Prof. Dr. Christian Greiner

Group Leader

Full Profile

Tel.: +49 721 608-26407

Fax: +49 721 608-24567

Email: greiner∂kit edu

IAM-CMS, KIT

Gebäude 30.48 (MZE)

Strasse am Forum 7

76131 Karlsruhe

Research

The group focuses on materials science aspects of materials under a tribological load.

Our main research topics are:

- The elementary mechanisms for microstructural and chemical changes

- The materials science origins of friction and wear

- Size effects

- Contact mechanics

- Bio-inspired materials and structures

- Laser surface texturing

- Data Science in tribology

- We develop and build our own equipment and instrumentation, e.g. an extremely high resolution in situ reciprocating tribometer

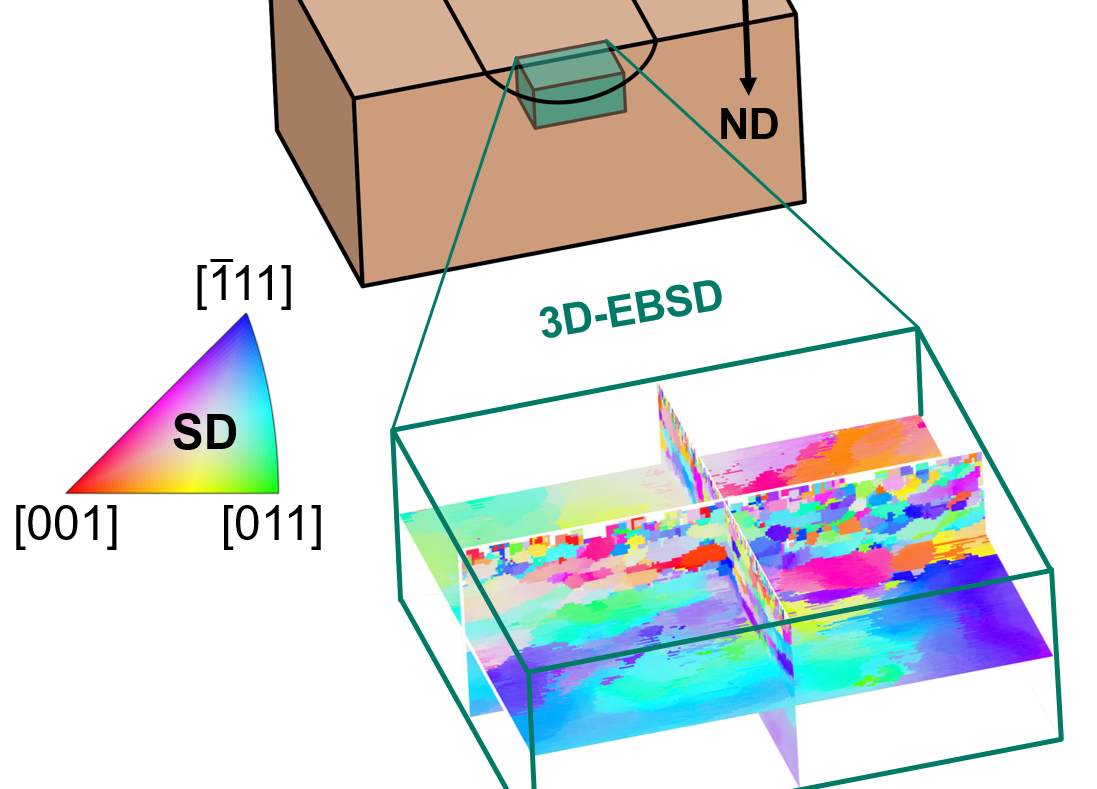

- Make use of ultra-high resolution electron and ion microscopy, including 3D reconstruction techniques

- Morphologically texture surfaces by means of laser radiation

- Employ modern x-ray techniques, including from synchrotron sources

- Collaborate with scientists on an international basis

With this unique combination of scientific expertise and analytical tools we aim at strategically tayloring materials and microstructures for lower friction and less wear.

We always have very attractive topics available for bachelor and master theses, so please do contact us in case you are interested in joining the group!

