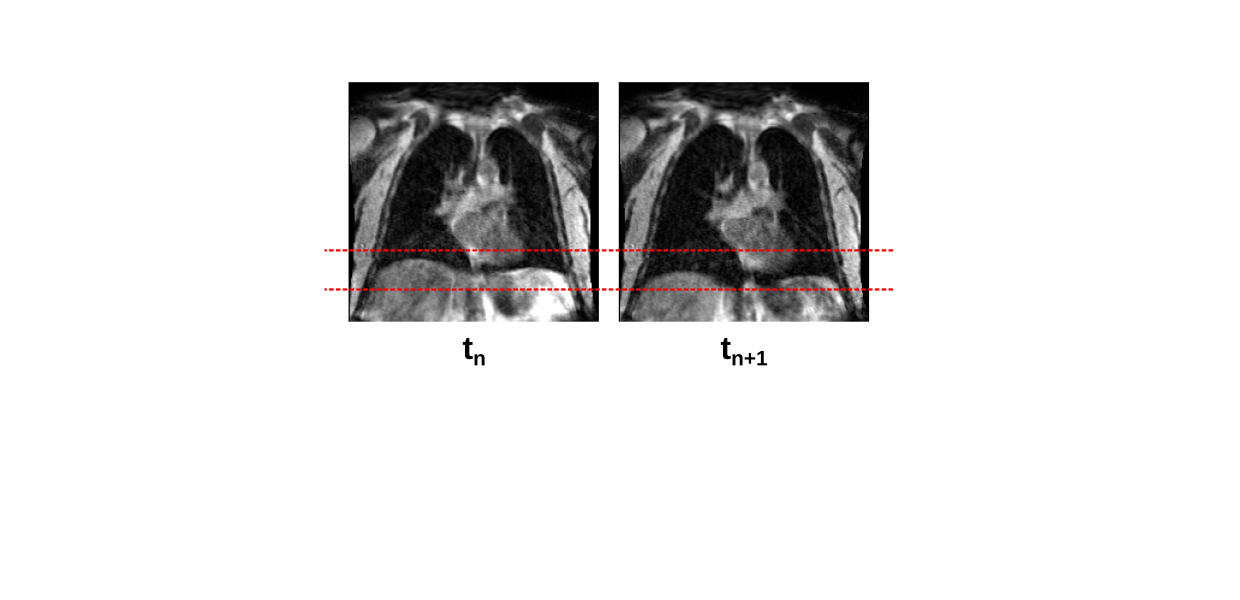

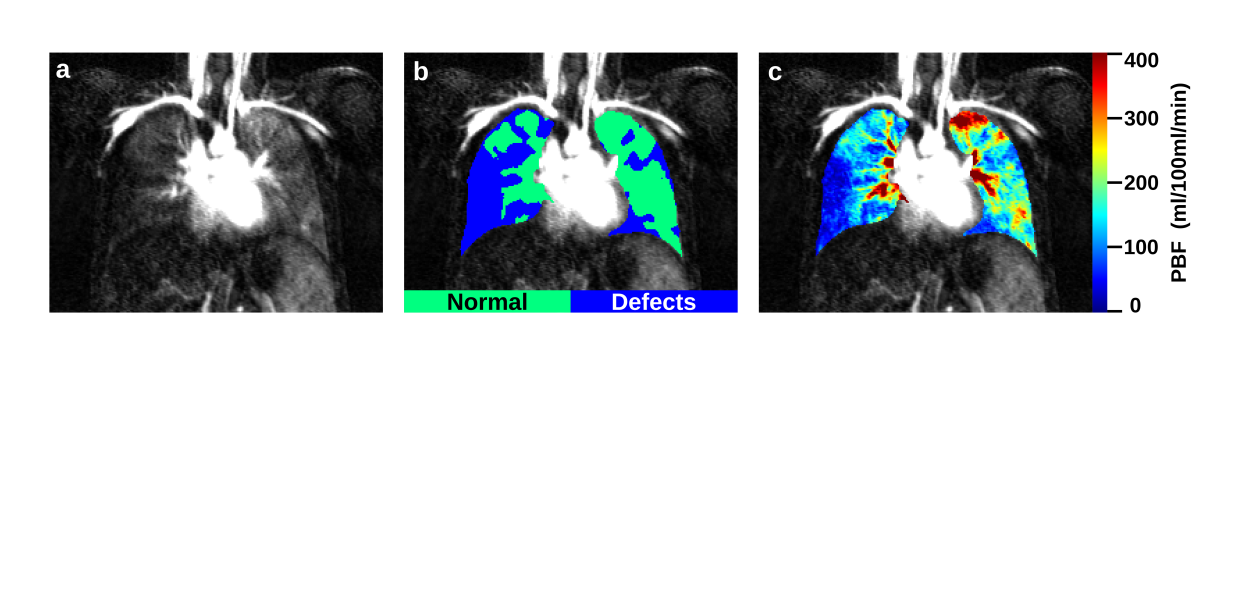

In the field of computer vision, versatile methods are developed for the automated analysis of complex image data from a wide range of modalities, including CT, MRI, and confocal microscopy. Core tasks include segmentation, reconstruction, registration, and super-resolution. By employing flexible model architectures, strategies for limited datasets, and the generation of synthetic training data, robust approaches are created that can be reliably transferred across different domains. In this way, both the creation of digital twins in materials science and the precise analysis of medical imaging data are supported.

