Dr. Anastasia August

- Room: 110.2

CS 30.48 - Phone: +49 721 608-45313

- anastasia august2 ∂does-not-exist.kit edu

IAM-MMS, Gruppenleitung:

Multiphysics Materials Modelling: Microstructure - Heat and Mass Transfer

Institut für Angewandte Materialien

Mikrostruktur-Modellierung und Simulation (IAM-MMS)

MZE - Geb. 30.48

Straße am Forum 7

76131 Karlsruhe

Research

Modelling heat transfer in porous structures, under the influence of fluid flow, among other things

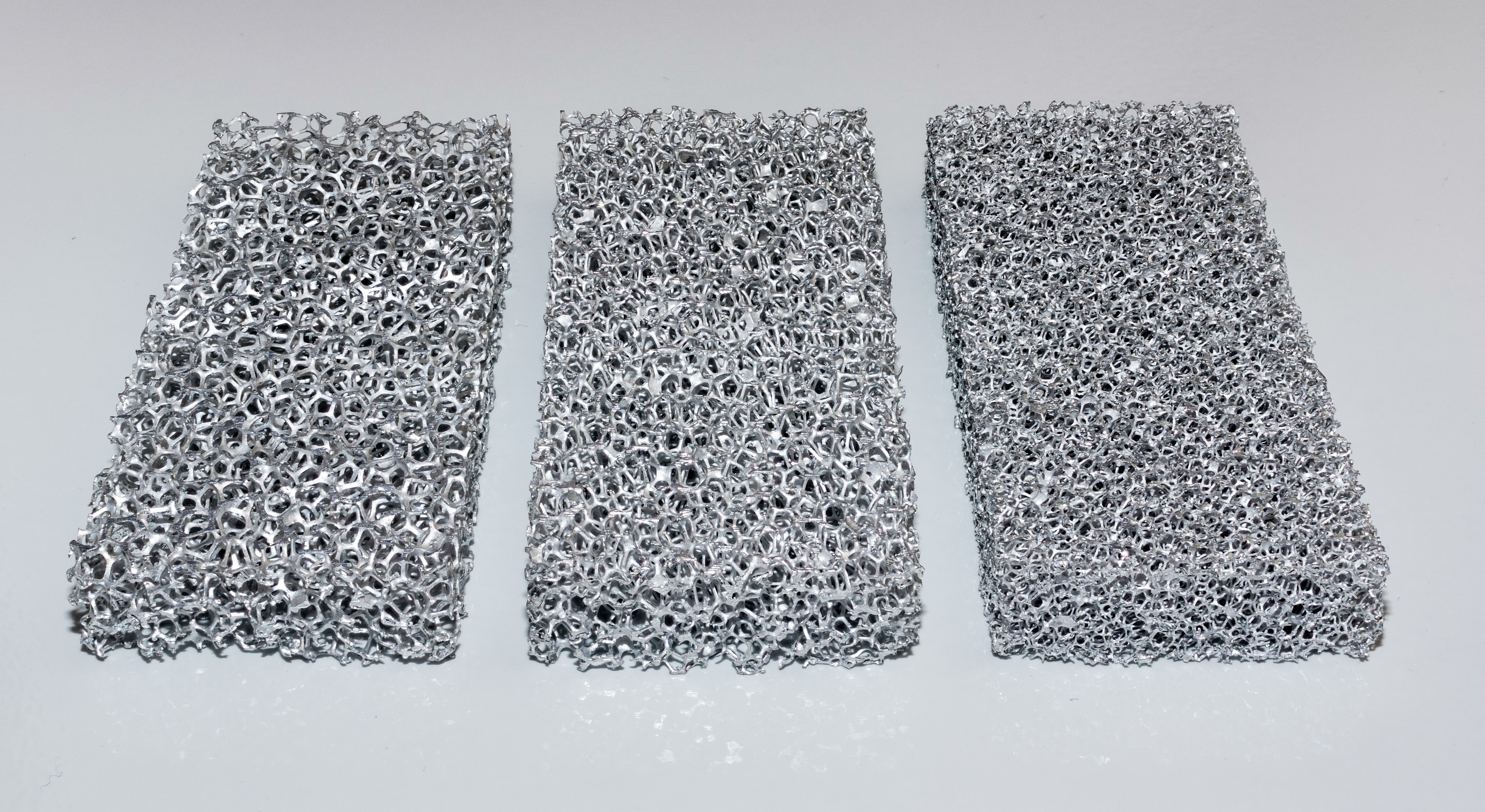

The research activities of the working group “Multiphysics Materials Modelling: Microstructure – Heat and Mass Transfer”, led by Dr. rer. nat. Anastasia August, include the modelling of the heat transfer in porous structures, which, among other things, is influenced by fluid flow. The improvement of the efficiency of heat exchangers, heat collectors and heat storage systems, in dependence of the microstructure and the material properties, is the objective of the work. During the reproduction of the processes, the phase transformation processes of the fluid medium are considered. The work of the research group focuses on the development of an optimal structure of the participating porous materials, such as the structure of a metal foam.

Photograph: Dr. Marco Berghoff

Important Research Projects

Metal foams

Metal foams are materials with excellent properties. They look like beer froth, but without the beer, and basically without partitions between the individual bubbles. Only where three or more bubbles meet is it that material still does exist. These so-called ligaments form an irregular solid mesh, which still possesses many properties of the base material – metal: thermal conductivity, stability, electrical