Tribometry

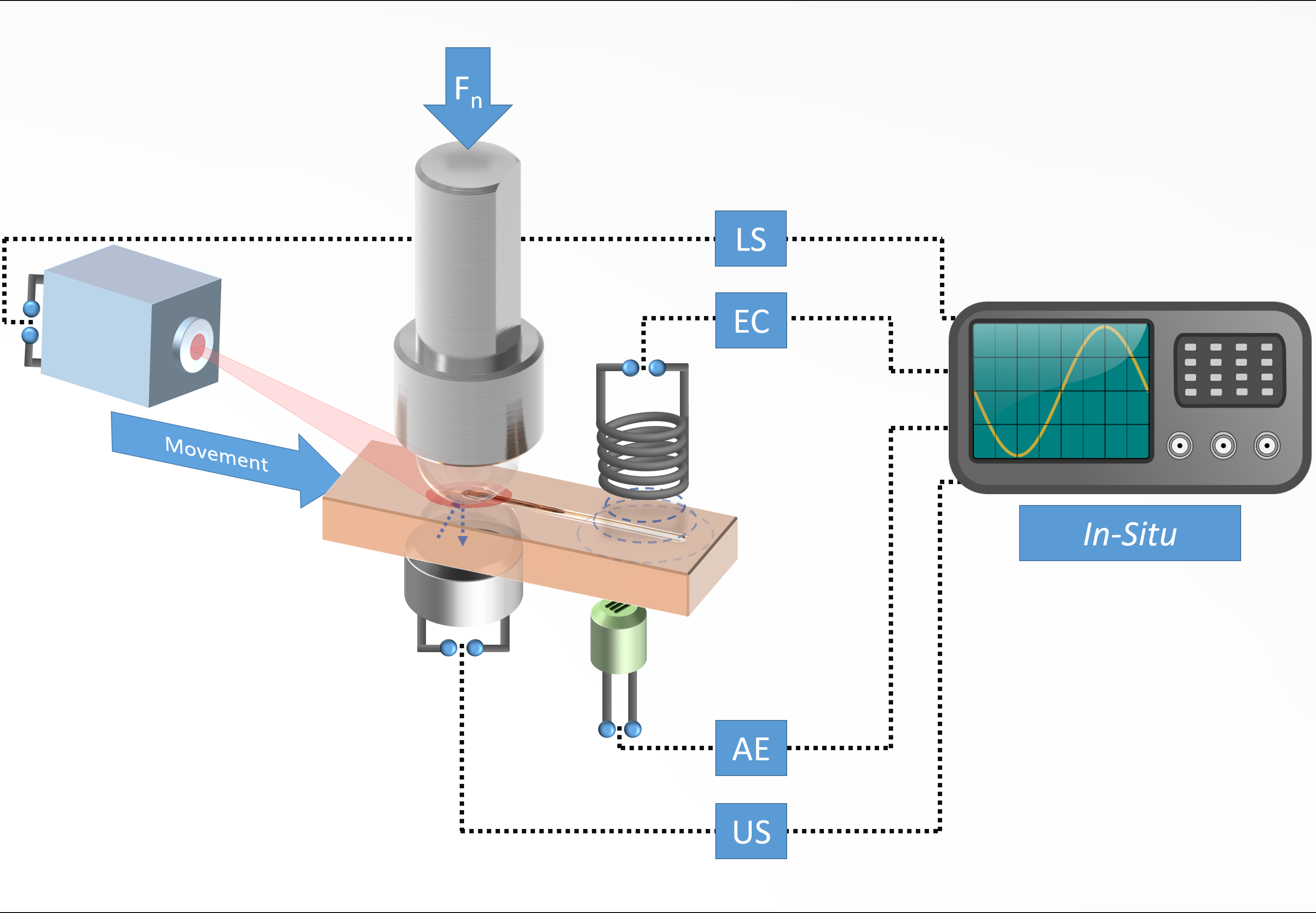

Developing multimodal in-situ tribometry: a core activity in the ERC Starting Grant project TriboKey

Developing multimodal in-situ tribometry: a core activity in the ERC Starting Grant project TriboKey