Characterization

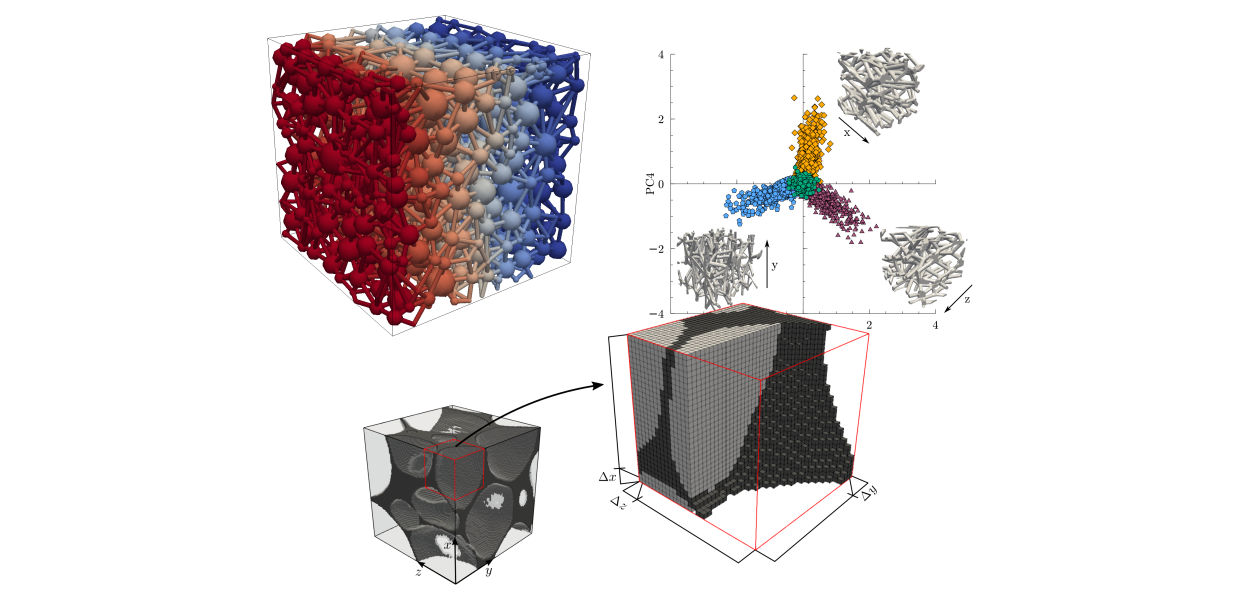

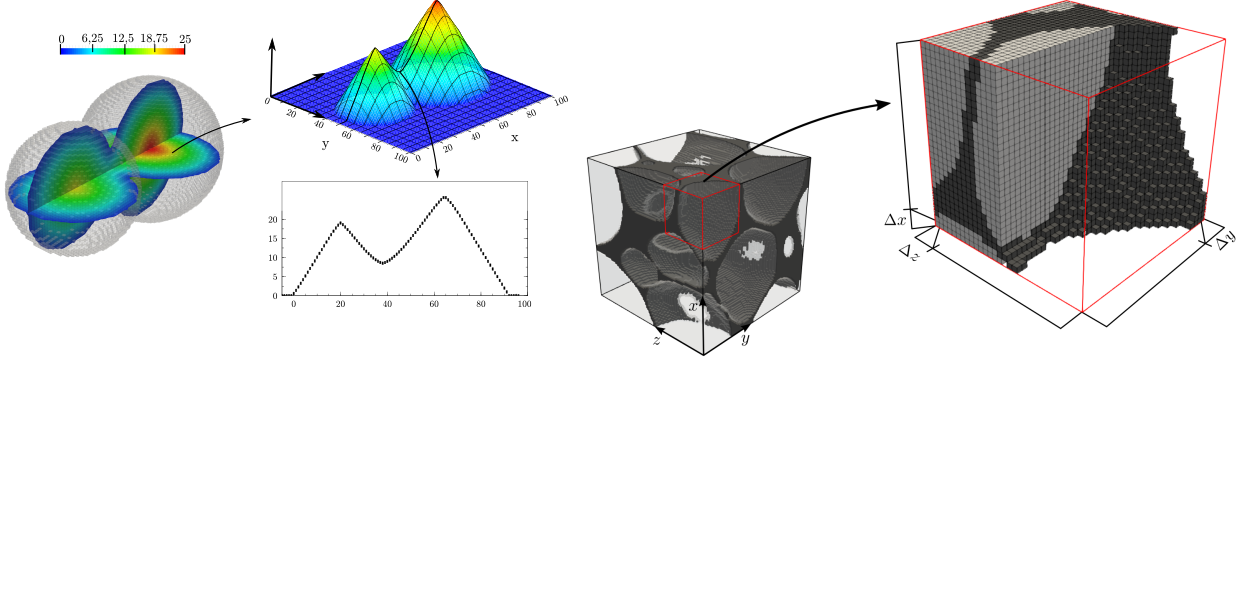

To characterize microstructures, methods are developed for the quantitative description of complex geometries and statistical features. Based on digital material twins, classical descriptors such as porosity, wall thickness, pore-size distributions, and tortuosity are determined, along with higher-dimensional features derived from data-driven approaches such as two-point correlation functions or principal component analysis. In addition, neural networks are employed to identify latent structural patterns. Beyond materials science applications, medical imaging data are also analyzed, for example segmented lungs for perfusion assessment.

