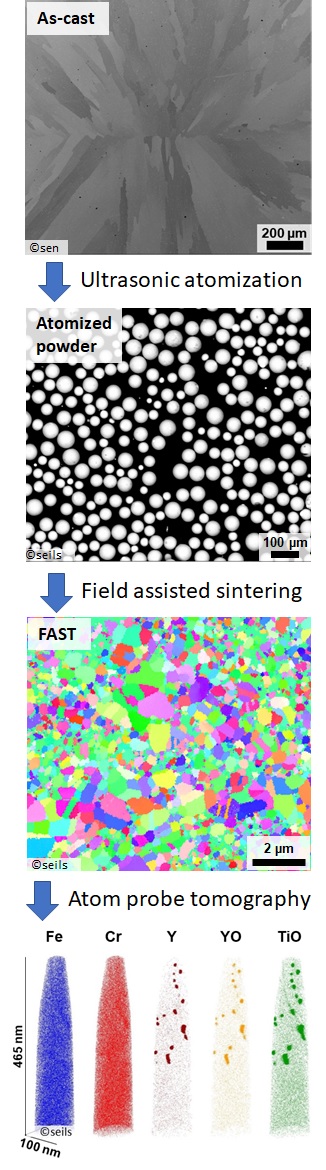

Nanocluster formation in oxide-dispersion strengthened steels by internal oxidation subsequent to ultrasonic powder atomization

Motivation

Conventional high temperature steels are applicable at temperatures up to about 600 °C which restricts the usage of these steels at elevated temperatures. In this regard, scientific interest in the development of ferritic or austenitic oxide dispersed strengthened (ODS) has steadily increased in the past decades. These dispersed oxide particles, known as nano-clusters (NC), with a preferable size of a few nanometers, have been reported to improve a plethora of mechanical properties like room temperature strength, creep resistance at elevated temperatures as well as resistance to radiation induced swelling which could potentially entail the application of these steel in fusion reactors in the future.

In the past, the synthesis of the ODS alloys have been carried out by mechanical alloying (MA) of elemental powders along with powders of oxides such as Y2O3. There are however some problems associated with the production of ODS alloys by MA. The primary problem is the significant contamination by interstitial atoms, specifically by O from the process itself, which leads to the formation of larger and inhomogeneously dispersed oxides in addition to the NCs. These larger oxides are undesirable while designing new alloys. Furthermore, this restricts the investigation of the fundamental mechanisms that lead to the nanocluster formation.

In this project, we study the synthesis of Fe-Cr based ferritic ODS alloys by a new approach. We replace the MA process with ultrasonic atomization of an arc melted alloy which is then sintered to form a solid system. The Y2O3 powder used in the MA process are also replaced by elemental Y while synthesizing the alloy in the arc-melter. This process keeps the quantity of interstitial oxygen impurity level low enough that the formation of the larger oxides (as in the MA process) is prevented but high enough the NCs can be produced though internal oxidation.

Objectives

- Synthesis of an Fe-Cr-Ti-Y based ODS alloy though arc melting process

- Ultrasonic (US) atomization of the arc melted alloy to produce powders

- Investigation of oxygen content in the US generated powder

- Consolidation of these powder using Field Assisted Sintering (FAST)

- Investigation of the nanoclusters formed at the nano level

Investigations

- Characterization of powders morphology (scanning electron microscopy), phase (X-Ray Diffraction) and chemical composition (Hot Carrier Gas Extraction)

- Microstructural characterization of the sintered samples via scanning electron microscopy (SEM) and transmission electron microscopy (TEM)

- Characterization of oxide nano clusters using atom probe tomography (APT)

- Evaluation of microstructural evolution at elevated temperatures and under ion irradiation

Funding

Deutsche Forschungsgemeinschaft