Tribo-oxidation

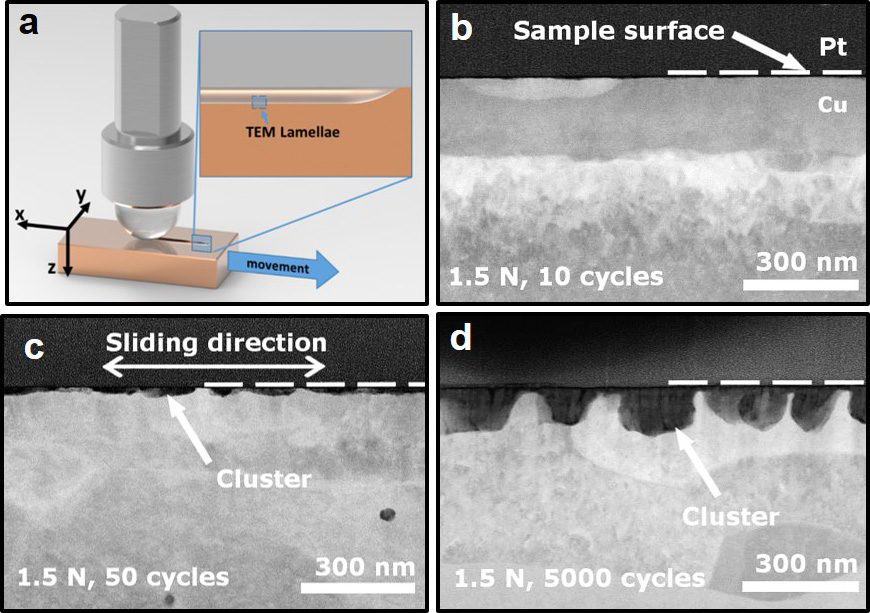

Copper oxide formation under tribological loading. (a) TEM lamellae extraction from sliding track (b-d) Cross-sectional HAADF-STEM images (from TEM lamellae) at varius stages of the sliding sequence.

Copper oxide formation under tribological loading. (a) TEM lamellae extraction from sliding track (b-d) Cross-sectional HAADF-STEM images (from TEM lamellae) at varius stages of the sliding sequence.

| Portrait | Name | Focus | Tel. | |

|---|---|---|---|---|

| Dollmann, Antje PostDoc |

Microstructural Evolution of High-entropy Alloys under Tribological Load | antje dollmann ∂does-not-exist.kit edu | +49 721 204 327-38 | |

| Kisch, Ines PhD Candidate |

Elementary Mechanisms of Tribo-oxidation in Copper | ines blatter ∂does-not-exist.kit edu | +49 721 204 327 46 | |