Structure Synthesis

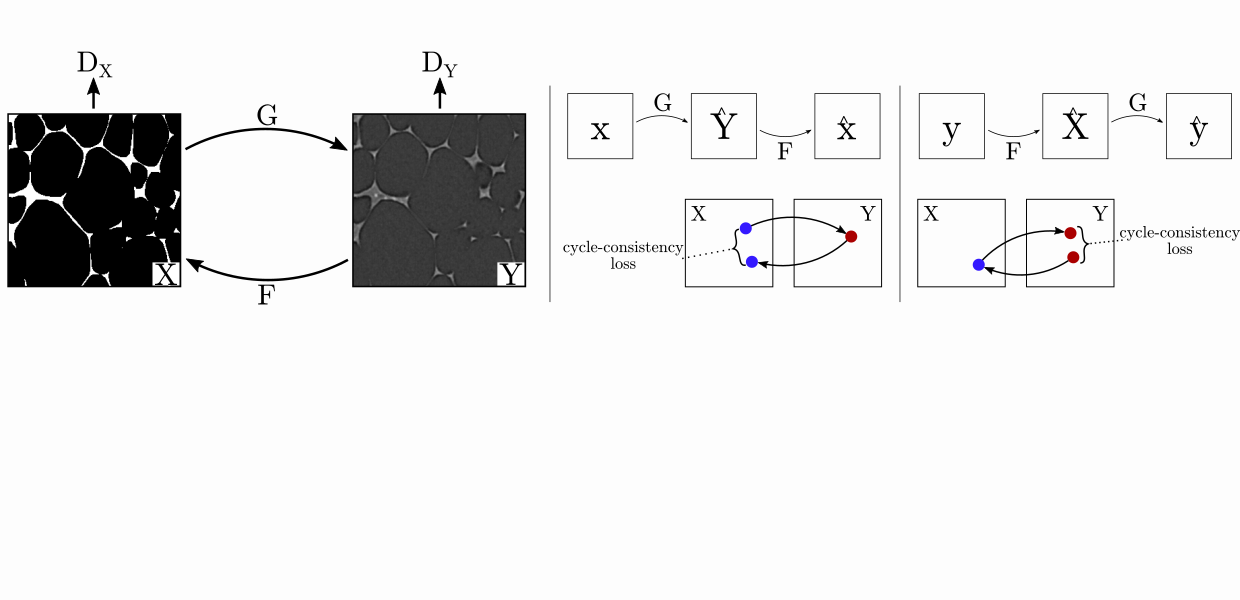

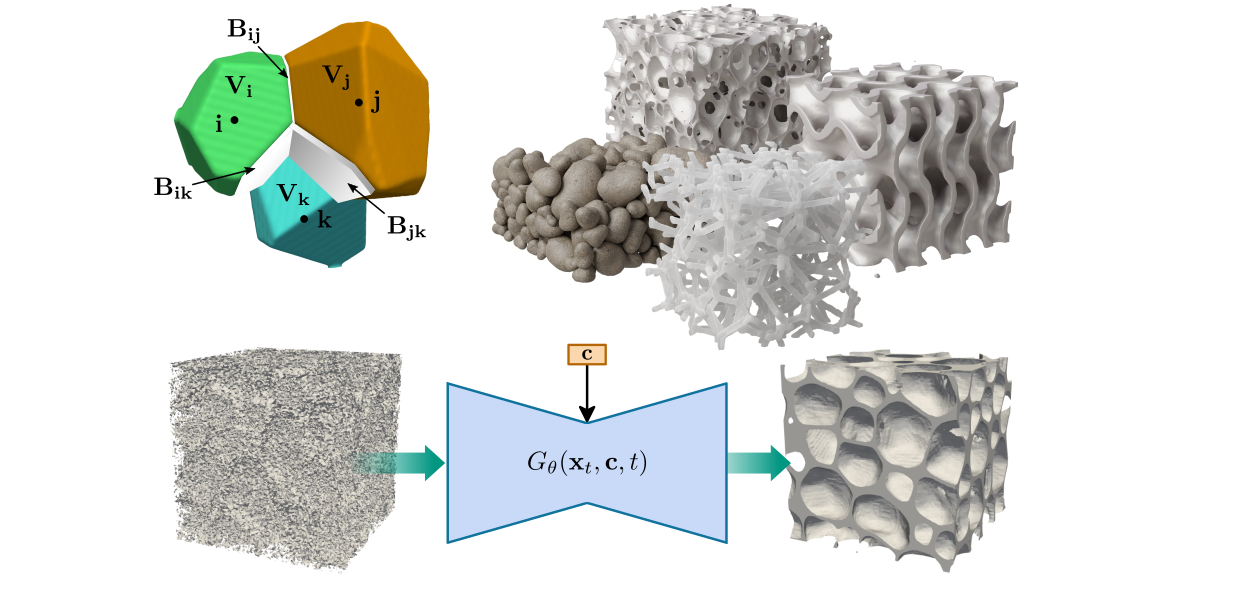

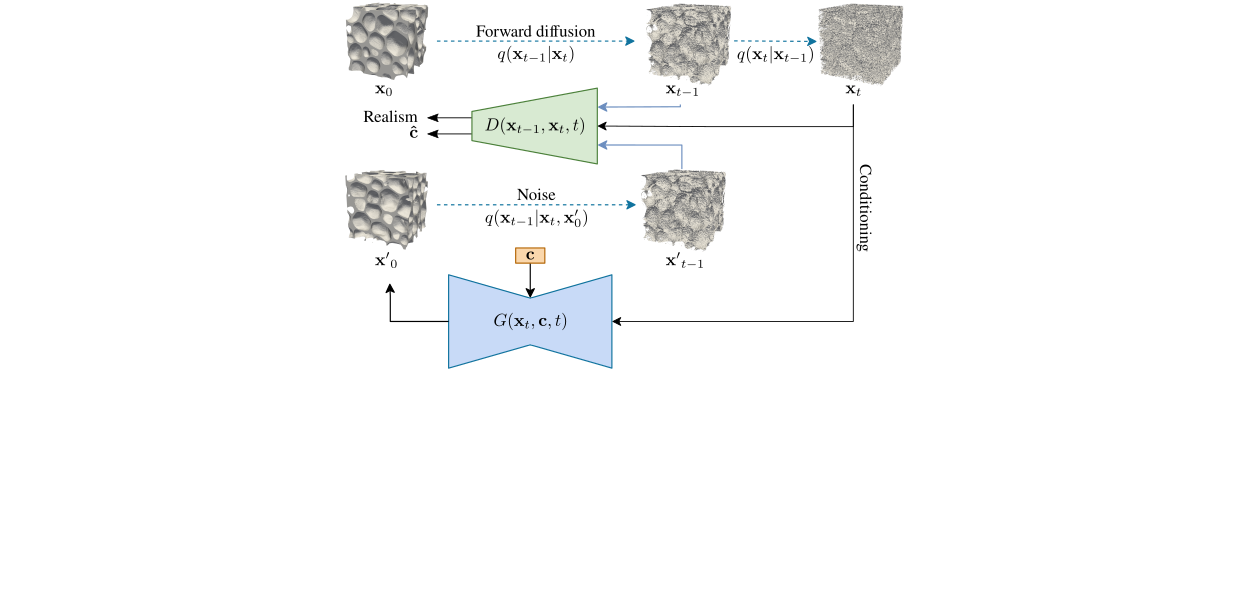

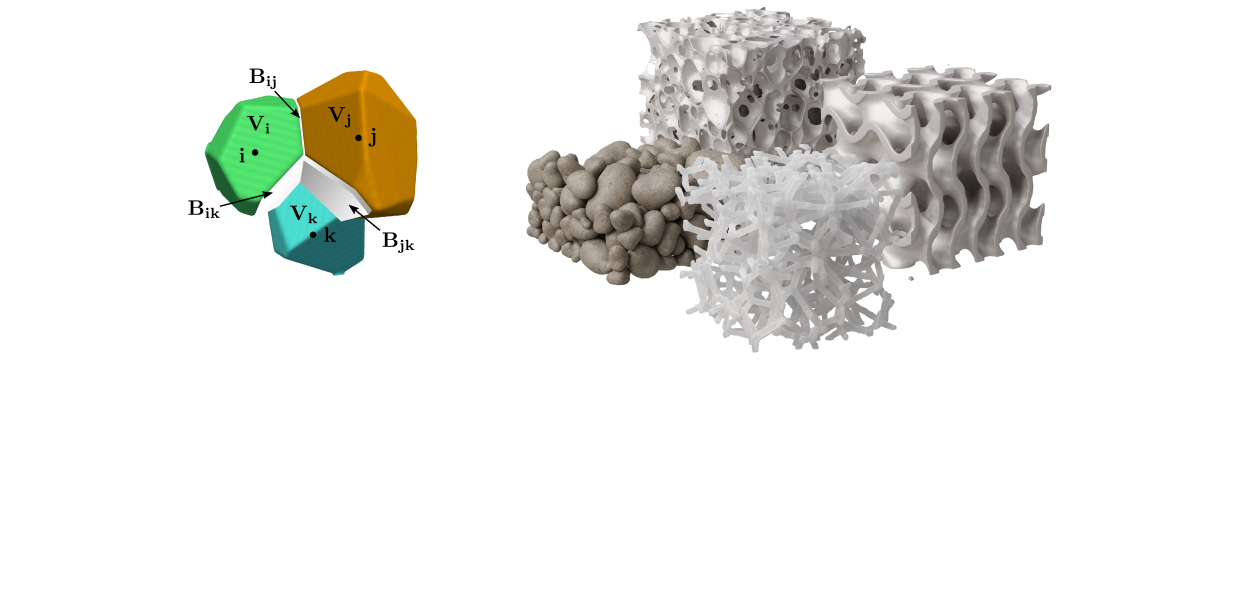

Various methodological approaches are employed for the generation of synthetic microstructures. Simulation-based strategies rely on the phase-field method, while geometry-based techniques such as Voronoi constructions or packing algorithms enable the direct parametrization of structural properties. In addition, generative AI, particularly diffusion models and variational autoencoders, is used, building on reconstructed digital twins to enable rapid and tunable synthesis of realistic variants. In this way, arbitrary microstructures can be generated synthetically.

