Cluster of Excellence 3DMM2O

- Ansprechperson:

- Projektgruppe:

Thrust C2

- Förderung:

Deutsche Forschungsgemeinschaft

EXC-2082/1 — 390761711 - Starttermin:

2019

Research

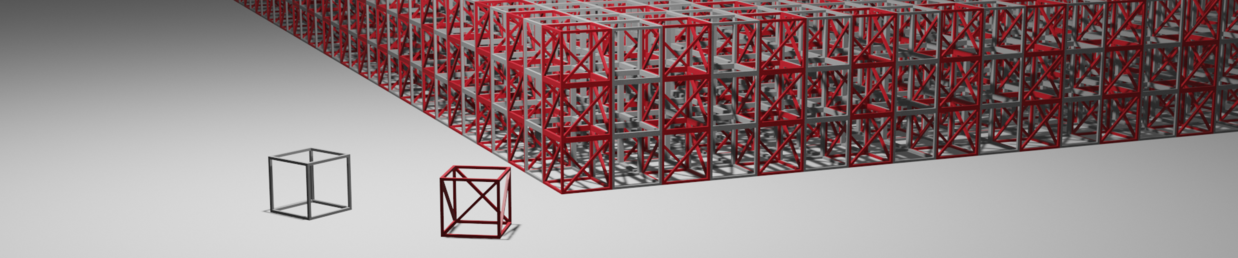

3D Matter Made To Order (3DMM2O) is one of 57 clusters of excellence within Germany’s Excellence Strategy. As a part of this coordinated research effort, our group focuses on the design and the mechanical characterization of three-dimensional (3D) metamaterials. These composite materials derive their mechanical properties from the geometry of their internal structure rather than the properties of the constituent materials. By rationally designing a metamaterials microstructure, unprecedented mechanichal properties, e.g., extraordinary specific strength or unconventional deformation modes, can be achieved. To develop and characterize novel metamaterials, our group combines analytical mechanical approaches, numerical simulations and advanced experimental methods such as high resolution X-ray computed tomography. Current areas of interest include:

-

Biomimetic materials

-

Chiral metamaterials

Biomimetic Materials

Biomimetic research focus in the study of nature hierarchical structures and properties to inspire and develop new materials and engineering solutions. As plants present diverse mechanical features to deal with loads they are subject, they are an interesting case for such studies.