| 1 additional person visible within KIT only. | ||||

Alumni

| Name | Focus Area |

| Matz, Patrick, | |

| Merkle, Lena, B.Sc. | |

| Bieber, Beatrix, | |

| Sutschet, Susanne, B.Sc. | |

| Chen, Xiang, Postdoc | |

| Becker, Sarah, Ph.D. | |

| Liu, Zhilong, Ph.D. | |

| Popp, Uwe, | |

| Braun, Daniel, Ph.D. | |

| Messer, Philipp, | |

| Schneider, Stefan, | |

| Welter, Vasco, | |

| Schäfer, Michael, | |

| del Gardo, Thais, | |

| Wettich, Helene, | |

| Schmidt, Oliver, M.Sc. | |

| Gorenflo, Max, M.Sc. | |

| Ruebeling, Frederike, Ph.D. |

| Name | Focus Area |

| Schweiger, Max, | |

| Mersch, Simon, | |

| Laube, Stephan, M.Sc. | |

| Günther, Elisabeth, | |

| Heinrich, Julius, M.Sc. | |

| Kurpiers, Chantal, M.Sc. | |

| Salgando, Leonardo, | |

| Merz, Tobias, | |

| Wolff, Karsten, | |

| Lahane, Pratik, | |

| Okle, Philipp, | |

| Otero, Ruben, | |

| Eberle, Valerie, | |

| Roskosch, Thomas, | |

| Aeenehvand, Fatemeh, | |

| Franziska, Meyer, M.Sc. | |

| Schreiber, Paul, Postdoc |

| Titel | Betreuung |

|---|---|

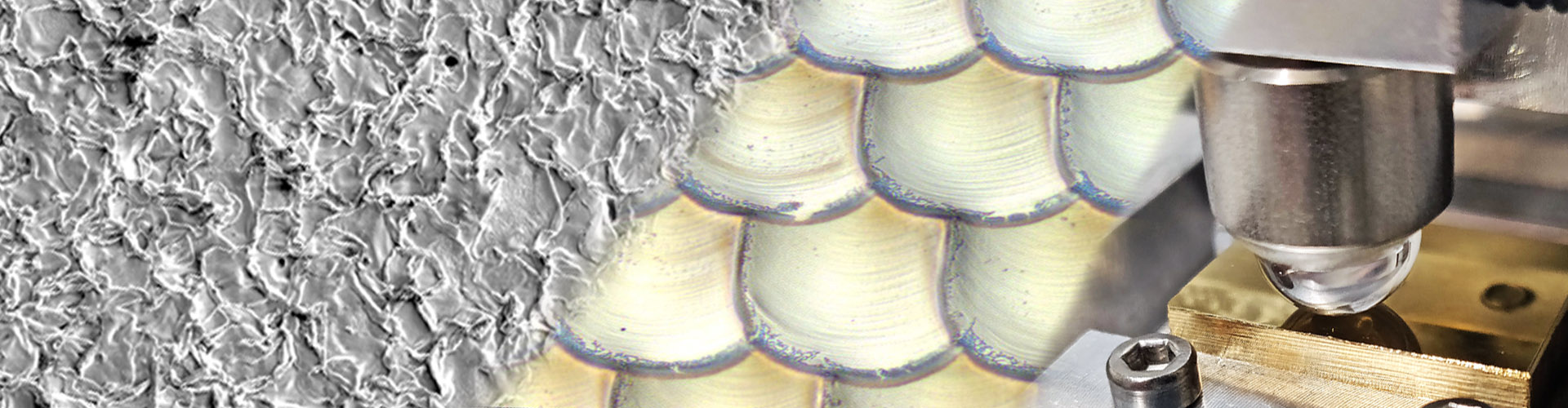

| Bioinspired laser texturing of tribological surfaces | , , |

| Communication Interfaces between Scientists, Machines, and Databases for Data-Centric Machine Learning |

Publications

Apolinario, R. C.; Rêgo, G. C.; Rodrigues, A. M.; David da Silva, D.; Ospina Ramirez, C. A.; Zhou, Q.; Greiner, C.; Moreto, J. A.; Pinto, H. C.

2025. Materials Chemistry and Physics, 335, 130496. doi:10.1016/j.matchemphys.2025.130496

Li, Y.; Zhang, Q.; Liang, F.; Zhang, Y.; Liu, W.; Zhao, Y.; Zhu, Y.; Greiner, C.; Gumbsch, P.; Chen, X.

2024. Acta Materialia, 271, 119888. doi:10.1016/j.actamat.2024.119888

Yue, H.; Vaitkunaite, G.; Li, Y.; Schneider, J.; Greiner, C.; Gumbsch, P.

2023. Tribologie und Schmierungstechnik, 70 (eOnly Son…rausgabe 2), 4–8. doi:10.24053/TuS-2023-0040

Zhou, Q.; Jiao, Z.; Huang, Z.; Shi, Y.; Li, Y.; Yin, C.; Wang, H.; Pinto, H. C.; Greiner, C.; Liu, W.

2024. Acta Materialia, 279, 120299. doi:10.1016/j.actamat.2024.120299

Dollmann, A.; Kübel, C.; Tavakkoli, V.; Eder, S. J.; Feuerbacher, M.; Liening, T.; Kauffmann, A.; Rau, J.; Greiner, C.

2023. doi:10.48550/arXiv.2309.02101

Pereira, J. N.; Ott, V.; Afonso, C. R. M.; de Sousa Malafaia, A. M.; Stüber, M.; Greiner, C.; Pinto, H. C.

2024. Surface and Coatings Technology, 477, Art.-Nr.: 130369. doi:10.1016/j.surfcoat.2023.130369

Dollmann, A.; Kübel, C.; Tavakkoli, V.; Eder, S. J.; Feuerbacher, M.; Liening, T.; Kauffmann, A.; Rau, J.; Greiner, C.

2024. Communications Materials, 5 (1), Art.-Nr.: 4. doi:10.1038/s43246-023-00442-8

Zhang, Q.; Li, Y.; Liang, F.; Zhou, Z.; Li, Y.; Rau, J.; Greiner, C.; Zhao, Y.; Zhu, Y.; Chen, X.