conductivity, and even more properties, such as the lightness, the reduced demand for base material, and especially the large surface, compared to the volume. This surface, for example, enables the heat to be exchanged by the air, which surrounds the ligaments. Because of this property, in connection with the good thermal conductivity of metal, metal foams are very popular in our research within the KIT programme “Energy Efficiency, Materials and Resources”.

Link: http://www.emr.kit.edu/ ![]()

Solar thermal energy

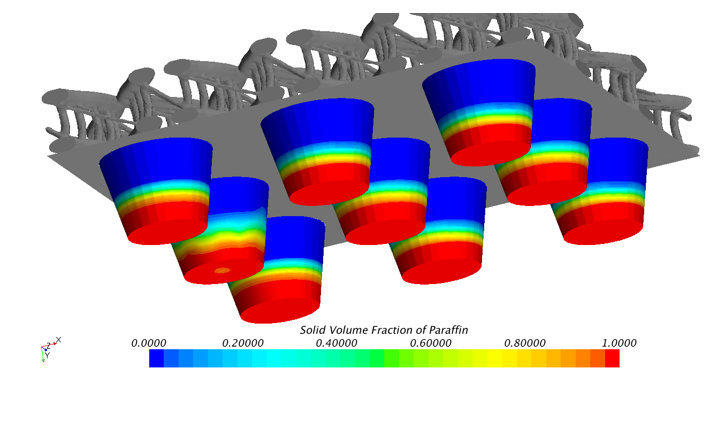

Black objects are able to absorb solar energy extremely well. The skin of a polar bear is black, so that it is able to absorb as much energy as possible from the sunlight at the North Pole. The white hairs of its fur, which allow the sunlight to pass through, serve as an insulation of the polar bear's own body heat. On the basis of this principle, heat collectors, consisting of textile spacer fabrics, are developed in the project “Solar Thermal Energy”, in cooperation with the Institute of Textile Technology and Process Engineering, Denkendorf https://www.uni-stuttgart.de/forschung/orp/inst_profile/we/itv.html, which is the project partner. Besides the generation of energy, the storage of energy does, of course, also play an important role. In the second part of the project, new storage systems are examined: small, thimble-sized buckets, filled with paraffin, which are to be positioned directly beneath the textile collector. During melting, paraffin stores the latent heat, and releases it again during solidification. At the CMS, we examine the eligible systems by means of computer simulations, and make suggestions for improvement, with regard to their geometry.

