Am Lehrstuhl für Werkstoffmechanik wird der Zusammenhang zwischen der Werkstoffmikrostruktur und den damit verbundenen mechanischen Eigenschaften untersucht. Dies geschieht mit Computersimulationen, die es erlauben, experimentell nicht zugängliche Größen und Mechanismen auf verschiedenen Längen- und Zeitskalen zu identifizieren und deren Bedeutung zu quantifizieren. Die Durchführung von Simulationen ermöglicht auch das Einsparen kostspieliger Versuche (z. B. Crash-Tests in der Automobilindustrie) soweit geeignete Materialmodelle und Methoden vorhanden sind. Insbesondere zur Beschreibung von Mikrobauteilen werden neue Methoden entwickelt, da nicht mehr von einer homogenen Mikrostruktur ausgegangen werden kann, wie sie in kontinuumsmechanischen Beschreibungen angenommen wird. Neben Experiment und Theorie hat sich die Computersimulation als dritte Säule in der Werkstoffwissenschaft etabliert.

Die Forschungsaktivitäten erstrecken sich von der mikroskopischen Simulation einzelner Atome bis zur Behandlung makroskopischer Bauteile:

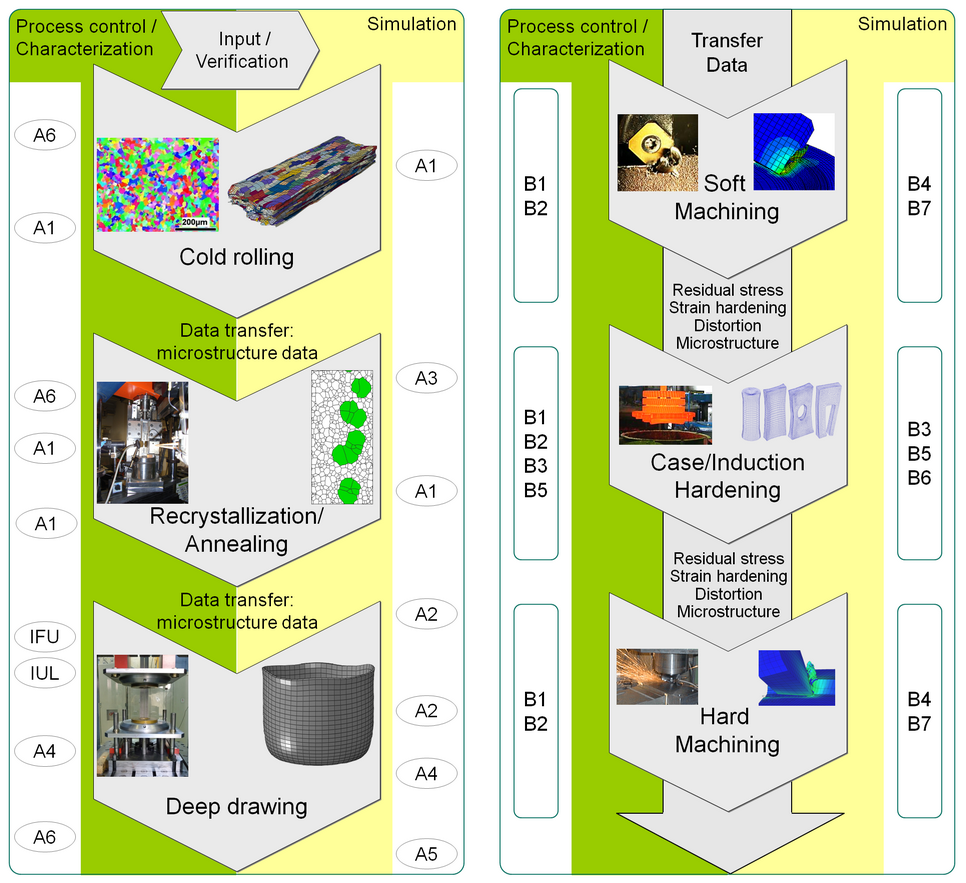

GRK 1483: Process Chains in Production

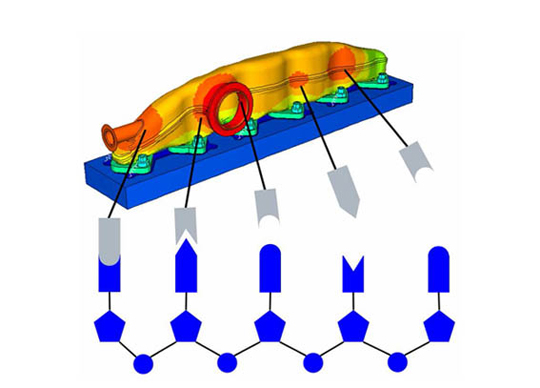

Das Graduiertenkolleg ist im interdisziplinären Forschungs- und Entwicklungsfeld „Computational Engineering – Werkstoffwissenschaft – Produktionstechnik“ angesiedelt. Das Leitthema ist die Prozesskette vom Halbzeug zum Bauteil, deren erstmalige ganzheitliche Betrachtung und prozessübergreifende simulatorische Abbildung die Grenzen des ingenieurwissenschaftlichen Wissens in einer Schlüsseltechnologie verschieben werden. Die Froschungsarbeiten befassen sich mit Prozessketten zur Fertigung von Blechbauteilen aus modernen Stählen (Prozessschritte Walzen, Zwischenglühen, Tiefziehen und Presshärten) und zur Fertigung von Massivbauteilen aus martensitisch härtbaren Stählen (Prozessschritte Weichbearbeitung, Einsatzhärten, Hartbearbeitung und mechanische Oberflächen-behandlung). Sämtliche Arbeiten sind interdisziplinär angelegt und verknüpfen fertigungs-technische Laborversuche, Experimentelle Werkstoff- und Bauteilcharacterisierung, und skalenübergreifende Werkstoff- und Prozesssimulation.