2024. Materials Characterization, 208, 113644. doi:10.1016/j.matchar.2024.113644

Ren, Y.; Zhou, Q.; Hua, D.; Huang, Z.; Li, Y.; Jia, Q.; Gumbsch, P.; Greiner, C.; Wang, H.; Liu, W.

2024. Science Bulletin, 69 (2), 227–236. doi:10.1016/j.scib.2023.12.003

Garabedian, N.; Bagov, I.; Flachmann, M.; Ye, N.; Meller, M.; Bresser, F.; Greiner, C.

2023. SEMPDS 2023: Posters and Demos at SEMANTiCS 2023 - 19th International Conference on Semantic Systems (SEMANTICS), Leipzig, 20th-22nd September 2023, 5 S., CEUR-WS

Kauffmann, A.; Laube, S.; Schellert, S.; Seils, S.; Tirunilai, A. S.; Greiner, C.; Eggeler, Y.; Gorr, B.; Christ, H.-J.; Heilmaier, M.

2023. International Conference on Processing & Manufacturing of Advanced Materials : Processing, Fabrication, Properties, Applications (Thermec 2023), Vienna, Austria, July 2–7, 2023

Li, Y.; Garabedian, N.; Schneider, J.; Greiner, C.

2023. Tribology Letters, 71 (2), Art.-Nr.: 64. doi:10.1007/s11249-023-01736-1

Flachmann, M.; Biesinger, J.; Gorenflo, M.; Bagov, I.; Greiner, C.; Garabedian, N.

2023, May 19. doi:10.5445/IR/1000158825

Li, Y.; Greiner, C.

2023, May 30. doi:10.5445/IR/1000158641

Dollmann, A.; Rau, J. S.; Bieber, B.; Mantha, L.; Kübel, C.; Kauffmann, A.; Tirunilai, A. S.; Heilmaier, M.; Greiner, C.

2023. Scripta Materialia, 229, Art.-Nr.: 115378. doi:10.1016/j.scriptamat.2023.115378

Garabedian, N. T.; Bagov, I.; Weber, K.; Greiner, C.; Bock, F.; Klusemann, B.; Eschke, C.; Wieland, F.; Held, M.

2022. 1st Helmholtz Metadata Collaboration Konferenz 2023 (HMC 2022), Online, October 5–6, 2022. doi:10.5281/zenodo.7125644

Chen, H.; Cai, T.; Ruan, X.; Jiao, C.; Xia, J.; Wei, X.; Wang, Y.; Gong, P.; Li, H.; Atkin, R.; Yin, G.; Zhou, X.; Nishimura, K.; Rosenkranz, A.; Greiner, C.; Wang, B.; Yu, J.; Jiang, N.

2022. ACS Applied Materials and Interfaces, 14 (42), 48091–48105. doi:10.1021/acsami.2c12552

Laube, S.; Kauffmann, A.; Schellert, S.; Seils, S.; Tirunilai, A. S.; Greiner, C.; Eggeler, Y. M.; Gorr, B.; Christ, H.-J.; Heilmaier, M.

2022. Science and Technology of Advanced Materials, 23 (1), 692–706. doi:10.1080/14686996.2022.2132118

Mader, M.; Prediger, R.; Schell, K. G.; Schmidt, G.; Dorn, A.; Dorn, A.; Jenne, S.; Kluck, S.; Hambitzer, L.; Luitz, M.; Luitz, M.; Schwarz, C.; Milich, M.; Greiner, C.

2022. Advanced Science, 9 (31), Art.Nr. 2204385. doi:10.1002/advs.202204385

Dollmann, A.; Kauffmann, A.; Heilmaier, M.; Srinivasan Tirunilai, A.; Mantha, L. S.; Kübel, C.; Eder, S. J.; Schneider, J.; Greiner, C.

2022. Journal of Materials Science, 57, 17448–17461. doi:10.1007/s10853-022-07661-3

Kluck, S.; Hambitzer, L.; Luitz, M.; Mader, M.; Sanjaya, M.; Balster, A.; Milich, M.; Greiner, C.; Kotz-Helmer, F.; Rapp, B. E.