Porous water pipes

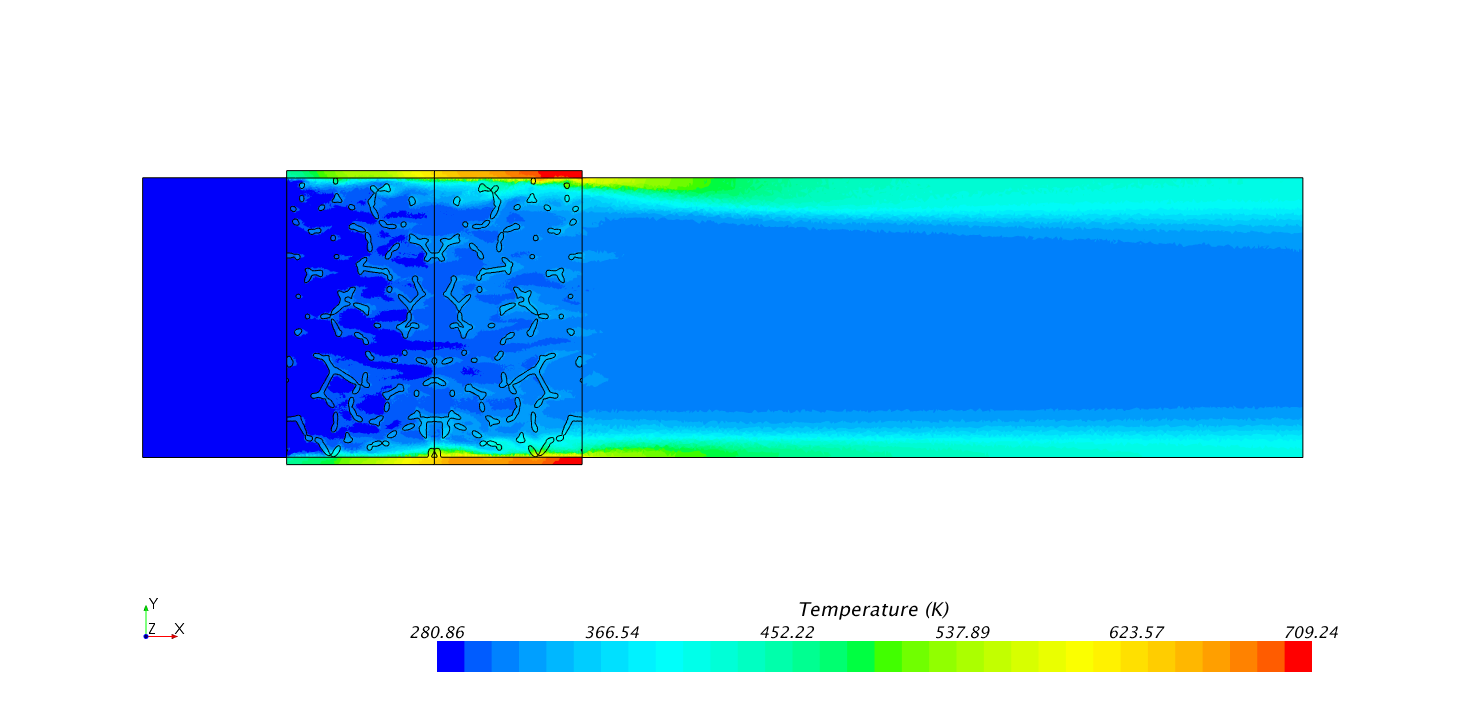

Using energy resources in the most efficient manner is an important challenge of the future. In materials sciences, this results in a search for efficient, affordable and practical materials for heat conduction and storage. Metal foams provide a promising solution for energy transmission and energy storage problems, as they possess the capacity to allow fluids to permeate, on the one hand, and a large surface, on the other hand. This enables fluids and other possible fillings to be heated more efficiently. Hereby, the objective is to achieve a heat transfer, which is as high as possible, while, at the same time, the pressure drop is as low as possible. First, these foams are designed in computer simulations, in which the material is tested for different conditions, such as changes in temperature or pressure, as well as for the influence of different pore sizes. Subsequently, a 3D printer is used to produce a model for the investment casting of the optimal foam.

Metal foams are used in the design of water pipes, which release their energy to the water in a more efficient manner.

InSel: Innovative foam structures for an efficient lightweight design

The research project InSel (innovative foam structures for an efficient lightweight design) is a research initiative in Baden-Wuerttemberg, for research on lightweight design, which consists of an association of different universities, extramural institutions and companies, in which the IAM of the KIT is involved. It includes joint research, but also the communication of research results to companies, as well as the networking of the members of the project InSel with other research projects. Thereby, the following three aspects are of primary importance for the members of the project InSel:

Innovation:

Because of the steady advancement of technology, porous structures are popular materials, whose development, however, poses a challenge, such as the development of composites.