Workflows

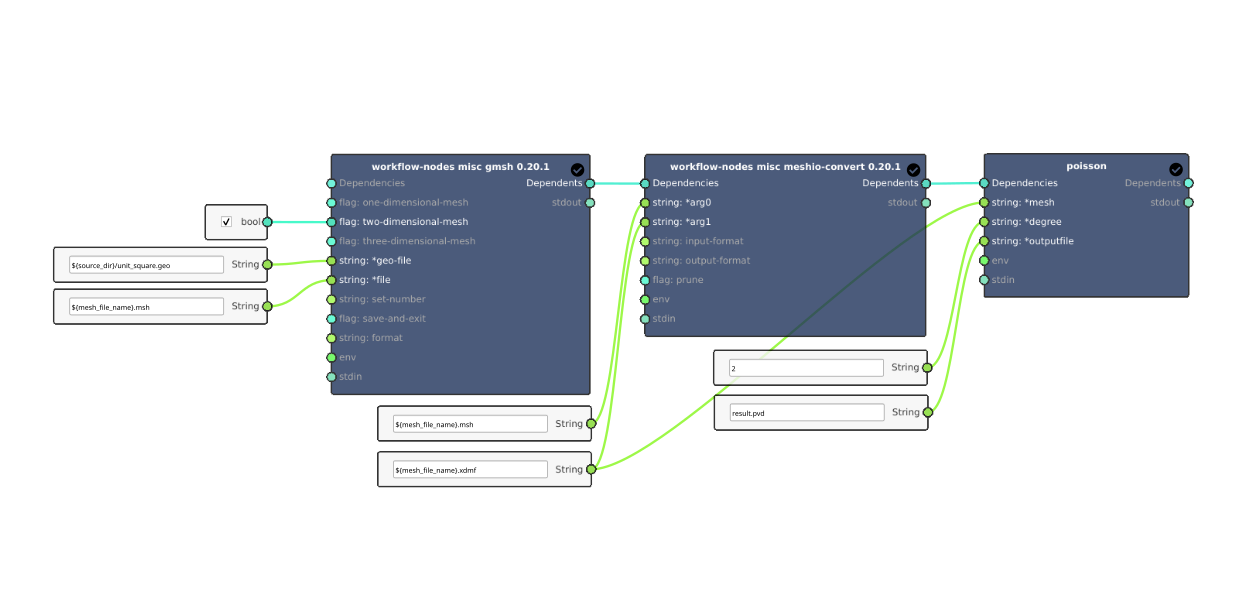

Zur Automatisierung der entwickelten Methoden, von der Segmentierung und Rekonstruktion bis hin zur Charakterisierung und Struktursynthese, werden in Zusammenarbeit mit der Forschungsgruppe Forschungsdatenmanagement reproduzierbare Workflows entwickelt. Mithilfe des KadiStudio-Workflow-Editors werden generische Prozessketten modelliert und in FAIR-konformer Weise ausführbar gemacht. Die modulare Struktur dieser Workflows ermöglicht deren Wiederverwendung in unterschiedlichen Anwendungsszenarien und gewährleistet eine effiziente Analyse großer und heterogener Datensätze.

| Name | Function |

|---|---|

| Griem, Lars Christoph | Group leader |

| Steinhülb, Johannes | Group leader |

| Name | Function |

|---|---|

| Kocak, Muhammed Saadeddin | Research Assistant |

Grolig, J.; Griem, L.; Selzer, M.; Kauczor, H.-U.; Triphan, S. M. F.; Nestler, B.; Koeppe, A.

2026. Materials Today Communications, 51, 114817. doi:10.1016/j.mtcomm.2026.114817

Griem, L.

2026. KIT Scientific Publishing. doi:10.5445/KSP/1000187467

Griem, L.

2025, November 14. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000186848

Griem, L.; Koeppe, A.; Greß, A.; Feser, T.; Nestler, B.

2025. Acta Materialia, 296, 121220. doi:10.1016/j.actamat.2025.121220

Leutz-Schmidt, P.; Grolig, J.; Wucherpfennig, L.; Sommerburg, O.; Eichinger, M.; Wege, S.; Graeber, S. Y.; Schenk, J.-P.; Alrajab, A.; Kauczor, H.-U.; Stahl, M.; Mall, M. A.; Koeppe, A.; Nestler, B.; Selzer, M.; Triphan, S. M. F.; Wielpütz, M. O.

2025. European Radiology, 35 (10), 6217–6228. doi:10.1007/s00330-025-11589-y

Griem, L. C.; Koeppe, A. H.; Selzer, M.; Nestler, B.

2024, October 9. Materials Process Applications Seminar (MPA 2024), Universität Stuttgart, October 8–10, 2024

Ji, Y.; Koeppe, A.; Altschuh, P.; Griem, L.; Rajagopal, D.; Nestler, B.