2022. Nature Communications, 13 (1), Art.-Nr.: 5048. doi:10.1038/s41467-022-32767-2

Li, Y.; Schreiber, P.; Schneider, J.; Greiner, C.

2022. Friction, 11 (6), 1079–1093. doi:10.1007/s40544-022-0654-1

de Castilho, B. C. N. M.; de Sousa Mazuco, F.; Rodrigues, A. M.; Avila, P. R. T.; Apolinario, R. C.; Daum, P.; da Costa, F. P.; Menezes, R. R.; de Araújo Neves, G.; Greiner, C.; Pinto, H. C.

2022. Nanomaterials, 12 (14), Art.-Nr.: 2465. doi:10.3390/nano12142465

Xu, Y.; Balint, D. S.; Greiner, C.; Dini, D.

2022. doi:10.48550/arXiv.2203.08886

Xu, Y.; Balint, D. S.; Greiner, C.; Dini, D.

2022. Friction, 11 (3), 473–488. doi:10.1007/s40544-022-0624-7

Apolinario, R. C.; Rodrigues, A. M.; Avila, P. R. T.; Pereira, J. N.; Ramirez, C. A. O.; Daum, P.; Costa, F. P. da; Lira, H. de L.; Neves, G. de A.; Greiner, C.; Pinto, H. C.

2022. Nanomaterials, 12 (14), Art.Nr.: 2410. doi:10.3390/nano12142410

Ren, Y.; Jia, Q.; Du, Y.; Zhou, Q.; Greiner, C.; Hua, K.; Wang, H.; Wang, J.

2022. Friction, 10 (10), 1722–1738. doi:10.1007/s40544-022-0606-9

Garabedian, N. T.; Schreiber, P. J.; Brandt, N.; Zschumme, P.; Blatter, I. L.; Dollmann, A.; Haug, C.; Kümmel, D.; Li, Y.; Meyer, F.; Morstein, C. E.; Rau, J. S.; Weber, M.; Schneider, J.; Gumbsch, P.; Selzer, M.; Greiner, C.

2022. Scientific Data, 9 (1), Art.Nr. 315. doi:10.1038/s41597-022-01429-9

Rau, J. S.; Schmidt, O.; Schneider, R.; Debastiani, R.; Greiner, C.

2022. Advanced Engineering Materials, 24 (11), Art.Nr. 2200518. doi:10.1002/adem.202200518

Tsybenko, H.; Tian, C.; Rau, J.; Breitbach, B.; Schreiber, P.; Greiner, C.; Dehm, G.; Brinckmann, S.

2022. Acta Materialia, 227, Art.-Nr.: 117694. doi:10.1016/j.actamat.2022.117694

Brandt, N.; Garabedian, N. T.; Schoof, E.; Schreiber, P. J.; Zschumme, P.; Greiner, C.; Selzer, M.

2022. Data, 7 (2), Art.-Nr. 15. doi:10.3390/data7020015

Mader, M.; Hambitzer, L.; Schlautmann, P.; Jenne, S.; Greiner, C.; Hirth, F.; Helmer, D.; Kotz-Helmer, F.; Rapp, B. E.

2021. Advanced Science, 8 (23), Art.-Nr. 2103180. doi:10.1002/advs.202103180

Rau, J. S.; Balachandran, S.; Schneider, R.; Gumbsch, P.; Gault, B.; Greiner, C.

2021. Acta Materialia, 221, Art.-Nr.: 117353. doi:10.1016/j.actamat.2021.117353

Rau, J.; Schmidt, O.; Schneider, R.; Greiner, C.

2021, October 18. doi:10.5445/IR/1000138897

Linsler, D.; Ruebeling, F.; Greiner, C.

2021. Metals, 11 (8), 1258. doi:10.3390/met11081258

Mattheck, C.; Greiner, C.; Bethge, K.; Tesari, I.; Weber, K.

2021. Materials, 14 (14), Art.-Nr. 3894. doi:10.3390/ma14143894

Guenther, E.; Kahlert, M.; Vollmer, M.; Niendorf, T.; Greiner, C.

2021. Materials, 14 (4), 928. doi:10.3390/ma14040928

Xu, Y.; Ruebeling, F.; Balint, D.; Greiner, C.; Dini, D.