Economy:

The project InSel is supposed to enable the development of porous materials, which so far have not been developed sufficiently. This especially increases the competitiveness of medium-sized companies.

Communication:

This aspect includes the communication of knowledge to other companies. Moreover, with this interdisciplinary approach, the communication among researchers is to be strengthened.

Subproject:

At the CMS, we participate in the project by performing computer simulations in the field of polymer foams, which serve as preforms during the casting of particularly fine-pored and monodisperse metal foams.

Link:https://www.hs-pforzheim.de/insel

| Titel | chair | Referent |

|---|---|---|

| Farmelab | Metallschaum Teil 1: Youtube Metallschaum Teil 2: Youtube Wärmeleitfähigkeit: Youtube Nebelfänger Teil 1: Youtube Nebelfänger Teil 2: Youtube Eisbär Teil 1: Youtube Eisbär Teil 2: Youtube Talking Science: Karlsruhe-Blog Famelab: clickit-magazin |

|

| Science Slam | Metallschaum und Paraffin: Youtube Stetigkeit: Youtube Eisbär: Feeds Video Uni-Erlangen |

|

| Podcast | Podcast: Math KIT |

Publikationsliste 3047

-

Development and numerical investigation of metal foam based modular latent heat storage cell

Kneer, A.; August, A.; Nestler, B.; Martens, E.

2013. 2nd International Conference on Materials for Energy (EnMat 2013), Karlsruhe, 12.-16. Mai 2013 -

Thermal conductivity of air filled open cell aluminum foams

August, A.; Nestler, B.; Rölle, M.; Schmid, S.; Ettrich, J.

2013. 2nd International Conference on Materials for Energy (EnMat 2013), Karlsruhe, 12.-16. Mai 2013 -

Thermal conductivity of air filled open cell aluminum foams

August, A.; Nestler, B.; Rölle, M.; Schmid, S.; Ettrich, J.

2012. Biannual Internat.Conf.on Materials Science Engineering (MSE 2012), Darmstadt, September 25-27, 2012 -

Computational analysis of bio inspired thermal absorber systems made of textile fabrics

Schoof, E.; Römmelt, M.; Selzer, M.; August, A.; Nestler, B.; Kneer, A.; Stegmaier, T.

2012. International School and Conference on Biological Materials Science, Potsdam, March 20-23, 2012 -

Phase-field study of the fragmentation secondary arm in Al-Cu alloys

Wesner, E.; Choudhury, A.; August, A.; Berghoff, M.; Nestler, B.

2011. Euromat 2011 : European Congress and Exhibition on Advanced Materials and Processes, Montpellier, F, September 12-15, 2011 -

Eigenspannungsentwicklung in metallischen Schäumen

August, A.

2010. Nachwuchsakademie ’Analyse und Bewertung von Eigenspannungen auf unterschiedlichen Längenskalen’, Kassel, 15.Oktober 2010 -

Efficiency study of metal foams for heat storage and heat exchange

August, A.; Nestler, B.; Wendler, F.; Selzer, M.; Kneer, A.; Martens, E.

2010. 5th Internat.Conf.on Multiscale Materials Modeling (MMM 2010), Freiburg, October 4-8, 2010

-

Simulation der Eigenspannungsentwicklung in metallischen Schäumen

August, A.

2015. Nachwuchsakademie ’Analyse und Bewertung von Eigenspannungen auf unterschiedlichen Längenskalen’, Kassel, 24.-28.Mai 2010 -

Digital representation of complex cellular structures for numerical simulations

Ettrich, J.; August, A.; Roelle, M.; Nestler, B.

2014. Cellular Materials (CellMAT 2014), Dresden, October 22-24, 2014 -

Open cell metal foams: Measurement and numerical modelling of fluid flow and heat transfer

Ettrich, J.; August, A.; Nestler, B.