Das Graduiertenkolleg ist im interdisziplinären Forschungs- und Entwicklungsfeld „Computational Engineering – Werkstoffwissenschaft – Produktionstechnik“ angesiedelt. Das Leitthema ist die Prozesskette vom Halbzeug zum Bauteil, deren erstmalige ganzheitliche Betrachtung und prozessübergreifende simulatorische Abbildung die Grenzen des ingenieurwissenschaftlichen Wissens in einer Schlüsseltechnologie verschieben werden. Die Froschungsarbeiten befassen sich mit Prozessketten zur Fertigung von Blechbauteilen aus modernen Stählen (Prozessschritte Walzen, Zwischenglühen, Tiefziehen und Presshärten) und zur Fertigung von Massivbauteilen aus martensitisch härtbaren Stählen (Prozessschritte Weichbearbeitung, Einsatzhärten, Hartbearbeitung und mechanische Oberflächen-behandlung). Sämtliche Arbeiten sind interdisziplinär angelegt und verknüpfen fertigungs-technische Laborversuche, Experimentelle Werkstoff- und Bauteilcharacterisierung, und skalenübergreifende Werkstoff- und Prozesssimulation.

Mikroskopische Skala

| Das mechanische Verhalten von Werkstoffen beruht auf Vorgängen auf atomarer Skala: Defektentstehung, chemische Reaktionen, Phasenumwandlungen ... Die ihnen zugrundeliegenden Mechanismen werden mit atomistischen Methoden untersucht, z.B. mit Molekulardynamik-, Ab-initio- und Hybrid-Methoden. |  |

|

Mesoskopische Skala

| Bei der Simulation physikalischer Prozesse auf der mesoskopischen Längenskala wird das Verhalten von komplexen Gebilden, z.B. von Versetzungen und Korngrenzen, untersucht. Die physikalischen Eigenschaften einzelner Versetzungen oder Korngrenzen gehen in das der Simulation zugrundeliegende Modell ein. Mesoskopische Simulationen ermöglichen es, das kollektive Verhalten von Versetzungen oder Korngrenzen unter vielseitigen Randbedingungen zu untersuchen. |