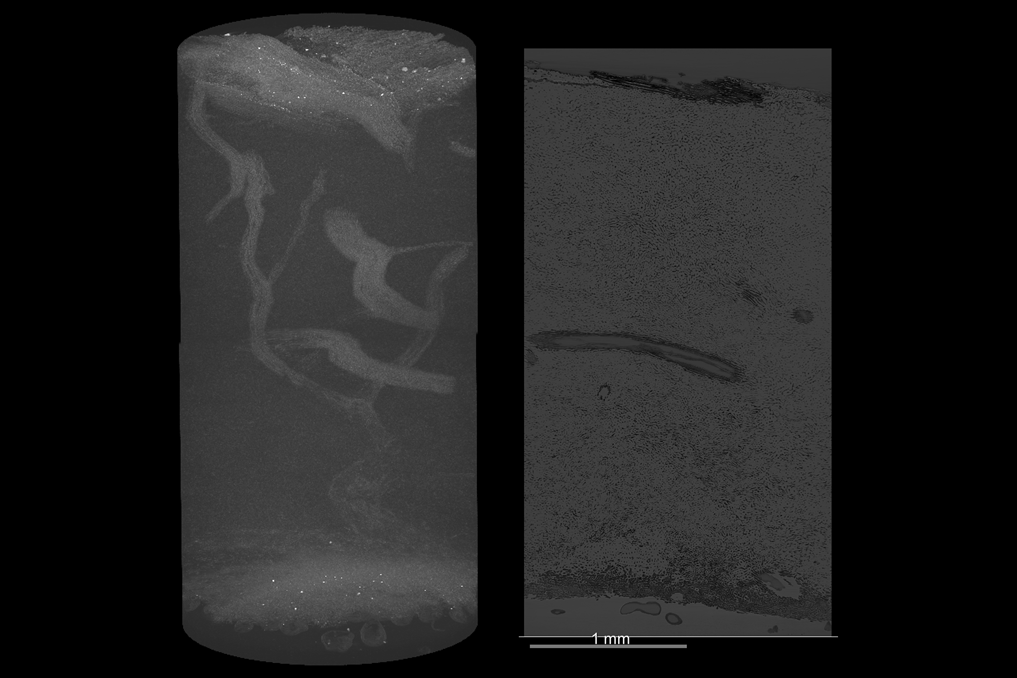

Using micro and nano X-ray computed tomography allows us to visualize the internal details regarding the structure and morphology. Simultaneously in situ mechanical tests can be used to investigate the responsible structures for the mechanical properties of the studied plants.

In our first study, we investigate the coconut endocarp for determination of the toughness responsible structure of such shells.

