Additive Manufacturing

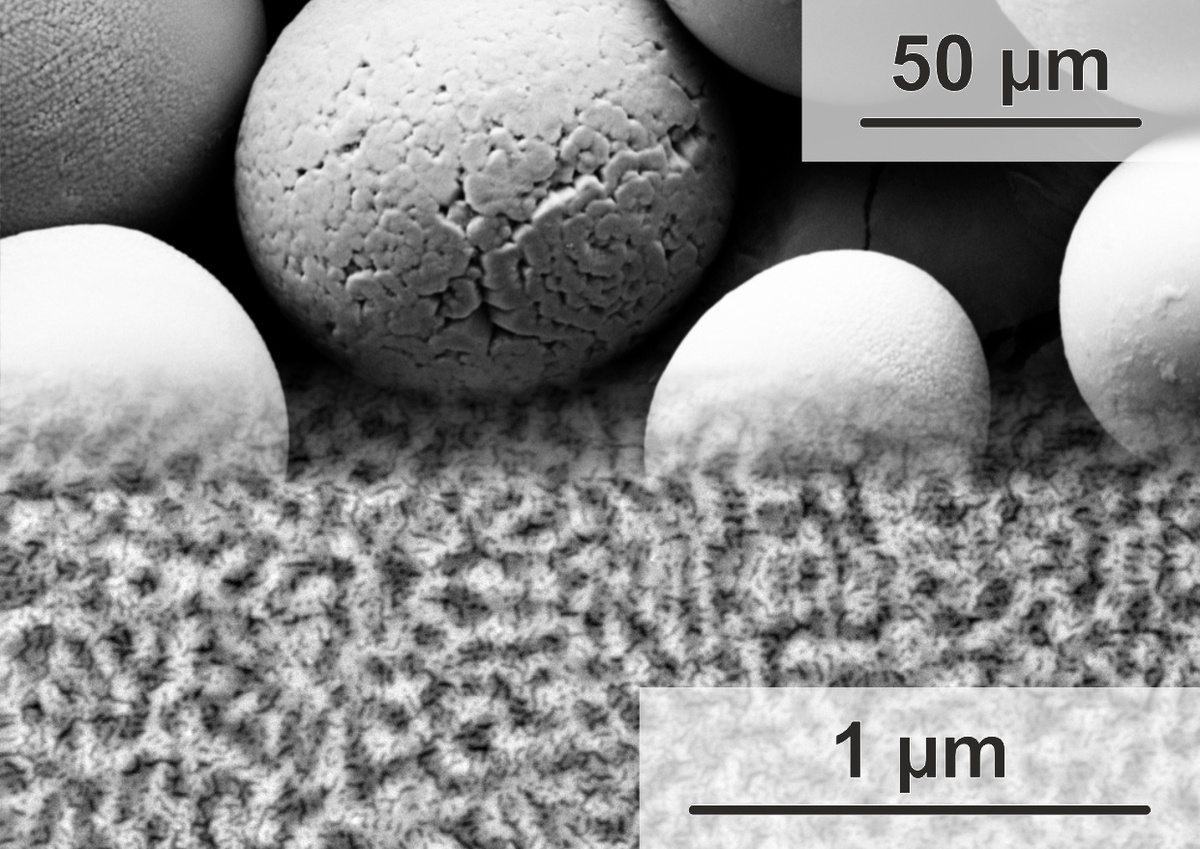

Additive Manufacturing (AM) describes a group of new processing techniques to create complex net-shaped parts. There is no need for conventional processing techniques, like machining, joining, or forging parts. Instead, the component is directly manufactured from CAD modells using powders or wires as starting materials and a laser or electron beam as an energy source. Due to metallurgical characteristics, like high cooling rates, those "3-D printed" parts often feature extraordinary mechanical properties and oxidation resistance. Electron beam melting (EBM) is the most promising AM technique to fabricate components from new refractory based high-temperature materials for applications above 1200°C. EBM is one of the two powder bed-based processes for metals. Compared to the other one, which is called selective laser melting (SLM), EBM offers a high pre-heating temperature, which improves the processability of refractory-based materials. With our current research topics, we aim to understand the correlation between processing parameters, microstructure, mechanical, and oxidation properties of EBM manufactured alloys.

Currently, we are working on following topics using Additive Manufacturing:

- M.Sc. Gabriely Falcão:

Powder Synthesis and Fundamental Properties of Mo-Ti-Si Alloys for Additive Manufacturing and Development of Oxidation-Resistant Cr-Mo-Si Alloys - Dr.-Ing. Daniel Schliephake:

Novel eutectic and high-melting-point Mo-Si-Ti alloys manufactured by Additive Manufacturing: microstructure, texture, and induced properties - Dr. Sandipan Sen:

Holistic qualification of copper for the binder jetting process with targeted porosity adjustment based on heat exchangers for electromobility