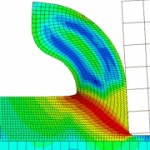

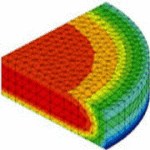

Makroskopische Skala

|

Um makroskopische Systeme zu simulieren, ist es notwendig, das Material als Kontinuum zu modellieren. Die verwendeten Materialmodelle profitieren dabei von den Ergebnissen der mikro- und mesoskopischen Grundlagenforschung. Die entsprechenden Differentialgleichungen werden mit Hilfe der Finite-Elemente-Methode gelöst. |

|

|

Discrete Dislocation Dynamics simulations

Mechanical properties of micro-mechanical components cannot be described properly using classical continuum theories as they show a pronounced size dependency, e.g. in the flow stress. The microstructural length scale, given by the dislocations present in the material, is of the same order of magnitude as the external scale. Therefore, averaging out the length scale of the microstructure, a prerequisite of the classical continuum theories, is no longer applicable. An alternative approach is the Discrete Dislocation Dynamics (DDD) simulation, which allows us to follow the time evolution of a given dislocation microstructure.

Three-dimensional DDD simulations allow modelling of micro structures in single crystalline and poly crystalline samples.

Engineering Mechanics based on Size dependent Materials Properties

When confined to sub-micrometer dimensions, many materials exhibit unexpected and potentially useful properties different from their bulk behaviour. This unusual behaviour can be exploited in small-scale mechanical devices in high-tech industries. Since conventional continuum theory cannot account for size-dependencies, there is a need for new material models complying with both the description of physical effects and the applicability to engineering design. The development of size-dependent continuum theories for both small scale plasticity and fracture mechanics was the central aim of the EU-funded Marie Curie Research Training Network (MC-RTN) SizeDepEn.

pdf

Synchrotron based in situ testing techniques

Nanoscale metallic materials and structures exhibit size-dependent mechanical properties, which deviate substantially from bulk values. Our research aims to quantify these phenomena, with a special view to plastic strength and deformation mechanisms. To access these phenomena, we developed in situ Synchrotron techniques to characterize the evolution of stresses and defects during mechanical testing of metallic thin films and nanostructures. In addition, similar in situ techniques are used to monitor lattice displacements and possible phase transformations during the Li ion intercalation in electrode materials of Li ion batteries.

pdf

Virtual Material Development for High Power Durable Metallisations

The objective of the project HOME (HOchfeste MEtallisierung) is to develop a power durable metallisation for Surface Acoustic Wave (SAW) filters, resistant to high stresses at ultra-high frequencies with a high electric conductivity. The applied methods used bridge the entire range from ab initio modeling to testing. The aim is to understand the mechanisms leading to fatigue and failure, to find physical explanations for a lifetime model and to predict the lifetime depending on the input data such as input power and temperature.

pdf

Identification of Process Specific Size Effects

Understanding process specific size effects is important for down scaling geometries in manufacturing processes. Therefore, the priority program "Modeling of scaling effects on manufacturing processes" (SPP1138) was announced and financed by the "Deutsche Forschungsgemeinschaft". Within this priority program the size effect of the specific cutting force in micro machining was investigated at the izbs by finite element simulation with ABAQUS and a physically based yield law for high strain rates.

pdf

Continuum Theory of Curved Dislocations

Mechanical properties of materials (in particular metals) are strongly influenced by plastic deformation occurring during mechanical straining Carrier of plasticity are dislocations or line-like defects in the ideally perfect crystal. This project aims to predict the complex interaction and evolution of ensembles of dislocations within an (averaged) dislocation-continuum context. Among others, we aim at bridging different length scales in order to predict size effects ('smaller is stronger') for micron-sized devices as well as the plastic flow associated with fluctuation phenomena.

pdf

Microreliability

The research of the group focuses on the relationship of mechanical properties and reliability of materials and their underlying microstructure on the micro- and nanoscale. Of special interest are micro molded component, coating, MEMS and thin film materials as well as bulk nanocrystalline and nanoporous metals.