Chiral Metamaterials

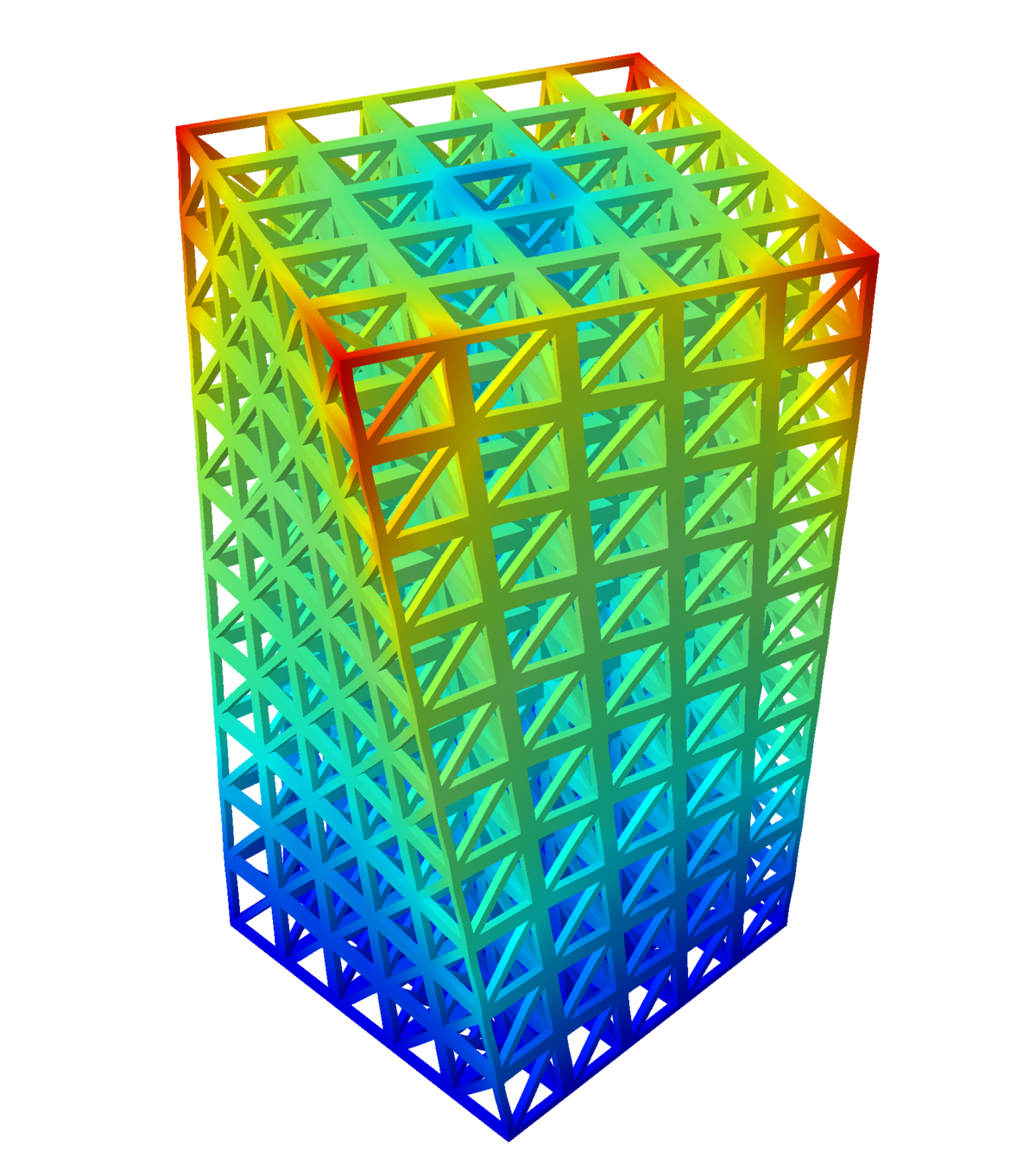

A chiral structure lacks mirror symmetry. As a result, chiral metamaterials can exhibit a twist-to-strain coupling, i.e. they respond with a twisting motion when they are compressed or extended. Such deformation modes are not available in ordinary elastic materials. In fact, they are strictly forbidden by classical “Cauchy” continuum mechanics. Lately, our group has focused on the enhancement of chiral mechanical effects in order to allow for a broader range of applications, e.g., in measurement or actuation devices.

| Name | Titel | Tel. | |

|---|---|---|---|

| Gumbsch, Peter | Prof. Dr. | peter gumbsch ∂does-not-exist.kit edu | +49 721 608-44363 |

| Debastiani, Rafaela | Dr. | rafaela debastiani ∂does-not-exist.kit edu | +49 721 608-26358 |

Publications

Debastiani, R.; Kurpiers, C. M.; Lemma, E. D.; Breitung, B.; Bastmeyer, M.; Schwaiger, R.; Gumbsch, P.

2025. Microscopy Research and Technique, 88 (3), 832–838. doi:10.1002/jemt.24746

Xia, K.; Dong, Z.; Sun, Q.; Debastiani, R.; Liu, S.; Jin, Q.; Li, Y.; Paetzold, U. W.; Gumbsch, P.; Lemmer, U.; Eggeler, Y. M.; Levkin, P. A.; Hernandez-Sosa, G.

2023. Advanced Materials Technologies, 8 (23), Art.Nr.: 2300408. doi:10.1002/admt.202300408

Hussain, N.; Scherer, T.; Das, C.; Heuer, J.; Debastiani, R.; Gumbsch, P.; Aghassi-Hagmann, J.; Hirtz, M.

2022. Small, 18 (42), Article no: 2202987. doi:10.1002/smll.202202987

Frenzel, T.; Hahn, V.; Ziemke, P.; Schneider, J. L. G.; Chen, Y.; Kiefer, P.; Gumbsch, P.; Wegener, M.

2021. Communications materials, 2 (1), Art.Nr. 4. doi:10.1038/s43246-020-00107-w

Findeisen, C.; Forest, S.; Hohe, J.; Gumbsch, P.

2020. Continuum mechanics and thermodynamics, 32 (2), 1629–1645. doi:10.1007/s00161-020-00870-8

Fernandez-Corbaton, I.; Rockstuhl, C.; Ziemke, P.; Gumbsch, P.; Albiez, A.; Schwaiger, R.; Frenzel, T.; Kadic, M.; Wegener, M.

2019. Advanced materials, 31 (26), Art.Nr. 1807742. doi:10.1002/adma.201807742

Ziemke, P.; Frenzel, T.; Wegener, M.; Gumbsch, P.

2019. Extreme mechanics letters, 32, Art:nr. 100553. doi:10.1016/j.eml.2019.100553