2021. International Journal of Plasticity, 138, Article no: 102942. doi:10.1016/j.ijplas.2021.102942

Greiner, C.; Günther, E.

2021, February 18. doi:10.5445/IR/1000129689

Lehmann, J.; Schmidt, O.; Schneider, R.; Greiner, C.

2020, September 24. Materials Science and Engineering Congress (MSE 2020), Online, September 22–25, 2020

Seitz, M.; Dürrschnabel, M.; Kauffmann, A.; Kurpiers, C.; Greiner, C.; Weidenmann, K. A.

2021. Advanced engineering materials, 23 (2), Art.Nr. 2000575. doi:10.1002/adem.202000575

Lutz, C.; Bog, U.; Thelen, R.; Syurik, J.; Malik, S.; Greiner, C.; Hölscher, H.; Hirtz, M.

2020. ACS applied nano materials, 3 (8), 7899–7907. doi:10.1021/acsanm.0c01374

Liu, Z.; Messer-Hannemann, P.; Laube, S.; Greiner, C.

2020. Friction, 8, 1117–1136. doi:10.1007/s40544-019-0345-8

Dollmann, A.; Kauffmann, A.; Heilmaier, M.; Haug, C.; Greiner, C.

2020. Journal of materials science, 55 (26), 12353–12372. doi:10.1007/s10853-020-04806-0

Lehmann, J.; Schneider, R.; Greiner, C.

2020, March 23. doi:10.5445/IR/1000117786

Lehmann, J.; Greiner, C.; Schneider, R.

2020, January 30. 22nd International Colloquium Tribology (2020), Ostfildern, Germany, January 28–30, 2020

Laube, S.; Kauffmann, A.; Ruebeling, F.; Freudenberger, J.; Heilmaier, M.; Greiner, C.

2020. Acta materialia, 185, 300–308. doi:10.1016/j.actamat.2019.12.005

Lehmann, J.; Schneider, R.; Greiner, C.

2019, September 4. 46th Leeds-Lyon Symposium on Tribology (2019), Lyon, France, September 2–4, 2019

Greiner, C.; Gagel, J.; Gumbsch, P.

2019. Advanced materials, 31 (26), Art.Nr.: 1806705. doi:10.1002/adma.201806705

Lui, Z.; Lehmann, J.; Patzig, C.; Selle, S.; Höche, T.; Gumbsch, P.; Greiner, C.

2018, June 27. Gordon Research Conference on Tribology - Progress in Tribology at the Interface Between Disciplines (GRC 2018), Lewiston, ME, USA, June 24–29, 2018

Lui, Z.; Lehmann, J.; Patzig, C.; Selle, S.; Höche, T.; Gumbsch, P.; Greiner, C.

2018, September 27. Materials Science and Engineering Congress (MSE 2018), Darmstadt, Germany, September 26–28, 2018

Lehmann, J.; Matz, P.; Schäfer, M.; Greiner, C.

2017, May 30. 644. Wilhelm und Else Heraeus Seminar (2017), Bad Honnef, Germany, May 28–31, 2017

Lehmann, J.; Liu, Z.; Gumbsch, P.; Greiner, C.

2019, April 25. Spring Meeting and Exhibit (MRS 2019), Phoenix, AZ, USA, April 22–26, 2019

Liu, Z.; Lehmann, J.; Patzig, C.; Selle, S.; Höche, T.; Gumbsch, P.; Greiner, C.

2018, June 23. Gordon Research Seminar on Tribology - Progress in Tribology at the Interface Between Disciplines (GRS 2018), Lewiston, ME, USA, June 23–24, 2018

Lutz, C.; Bog, U.; Loritz, T.; Syurik, J.; Malik, S.; Kumar, C. N. S.; Kübel, C.; Bruns, M.; Greiner, C.; Hirtz, M.; Hölscher, H.

2019. Small, 15 (7), 1970036. doi:10.1002/smll.201970036

Wu, W.; Yu, S.; Greiner, C.; Gomard, G.; Hölscher, H.

2019. DPG-Frühjahrstagung der Sektion Kondensierte Materie (SKM), Fachverband Oberflächenphysik (2019), Regensburg, Germany, March 31–April 5, 2019

Kotz, F.; Schneider, N.; Striegel, A.; Wolfschläger, A.; Keller, N.; Worgull, M.; Bauer, W.; Schild, D.; Milich, M.; Greiner, C.; Helmer, D.; Rapp, B. E.