In addition to the interests in material science, this group addresses challenges in experimental mechanics on this size scale by custom build setups.

pdf

Emmy Noether Group Dynamics of Sliding Metal Surfaces

Sliding surfaces are omnipresent in nature (e.g. in human knee and hip joints), as well as in technical components of all sizes ranging from Micro-Molecular dynamics (MD) Electro-Mechanical systems (MEMS) up to several story high ship engines. During the tribological process metallic surfaces are subjected to complex dynamical changes. The main objective of this group is to observe these nanoscale changes in a multi-contact situation and link topography changes to the frictional response and material removal of the sliding bodies.

pdf

Plasticity in nc Metals and Alloys Molecular dynamics simulations

Project 2: Molecular dynamics simulations of deformation of nanocrystalline palladium

Atomistic simulation of the tensile deformation of 3D nanocrystalline Pd samples at constant strain rate and room temperature is presented. Detailed analysis of the deformation mechanisms was performed.

pdf

Phase field modelling for Ferroelectric Materials

The scope of the BMBF project COMFEM is the development of a knowledge-based multi-scale modelling chain for ferroelectric lead-zirconium-titanate-materials that covers several orders of magnitude in length and time scale. To close the gap between predictive ab initio methods and micromechanics within this simulation chain, thermodynamically motivated phase-field simulations are applied to reproduce the self-organisation of the domain structure.

pdf

Silicon Nitride based Ceramic Wire Rolling Tools

Ceramic-based materials are gaining technological and economical importance in the field of metalforming. Nonetheless, producing tools with high durability and narrow dimensional tolerances is still rudimentary. To fully understand the functionality and furthermore, be able to predict lifetime and durability of silicon nitride based wire-rolling tools, an elaborate damage model has to be established.

pdf

Structure and Failure of Metallic Interfaces in Microelectronic Devices

Heterophase interfaces between fcc and bcc metals exist in many microelectronic devices and in composite materials. Compared to other interphase boundaries, the failure processes at fcc/bcc heterophase boundaries are poorly understood. In this project we study the structure, the mechanical properties and the resistance to damage formation of different fcc/bcc interfaces in the Cu-Ta model system.

pdf

Modeling Plasticity and Dislocation Dynamics of Fusion Relevant Materials

The development of physical based modelling tools for the prediction of the mechanical properties of materials for fusion reactor applications, such as EUROFER or tungsten under irradiation conditions, requires a multiscale approach: MD (molecular dynamics) simulations are used for the description (i) of the structure and energetic landscape of the screw dislocations and (ii) of the interaction with point and other defects.

Discrete Dislocation Dynamics (DDD) simulation in body centered cubic (bcc) has to incorporate the properties of dislocation in bcc obtained by MD to simulate the collective behavior of the dislocations in the presence of irradiation defects.

The understanding of grain growth in polycrystalline materials is one of the oldest and most investigated problems in physical metallurgy. Since the microstructural evolution of metallic and ceramic materials has a huge impact on their mechanical, thermical and electrical properties, it is of outstanding interest to be able to predict the collective behaviour of grain boundaries during grain growth. In this project, we develop a three dimensional vertex dynamics model for grain growth, which is able to handle misorientation and inclination dependent grain boundary energies, mobilities and triple line drag.

pdf

Plasticity in nc Metals and Alloys Deformation mechanisms using snchrotron radiation

DFG Forschergruppe714, Project 5

Nanocrystalline metals show enhanced yield strength. This project focuses on palladium thin films. The characteristic smooth transition between elastic and plastic deformation behaviour suggests microplastic activity in the transition region. Stress-strain curves from tensile tests are recorded during insitu synchrotron X-ray diffraction (XRD). Typically some reversible XRD reflex broadening is observed during the tests, which can be filtered for fingerprints from dislocation or twinning activity.

pdf