2024. Physica Scripta, 99 (7), Art.-Nr.: 076010. doi:10.1088/1402-4896/ad52cf

Ji, Y.; Koeppe, A.; Altschuh, P.; Rajagopal, D.; Zhao, Y.; Chen, W.; Chen, W.; Zhang, Y.; Zheng, Y.; Nestler, B.

2024. Computational Materials Science, 232, Art.-Nr.: 112628. doi:10.1016/j.commatsci.2023.112628

Altschuh, P.; Bräse, S.; Hartmann, T.; Jaeger, D.; Jung, N.; Koeppe, A.; Krauss, P.; Leister, C.; Nestler, B.; Schiefer, G.; Schreiber, C.; Selzer, M.; Starmann, M.; Tosato, G.

2023. E-Science-Tage 2023: Empower Your Research – Preserve Your Data. Ed.: Vincent Heuveline, Nina Bisheh, Philipp Kling, 264–269, heiBOOKS. doi:10.11588/heibooks.1288.c18086

Griem, L. C.; Thelen, R.; Selzer, M.

2023. Proceedings of the Conference on Research Data Infrastructure, 1. doi:10.52825/cordi.v1i.411

Al-Salman, R.; Teixeira, C. A.; Zschumme, P.; Lee, S.; Griem, L.; Aghassi-Hagmann, J.; Kirchlechner, C.; Selzer, M.

2023. Data Science Journal, 22, Art.-Nr.: 21. doi:10.5334/dsj-2023-021

Zhao, Y.; Altschuh, P.; Santoki, J.; Griem, L.; Tosato, G.; Selzer, M.; Koeppe, A.; Nestler, B.

2023. Acta Materialia, 253, Art.-Nr.: 118922. doi:10.1016/j.actamat.2023.118922

Griem, L. C.; Koeppe, A. H.; Feser, T.; Selzer, M.; Beeh, E.; Nestler, B.

2023, June. Helmholtz Artificial Intelligence Conference (Helmholtz AI 2023), Hamburg, Germany, June 12–14, 2023

Kunz, W.; Altschuh, P.; Bremerich, M.; Selzer, M.; Nestler, B.

2023. Materials Today Communications, 35, Art.-Nr.: 106004. doi:10.1016/j.mtcomm.2023.106004

Griem, L. C.; Greß, A.; Koeppe, A. H.; Feser, T.; Selzer, M.; Beeh, E.; Nestler, B.

2023, May 11. 1st International Seminar on Modelling, Simulation and Machine Learning for the rapid development of porous materials (2023), Cologne, Germany, May 10–12, 2023

Jamshidi, F.; Kunz, W.; Altschuh, P.; Lu, T.; Laqua, M.; August, A.; Löffler, F.; Selzer, M.; Nestler, B.

2023. Materials Today Communications, 34, Art.-Nr.: 105413. doi:10.1016/j.mtcomm.2023.105413

Ji, Y.; Koeppe, A.; Altschuh, P.; Griem, L.; Rajagopal, D.; Nestler, B.; Chen, W.; Zhang, Y.; Zheng, Y.

2023. doi:10.48550/arXiv.2310.20379

Altschuh, P.; Bräse, S.; Hartmann, T.; Jaeger, D.; Jung, N.; Krauss, P.; Leister, C.; Nestler, B.; Schiefer, G.; Schreiber, C.; Selzer, M.; Starman, M.; Tosato, G.; Koeppe, A.

2023. E-Science-Tage 2023: Empower Your Research – Preserve Your Data (2023), Heidelberg, Germany, March 1–3, 2023. doi:10.11588/heidok.00033126

Griem, L. C.; Greß, A.; Altschuh, P.; Feser, T.; Koeppe, A. H.; Selzer, M.; Nestler, B.

2022, September 28. Materials Science and Engineering Congress (MSE 2022), Darmstadt, Germany, September 27–29, 2022

Griem, L.; Zschumme, P.; Laqua, M.; Brandt, N.; Schoof, E.; Altschuh, P.; Selzer, M.

2022. Data Science Journal, 21 (1), Art.-Nr: 16. doi:10.5334/dsj-2022-016

Griem, L. C.; Greß, A.; Altschuh, P.; Feser, T.; Selzer, M.; Beeh, E.; Nestler, B.

2022, June. Helmholtz Artificial Intelligence Conference (Helmholtz AI 2022), Dresden, Germany, June 2–3, 2022

Jamshidi, F.; Kunz, W.; Altschuh, P.; Bremerich, M.; Przybylla, R.; Selzer, M.; Nestler, B.

2022. Physics of Fluids, 34 (6), Art.-Nr.: 062110. doi:10.1063/5.0093316

Brandt, N.; Garabedian, N. T.; Schoof, E.; Schreiber, P. J.; Zschumme, P.; Greiner, C.; Selzer, M.

2022. Data, 7 (2), Art.-Nr. 15. doi:10.3390/data7020015

Altschuh, P.; Kunz, W.; Bremerich, M.; Reiter, A.; Selzer, M.; Nestler, B.

2022. Membranes, 12 (7), 638. doi:10.3390/membranes12070638

Wallat, L.; Altschuh, P.; Reder, M.; Nestler, B.; Poehler, F.

2022. Materials, 15 (10), Art.-Nr.: 3730. doi:10.3390/ma15103730

Griem, L. C.; Koeppe, A. H.; Altschuh, P.; Schoof, E.; Brandt, N.; Zschumme, P.; Selzer, M.; Nestler, B.

