Synthesis and Ceramic Powder Technology

The research activities of the Synthesis and Ceramic Powder Technology working group focus on application-orientated aspects of inorganic non-metallic materials. In addition to the development of new materials, the main focus is on understanding material-process-structure-property relationships. The potential of many materials is only realised through suitable doping, customised structures or composite materials. The following core competences of the working group are derived from this:

- Synthesis of inorganic-nonmetallic materials

- Powder proccessing technology

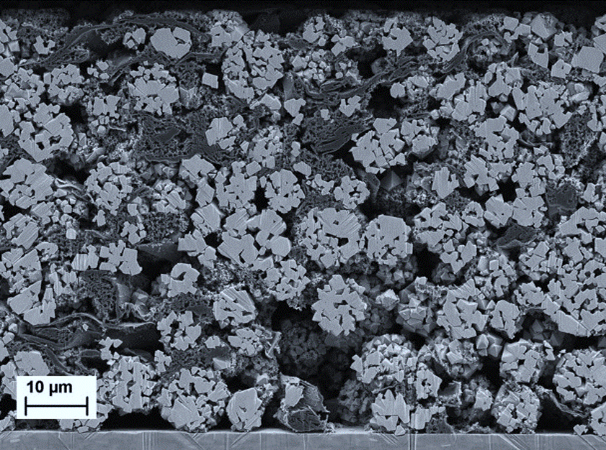

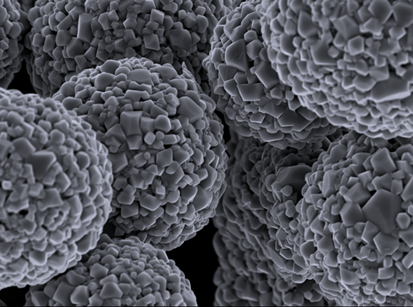

- Structural and morphological characterization of the materials

From the outset, processes are used in the production of the materials with which larger quantities can also be synthesised so that they can be further processed into application-relevant components or systems using appropriate process technologies.

Recent research activities are:

Materials for lithium-ion batteries

While the zero-strain mechanism is considered for lithium transition metal fluorides, developments in the field of doped high-voltage spinels focus on process-structure-property relationships and the realisation of full cells. In the case of Li(NixCoyMnz)O2 (NCM) materials, the focus is on re-synthesis with recycled materials.

Materials for post-lithium batteries

The following cathode materials for sodium-ion batteries are being investigated as part of the POLiS Cluster of Excellence:

- Layered oxides

- Polyanionic compounds

- Prussian White analogues

Furthermore, polyanionic battery materials are being developed for potassium-ion batteries.

Materials design

Nanostructured materials are characterised by improved rate capability and cycle stability. Particle coatings are also used to improve stability. Homogeneous coatings are achieved using a chemically activated coating method. For solid-state batteries, in addition to the particle coatings, so-called ‘single crystal’ materials are also important.

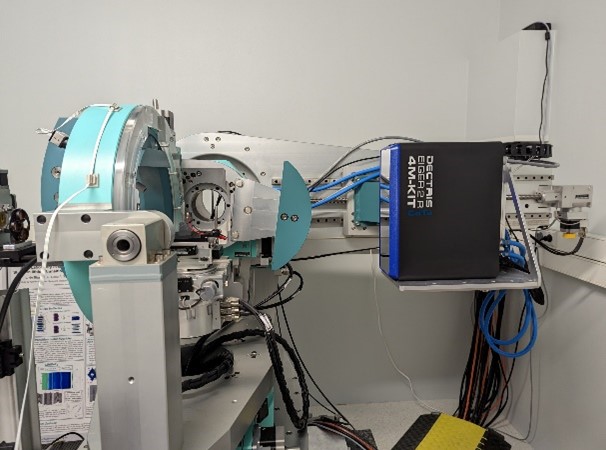

Materials characterization

A flexible laboratory diffractometer with a modern area detector is available for crystallographic characterisation. In addition to operando measurements on coin cells, temperature-dependent XRD experiments are also carried out to optimise synthesis and calcination processes.

Up-scaling of battery materilas (HEMF)

Flexible synthesis facility for the production of battery materials (up to 10 kg). In addition to traditional mixed-oxide methods, precipitation reactions, wet-chemical synthesis as well as particle coatings and pyrolysis reactions can also be conducted.

Image gallery: synthesis facility, agitator bead mill, spray dryers, chamber furnaces with retort, retort furnace, rotary tube furnace.

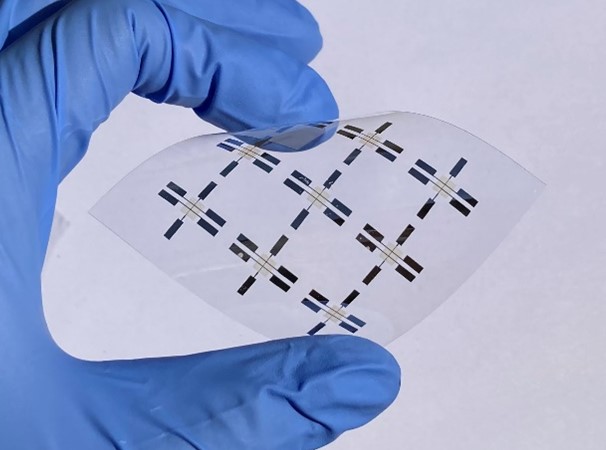

Printed materials

In the field of printed electronics we focus on the development of ceramic inks for the production of passive devices. Inorganic-organic composites combine the excellent dielectric properties of ceramics, e.g. BaxSr1-xTiO3, and the plasticity of polymeric compounds necessary for the printing process on flexible polymer substrates. Multilayer capacitors with high capacity were realized based on polymerizable inks. For varactors, ferroelectric polymers were applied.

Materials for tunable microwave devices

Ceramic materials such as (Ba,Sr)TiO3 need to be optimized for use as tunable microwave components. Strategies to taylor or to modify the dielectric properties of functional materials are doping or the use of dielectric-ferroelectric composite systems. Additives for the reduction of the sintering temperature allow the realization of fully printed microwave devices. The developments were carried out in close cooperation with the IMP at TU Darmstadt.