2018. Advanced materials, 30 (22), 1707100. doi:10.1002/adma.201707100

Lutz, C.; Bog, U.; Loritz, T.; Syurik, J.; Malik, S.; Kumar, C. N. S.; Kübel, C.; Bruns, M.; Greiner, C.; Hirtz, M.; Hölscher, H.

2019. Small, Article no 1803944. doi:10.1002/smll.201803944

Schneider, J.; Djamiykov, V.; Greiner, C.

2018. Beilstein journal of nanotechnology, 9, 2561–2572. doi:10.3762/bjnano.9.238

Wu, W.; Lutz, C.; Mersch, S.; Thelen, R.; Greiner, C.; Gomard, G.; Hölscher, H.

2018. Beilstein journal of nanotechnology, 9, 2618–2627. doi:10.3762/bjnano.9.243

Chen, X.; Schneider, R.; Gumbsch, P.; Greiner, C.

2018. Acta materialia, 161, 138–149. doi:10.1016/j.actamat.2018.09.016

Kotz, F.; Schneider, N.; Striegel, A.; Wolfschläger, A.; Keller, N.; Worgull, M.; Bauer, W.; Schild, D.; Milich, M.; Greiner, C.; Helmer, D.; Rapp, B. E.

2018. Advanced materials, 30 (22), Art.Nr. 1870151. doi:10.1002/adma.201870151

Liu, Z.; Patzig, C.; Selle, S.; Höche, T.; Gumbsch, P.; Greiner, C.

2018. Scripta materialia, 153, 114–117. doi:10.1016/j.scriptamat.2018.05.008

Greiner, C.; Liu, Z.; Schneider, R.; Pastewka, L.; Gumbsch, P.

2018. Scripta materialia, 153, 63–67. doi:10.1016/j.scriptamat.2018.04.048

Helmer, D.; Keller, N.; Kotz, F.; Stolz, F.; Greiner, C.; Nargang, T. M.; Sachsenheimer, K.; Rapp, B. E.

2017. Scientific reports, 7, Art.Nr. 15078. doi:10.1038/s41598-017-15287-8

Schneider, J.; Braun, D. A.; Greiner, C.

2017. Lubricants, 5 (3), Art. Nr.: 32. doi:10.3390/lubricants5030032

Greiner, C.

2007. Bio-mimetic and Bio-inspired Nanomaterials for Life Sciences, Wiley-VCH Verlag. doi:10.1002/9783527610419.ntls0203

Greiner, C.; Liu, Z.; Strassberger, L.; Gumbsch, P.

2016. ACS applied materials & interfaces, 8 (24), 15809–15819. doi:10.1021/acsami.6b04035

Greiner, C.; Hölscher, H.

2016. Physik in unserer Zeit, 47 (3), 116–122. doi:10.1002/piuz.201601422

Schaefer, M.; Greiner, C.

2015. Bioinspiration & biomimetics, 10 (4), Art.Nr.:044001. doi:10.1088/1748-3190/10/4/044001

Wolff, K.; Liu, Z.; Braun, D.; Schneider, J.; Greiner, C.

2016. Tribology international, 102, 540–545. doi:10.1016/j.triboint.2016.06.016

Kotz, F.; Plewa, K.; Bauer, W.; Schneider, N.; Keller, N.; Nargang, T.; Helmer, D.; Sachsenheimer, K.; Schäfer, M.; Worgull, M.; Greiner, C.; Richter, C.; Rapp, B.

2016. Advanced materials, 28 (23), 4646–4650. doi:10.1002/adma.201506089

Greiner, C.; Merz, T.; Braun, D.; Codrignani, A.; Magagnato, F.

2015. Surface topography, 3 (4). doi:10.1088/2051-672X/3/4/044001

Greiner, C.; Schäfer, M.; Popp, U.; Gumbsch, P.

2014. ACS Applied Materials & Interfaces, 6 (11), 7986–7990. doi:10.1021/am500879m

3D-EBSD: crystallographic orientation in 3D, here within a copper wear track.

3D-EBSD: crystallographic orientation in 3D, here within a copper wear track.