2021, November 30. Euromembrane (2021), Copenhagen, Denmark, November 28–December 2, 2021

Wang, F.; Ratke, L.; Zhang, H.; Altschuh, P.; Nestler, B.

2021. Journal of sol gel science and technology, 99 (1), 273. doi:10.1007/s10971-021-05565-3

Brandt, N.; Griem, L.; Herrmann, C.; Schoof, E.; Tosato, G.; Zhao, Y.; Zschumme, P.; Selzer, M.

2021. Data science journal, 20 (1), Art.-Nr.: 8. doi:10.5334/dsj-2021-008

Altschuh, P.; Bach, F.; Bräse, S.; Hartmann, T.; Jung, N.; Krauß, P.; Nestler, B.; Schiefer, G.; Schreiber, C.; Selzer, M.; Terzijska, D.

2021. E-Science-Tage 2019: Data to Knowledge (2021), Heidelberg, Germany, March 4–5, 2021

Altschuh, P.; Bach, F.; Bräse, S.; Hartmann, T.; Jung, N.; Krauß, P.; Nestler, B.; Schiefer, G.; Schreiber, C.; Selzer, M.; Terzijska, D.

2021. E-Science-Tage 2021: Share Your Research Data, Heidelberg, 04.03. - 05.03.2021. doi:10.11588/heidok.00029699

Herrmann, C.; Schneider, D.; Schoof, E.; Schwab, F.; Nestler, B.

2021. Materials, 14 (17), Art.-Nr.: 4956. doi:10.3390/ma14174956

Daubner, S.; Kubendran Amos, P. G.; Schoof, E.; Santoki, J.; Schneider, D.; Nestler, B.

2021. Physical review materials, 5 (3), Article no: 035406. doi:10.1103/PhysRevMaterials.5.035406

Schoof, E.

2021. KIT Scientific Publishing. doi:10.5445/KSP/1000123341

Altschuh, P.

2020, August 26. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000122904

Yabansu, Y. C.; Altschuh, P.; Hötzer, J.; Selzer, M.; Nestler, B.; Kalidindi, S. R.

2020. Acta materialia, 195, 668–680. doi:10.1016/j.actamat.2020.06.003

Wang, F.; Ratke, L.; Zhang, H.; Altschuh, P.; Nestler, B.

2020. Journal of sol gel science and technology, 94 (1), 356–374. doi:10.1007/s10971-020-05238-7

Schoof, E.

2020, April 1. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000117917

Schoof, E.; Kubendran Amos, P. G.; Schneider, D.; Nestler, B.

2020. Materialia, 9, Article: 100620. doi:10.1016/j.mtla.2020.100620

Mushongera, L. T.; Amos, P. G. K.; Schoof, E.; Kumar, P.; Nestler, B.

2020. Journal of materials science, 55, 5280–5295. doi:10.1007/s10853-019-04307-9

Kubendran Amos, P. G.; Schoof, E.; Santoki, J.; Schneider, D.; Nestler, B.

2020. Computational materials science, 173, Article No.109388. doi:10.1016/j.commatsci.2019.109388

Kellner, M.; Hötzer, J.; Schoof, E.; Nestler, B.

2020. Acta materialia, 182, 267–277. doi:10.1016/j.actamat.2019.10.028

Rheinheimer, W.; Schoof, E.; Selzer, M.; Nestler, B.; Hoffmann, M. J.

2019. Acta materialia, 174, 105–115. doi:10.1016/j.actamat.2019.05.040

Wang, F.; Altschuh, P.; Ratke, L.; Zhang, H.; Selzer, M.; Nestler, B.

2019. Advanced materials, 31 (26), Art.Nr. 1806733. doi:10.1002/adma.201806733

Schoof, E.; Herrmann, C.; Streichhan, N.; Selzer, M.; Schneider, D.; Nestler, B.

2019. Modelling and simulation in materials science and engineering, 27 (2), 025010. doi:10.1088/1361-651X/aaf980

Amos, P. G. K.; Schoof, E.; Schneider, D.; Nestler, B.

2019. Proceedings of the 1st International Conference on Numerical Modelling in Engineering – Volume 2: Numerical Modelling in Mechanical and Materials Engineering, NME 2018, 28-29 August 2018, Ghent University, Belgium. Ed.: M. Abdel Wahab, 47–63, Springer. doi:10.1007/978-981-13-2273-0_5

Schoof, E.; Herrmann, C.; Schneider, D.; Hötzer, J.; Nestler, B.

2019. High Performance Computing in Science and Engineering ’18. Ed.: W. Nagel, 475–488, Springer International Publishing. doi:10.1007/978-3-030-13325-2_30

Wang, F.; Altschuh, P.; Matz, A. M.; Heimann, J.; Matz, B. S.; Nestler, B.; Jost, N.

2019. Acta materialia, 170, 138–154. doi:10.1016/j.actamat.2019.03.008

Kubendran Amos, P. G.; Schoof, E.; Streichan, N.; Schneider, D.; Nestler, B.

2019. Computational materials science, 159, 281–296. doi:10.1016/j.commatsci.2018.12.023

Herrmann, C.; Schoof, E.; Schneider, D.; Schwab, F.; Reiter, A.; Selzer, M.; Nestler, B.

