Novel eutectic and high-melting-point Mo-Si-Ti alloys manufactured by Additive Manufacturing: microstructure, texture, and induced properties

Motivation

Mo-based silicides have been investigated as potential high temperature materials for more than 20 years due to their excellent mechanical properties. The addition of boron not only improves the mechanical properties but also the oxidation behavior at elevated temperatures.

However, a major problem is the so-called "pest" phenomenon that occurs with refractory metals. In this case, volatile oxides are often formed at temperatures below the service temperature, which can cause the material to disintegrate. Mo-Si-Ti alloys with a high proportion of eutectic microstructure are the only Mo-based silicides known to be oxidation resistant even in the usual pesting range.

Another problem with Mo-based silicides is their often high brittle-ductile-transition-temperature (BDTT), which complicates the fabrication and machining of components made from these alloys. First successfully fabricated samples of a Mo-Si-Ti alloy by laser metal deposition (LMD) by our collaborators, Christopher Zink and Florian Galgon at FAU, show that the BDTT is not too critical. Our preliminary investigations on microstructure and mechanical properties show a dependence of the deposition direction by LMD. These first results should be transferred to other additive manufacturing processes in the future.

Objectives

- Identify other suitable additive manufacturing processes besides LMD

- Development of suitable process parameters for the production of simple geometries for subsequent characterization

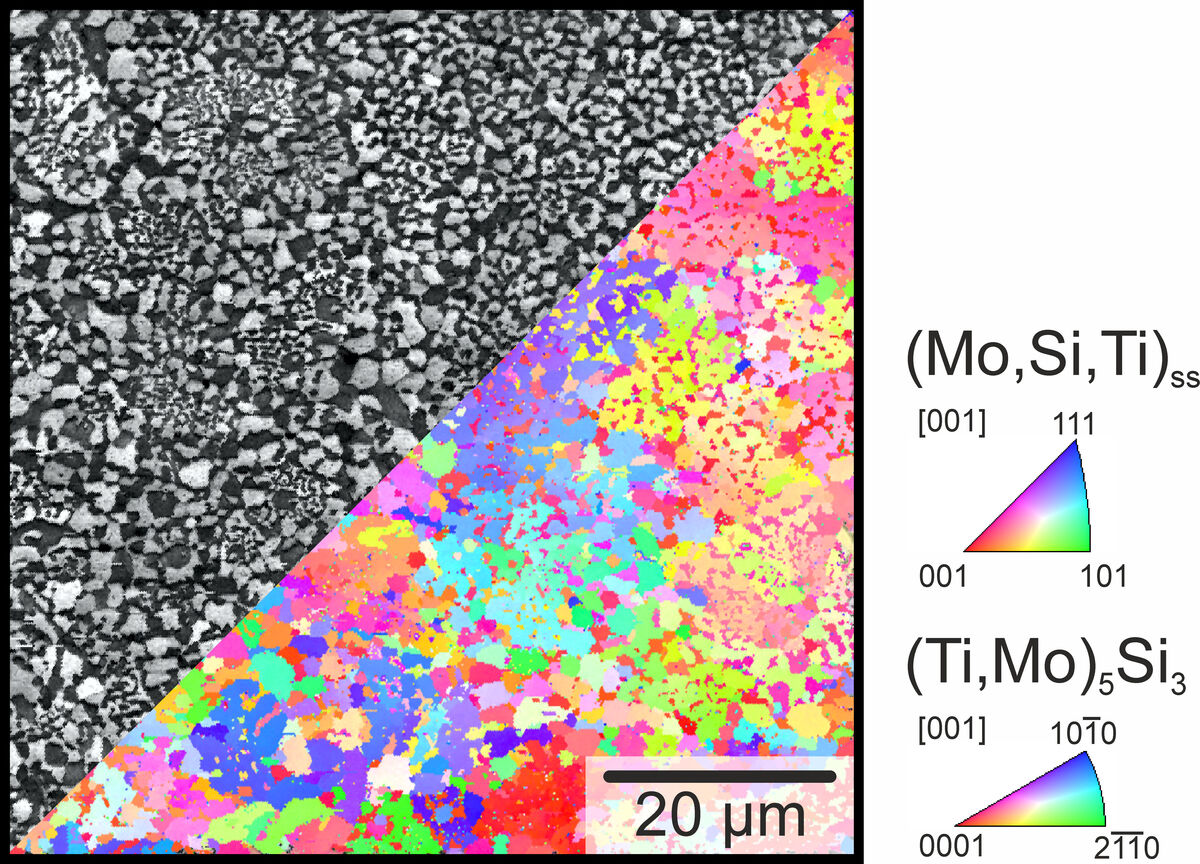

- Determine the influence of process parameters on microstructure and texture of Mo-Si-Ti alloys

- Characterization of mechanical properties at elevated temperatures (up to 1200°C)

- Characterization of oxidation behavior in the pest region and at potential service temperatures

- Correlation between process parameters, microstructure and properties

Investigations

- Parameter study for the production of non-porous samples

- Microstructure characterization and high-temperature microstructure stability

- Chemical elemental analysis to evaluate the manufacturing route

- Determination of mechanical properties in flexure, compression and tension

Funding

Deutsche Forschungsgemeinschaft