Dr. Dr. Gerda Vaitkunaite

- Postdoctoral Research Fellow

- Postdoc, Tribology

- Room: 317

CS 30.49 - gerda vaitkunaite ∂does-not-exist.kit edu

Focus Areas

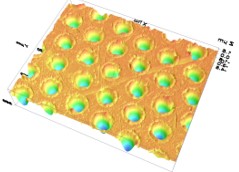

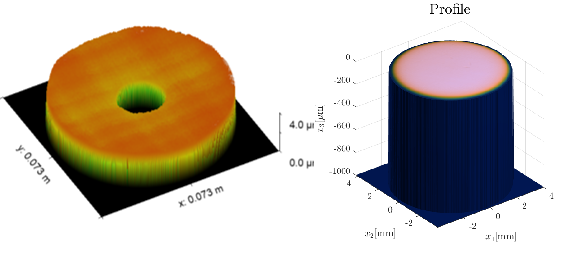

Surface Texturinge

Macrogeometry Characterisation

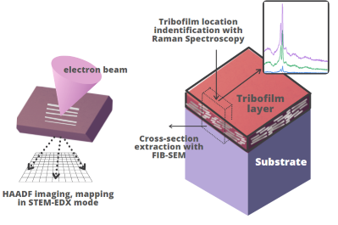

Laser Spectroscopy

About

Gerda’s BEng and MEng projects analysed development of Diamond Like Carbon (DLC) coatings for engine components. In her MEng project, a correlation was established between the deposition process chemistry, coating friction performance and resistance to impact. In 2018 Gerda joined the Institute of Functional Surfaces at the University of Leeds (UK) to work on a PhD supervised by Prof. Ardian Morina, Prof. Anne Neville and industrial advisor Benoit Thiebaut from TotalEnergies (France). During her PhD, Gerda was involved in studying the performance of engine tribological components. In collaboration with industry, the PhD investigated the underlying reactions of lubricant additives with the aim to improve lubricant formulation for passenger cars. Gerda has always been involved in outreach and teaching at the various academic institutions that she has attended. At Leeds she taught courses on fundamentals of Raman Spectroscopy and tribometer testing methodology while supervising and managing laboratory responsibilities. Currently Gerda works in collaborative DFG funded project with Institute of Fluid Mechanics (ISTM). The project aims to improve the understanding of macrogemetry and surface texturing influence on the tribological performance. To achieve this, Gerda is contributing towards development of the digital twin of the experimental tribosystem by providing an experimental characterisation of the tribological response.

She has also been recognised widely for her excellence in approach, receiving multiple awards and scholarships for her academic achievements and research potential. Gerda’s contribution in the fields of tribology, lubrication and wear has been awarded Institute of Mechanical Engineers (United Kingdom, London) Tribology Bronze Medal.

Education

|

University of Leeds (Leeds, UK) |

Ph.D. in Mechanical Engineering,

Advisors: Prof. Ardian Morina, Prof. Anne Neville

Corporate sponsor: TotalEnergies (Lyon, France) |

Awards and Scholarships

| Research Excellence Award, University of Leeds, United Kingdom | 2022 |

| Networking grant for Connecting Young Scientists (ConYS), Karlsruhe House of Young Scientists, Germany | 2022 |

| Tribology Bronze Medal, Institute of Mechanical Engineers (IMechE), London, United Kingdom | 2021 |

| 2018-2021 TOTAL and University of Leeds Scholarship for Doctoral Research | 2018 |

| Vilnius Tech University Rector's Scholarship for Promising Young Researchers | 2017 |

| Most Perspective Graduate Award in Vilnius Tech | 2017 and 2015 |

| Research Council of Lithuania Competitive Research Award for Young Scientists | 2014 |

| 2011-2017 Republic of Lithuania Governmental Scholarship for Higher Education | 2011 |

Taught courses

Supervised Thesis projects

Entwicklung eines Verfahrens zur Lasernachbearbeitung von laserstrukturierten 100Cr6 Stahloberfächen

Entwicklung eines Verfahrens zur Lasernachbearbeitung von laserstrukturierten 100Cr6 Stahloberfächen

Publications

|

G. Vaitkunaite, C. Espejo, B. Thiébaut, A. Neville, A. Morina. (2022) " Low friction tribofilm formation and distribution on an engine cylinder tested with MoDTC-containing low viscosity engine lubricants"; Tribology International Vol. 171. https://doi.org/10.1016/j. |

|

G. Vaitkunaite, C. Espejo, C. Wang, B. Thiébaut, C. Charrin, A. Neville, A. Morina. (2020) "MoS2 Tribofilm Distribution from Low Viscosity Lubricants and its Effect on Friction." Tribology International, Vol. 151 https://doi.org/10.1016/j.triboint.2020.106531. |

|

V. Markowic, Z. Mierzejewska, G. Vaitkunaite, S. Indrisiunas, R. Lukauskaite, O. Cernasejus, V. Golubev. (2016) "Investigation of the Laser Polishing Influence on the Parts Built by SLS." Mechatronic Systems and Materials, 2016. DOI: 10.4028/www.scientific.net/SSP.251.8. |

|

In Preparation or Review G. Vaitkunaite, C. Espejo, C. Wang, B. Thiébaut, A. Neville, A. Morina. MoS2 tribofilm evolution and friction induction studies with Raman Spectroscopy.

|