2018. Computational mechanics, 62 (6), 1399–1412. doi:10.1007/s00466-018-1570-0

Kubendran Amos, P. G.; Schoof, E.; Schneider, D.; Nestler, B.

2018. Journal of alloys and compounds, 767, 1141–1154. doi:10.1016/j.jallcom.2018.07.138

Kulkarni, N.; Herrmann, C.; Schoof, E.; Hoffrogge, P.; Schneider, D.; Nestler, B.; Schwab, R.

2018, May 11. International Materials Science Winter School (2018), Karlsruhe, Germany, November 5, 2018

Schoof, E.; Schneider, D.; Streichhan, N.; Mittnacht, T.; Selzer, M.; Nestler, B.

2018. International journal of solids and structures, 134, 181–194. doi:10.1016/j.ijsolstr.2017.10.032

Schneider, D.; Schoof, E.; Tschukin, O.; Reiter, A.; Herrmann, C.; Schwab, F.; Selzer, M.; Nestler, B.

2018. Computational mechanics, 61 (3), 297. doi:10.1007/s00466-017-1485-1

Schneider, D.; Schoof, E.; Tschukin, O.; Reiter, A.; Herrmann, C.; Schwab, F.; Selzer, M.; Nestler, B.

2018. Computational mechanics, 61 (3), 277–295. doi:10.1007/s00466-017-1458-4

Kubendran Amos, P. G.; Schoof, E.; Schneider, D.; Nestler, B.

2018. Acta materialia, 159, 51–64. doi:10.1016/j.actamat.2018.08.009

Ley, A.; Altschuh, P.; Thom, V.; Selzer, M.; Nestler, B.; Vana, P.

2018. Journal of membrane science, 564, 543–551. doi:10.1016/j.memsci.2018.07.062

Schoof, E.; Streichhan, N.; Schneider, D.; Selzer, M.; Nestler, B.

2017. Forschung aktuell, 13–16

Schneider, D.; Schoof, E.; Schwab, F.; Herrmann, C.; Selzer, M.; Nestler, B.

2017. 4th GAMM Workshop on Phase Field Modeling, RWTH Aachen University, Germany, 2nd - 3rd February 2017

Altschuh, P.; Yabansu, Y. C.; Hötzer, J.; Selzer, M.; Nestler, B.; Kalidindi, S. R.

2017. Journal of membrane science, 540, 88–97. doi:10.1016/j.memsci.2017.06.020

Schneider, D.; Schwab, F.; Schoof, E.; Reiter, A.; Herrmann, C.; Selzer, M.; Böhlke, T.; Nestler, B.

2017. Computational mechanics, 60 (2), 203–217. doi:10.1007/s00466-017-1401-8

Schneider, D.; Schoof, E.; Tschukin, T.; Schwab, F.; Selzer, M.; Nestler, B.

2016. Interdisziplinäres Seminar Mathematik und Mechanik, Kaiserslautern, Deutschland, 2016

Schneider, D.; Schoof, E.; Schwab, F.; Selzer, M.; Nestler, B.

2016. EMMC15 : 15th European Mechanics of Materials Conference, Brussel, Belgium, 7th - 9th September 2016

Schneider, D.; Schoof, E.; Schwab, F.; Selzer, M.; Nestler, B.

2016. ECCOMAS 2016 : European Congress on Computational Methods in Applied Sciences and Engineering, Crete Island, Greece, 5th - 10th June 2016

Schneider, D.; Schoof, E.; Reiter, A.; Selzer, M.; Nestler. B.

2016. The 22nd International Symposium on Plasticity and Its Current Applications, Sheraton Kona Resort & Spa Keauhou Bay, Hawaii, 3rd - 9th January 2016

Schneider, D.; Schoof, E.; Huang, Y.; Selzer, M.; Nestler, B.

2016. Computer methods in applied mechanics and engineering, 312, 186–195. doi:10.1016/j.cma.2016.04.009

Nestler, B.; Schneider, D. M.; Schoof, E.; Huang, Y.; Selzer, M.

2016. GAMM-Mitteilungen, 39 (1), 78–91. doi:10.1002/gamm.201610005

Schneider, D.; Tschukin, O.; Schoof, E.; Choudhury, A.; Selzer, M.; Nestler, B.

2015. PTM 2015 : International Conference on Solid-Solid Phase Transformations in Inorganic Materials, Westin Whistler Resort & Spa, Canada, 28th June - 3rd July 2015

Schneider, D.; Tschukin, O.; Schoof, E.; Choudhury, A.; Selzer, M.; Nestler, B.

2015. ICM12 : 12th International Conference on the Mechanical Behavior of Materials, Karlsruhe, Germany, 10th - 14th May 2015

Ettrich, J.; Choudhury, A.; Tschukin, O.; Schoof, E.; August, A.; Nestler, B.

2014. Modelling and simulation in materials science and engineering, 22 (8), Art.Nr. 085006/1–29. doi:10.1088/0965-0393/22/8/085006

Schoof, E.; Römmelt, M.; Selzer, M.; August, A.; Nestler, B.; Kneer, A.; Stegmaier, T.

2012. International School and Conference on Biological Materials Science, Potsdam, March 20-23, 2012