2014. Cellular Materials (CellMAT 2014), Dresden, October 22-24, 2014 -

A numerical approach to derive analytical correlations for pressure drop and heat transfer for open cell porosities

August, A.; Kneer, A.; Janßen-Tapken, K.; Nestler, B.

2014. Cellular Materials (CellMAT 2014), Dresden, October 22-24, 2014 -

Advanced coupled simulation methods for heat transfer and stiffnessphenomena induced by fluid flow in metal foams

Kneer, A.; Janssen-Tapken, K.; Reimann, K.; August, A.; Nestler, B.

2013. 5th International Conference on Computational Methods for Coupled Problems in Sciennce and Engineering, Santa Eulalia, Ibiza, E, June 17-19, 2013 -

Metallische Schäume: Aktuelle Projekte am KIT-ZBS

August, A.

2012. Nachwuchsakademie ’Analyse und Bewertung von Eigenspannungen auf unterschiedlichen Längenskalen’, Kassel, 23.-24.April 2012 -

Metallic foam structures, dendrites and implementation optimizations for phase-field modeling

Vondrous, A.; Nestler, B.; August, A.; Wesner, E.; Choudhury, A.; Hötzer, J.

2011. High Performance Computing in Science and Engineering, Stuttgart, October 4-5, 2011 -

Simulation of heat propagation in open cell metal foams

August, A.

2011. Euromat 2011 : European Congress and Exhibition on Advanced Materials and Processes, Montpellier, F, September 12-15, 2011 -

Phase field simulations of heat propagation in open cell metal foam

August, A.

2011. Materials Research Society Spring Meeting, San Francisco, Calif., April 25-29, 2011 -

Analysis of thermal evolution in textile fabrics using advanced microstructure simulation techniques

Römmelt, M.; August, A.; Nestler, B.; Kneer, A.

2011. 5th Internat.Conf.on Textile Composites and Inflatable Structures (Structural Membranes 2011), Barcelona, E, October 5-7, 2011 -

Efficiency study of metal foams for heat storage and heat exchange

August, A.

2010. International Conference on Cellular Materials (CellMat 2010), Dresden, October 27-29, 2010

-

Phase-field simulations of large-scale microstructures by integrated parallel algorithms

Hötzer, J.; Jainta, M.; Vondrous, A.; Ettrich, J.; August, A.; Stubenvoll, D.; Reichardt, M.; Selzer, M.; Nestler, B.

2015. High Performance Computing in Science and Engineering ’14 : Transactions of the High Performance Computing Center, Stuttgart (HLRS), 2014. Hrsg.: W. E. Nagel, 629–644, Springer. doi:10.1007/978-3-319-10810-0_41 -

Digital representation of complex cellular structures for numerical simulations

Ettrich, J.; August, A.; Roelle, M.; Nestler, B.

2014. Cellular Materials (CellMAT 2014), Dresden, 22.-24. Oktober 2014, CD-ROM -

Open cell metal foams: Measurement and numerical modelling of fluid flow and heat transfer

Ettrich, J.; August, A.; Nestler, B.

2014. Cellular Materials (CellMAT 2014), Dresden, 22.-24. Oktober 2014, CD-ROM -

Metallic foam structures, dendrites and implementation optimizations for phase-field modeling

Vondrous, A.; Nestler, B.; August, A.; Wesner, E.; Choudhury, A.; Hötzer, J.

2012. High performance computing in science and engineering ’ 11 : transactions of the High Performance Computing Center, Stuttgart (HLRS) 2011. Ed.: W.E. Nagel, 595–606, Springer-Verlag. doi:10.1007/978-3-642-23869-7_43 -

Analysis of thermal evolution in textile fabrics using advanced microstructure simulation techniques

Römmelt, M.; August, A.; Nestler, B.; Kneer, A.

2011. 5th Internat.Conf.on Textile Composites and Inflatable Structures (Structural Membranes 2011), Barcelona, E, October 5-7, 2011. Ed.: E. Onate, 614–626 -

Efficiency Study of Metal Foams for Heat Storage and Heat Exchange

August, A.; Nestler, B.; Wendler, F.; Selzer, M.; Kneer, A.; Martens, E.

2010. CELLMAT 2010 : Proceedings of the International Conference on Cellular Materials, Dresden, Germany, October 27 - 29, 2010. Ed.: G. Stephan, 148–151, Fraunhofer Institute for Manufacturing Technology and Advanced Materials -

Efficiency study of metal foams for heat storage and heat exchange

August, A.; Nestler, B.; Wendler, F.; Selzer, M.; Kneer, A.; Martens, E.

2010. Gumbsch, P. [Hrsg.] Proc.of the 5th Internat.Conf.on Multiscale Materials Modeling (MMM 2010), Freiburg, October 4-8, 2010 Stuttgart : Fraunhofer Verl., 2010, 355–358

-

Kleine Bausteine mit großer Wirkung

Kneer, A.; August, A.; Wirtz, M.; Herrmann, C.; Schneider, D.; Nestler, B.

2021. Forschung aktuell, 44–51 -

About the surface area to volume relations of open cell foams

August, A.; Nestler, B.

2020. Engineering Research Express, 2 (1), Article No.015021. doi:10.1088/2631-8695/ab6ac6 -

Modern Times need Enlightened Innovation and Sophisticated Materials

Kneer, A.; Wirtz, M.; Yurtsever-Kneer, S.; Barbe, S.; August, A.

2019. Galvanotechnik, 2019 (4), 712–719 -

A bionic approach for heat generation and latent heat storage inspired by the polar bear

August, A.; Kneer, A.; Reiter, A.; Wirtz, M.; Sarsour, J.; Stegmaier, T.; Barbe, S.; Gresser, G. T.; Nestler, B.

2019. Energy, 168, 1017–1030. doi:10.1016/j.energy.2018.11.143 -

Effective Thermal Conductivity of Composite Materials Based on Open Cell Foams

August, A.; Reiter, A.; Kneer, A.; Selzer, M.; Nestler, B.

2018. Heat and Mass Transfer Research Journal, 2 (1), 33–45 -

Perspectives on material modelling: Porous and particle-based microstructures

Nestler, B.; August, A.; Selzer, M.; Hötzer, J.; Kellner, M.; Prajapati, N.; Rehn, V.; Seiz, M.

2018. Ceramic applications, 6 (1), 73–77 -

Sonnenbäder am Nordpol: Das Eisbär-Prinzip für Gebäude

August, A.; Nestler, B.; Kneer, A.

2015. Horizonte : Forschung an Fachhochschulen in Baden-Württemberg, (45), 68 -

Prediction of heat conduction in open-cell foams via the diffuse interface representation of the phase-field method

August, A.; Ettrich, J.; Rölle, M.; Schmid, S.; Berghoff, M.; Selzer, M.; Nestler, B.

2015. International Journal of Heat and Mass Transfer, 84, 800–808. doi:10.1016/j.ijheatmasstransfer.2015.01.052 -

Metallische Schneeflocken

Wesner, E.; August, A.; Nestler, B.

2014. Horizonte : Forschung an Fachhochschulen in Baden-Württemberg, (43), 29–31 -

Modelling of transient heat conduction with diffuse interface methods

Ettrich, J.; Choudhury, A.; Tschukin, O.; Schoof, E.; August, A.; Nestler, B.

2014. Modelling and simulation in materials science and engineering, 22 (8), Art.Nr. 085006/1–29. doi:10.1088/0965-0393/22/8/085006 -

A phase-field study of large-scale dendrite fragmentation in Al-Cu

Wesner, E.; Choudhury, A.; August, A.; Berghoff, M.; Nestler, B.

2012. Journal of crystal growth, 359 (1), 107–121. doi:10.1016/j.jcrysgro.2012.08.036 -

Comparison of phase-field and cellular automaton models for dendritic solidification in Al-Cu alloy

Choudhury, A.; Reuther, K.; Wesner, E.; August, A.; Nestler, B.; Rettenmayr, M.

2012. Computational materials science, 55, 263–268. doi:10.1016/j.commatsci.2011.12.019 -

Offenporige metallische Schäume

August, A.; Nestler, B.; Kneer, A.; Wendler, F.; Rölle, M.; Selzer, M.

2011. Werkstoffe in der Fertigung, 2011 (6), 45–46