Development of novel Ti-based alloys with improved thermal-mechanical capability

Motivation

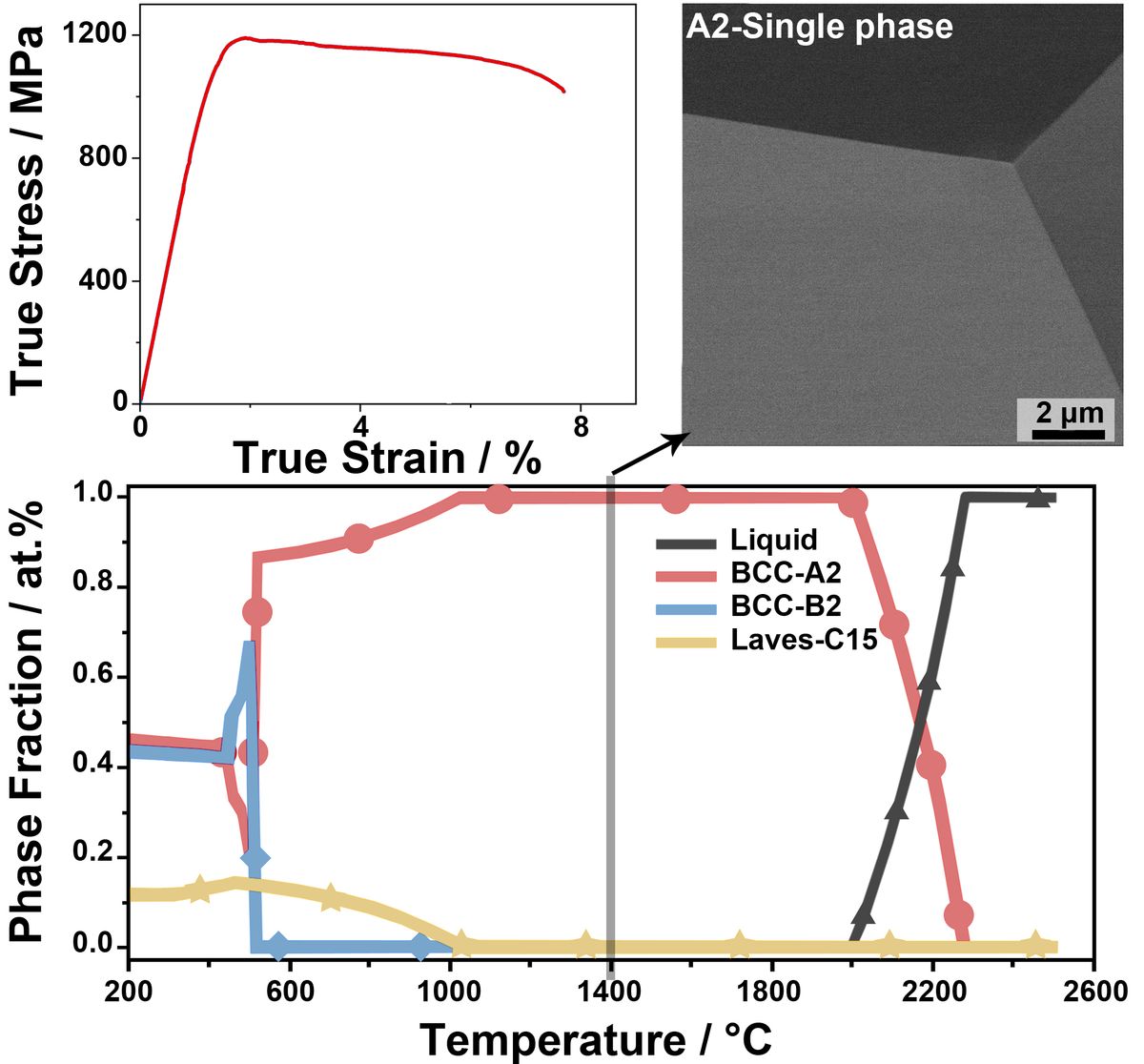

Refractory compositionally complex alloys (RCCAs) are known for their strength at high temperatures, oxidation resistance, and low density (6.5 to 8 g/cm3). Generally, these alloys possess disordered A2 crystal structure at high temperatures and B2 ordered crystal structure below an A2-B2 phase transition. In this condition, the alloys exhibit a lack of plastic deformation capability at room temperature (RT) and sudden failure. Therefore, stabilizing A2 crystal structure with optimized composition to achieve high strength and plastic deformability at low and high temperature simultaneously is promising.

Objectives

- Identification of Ti-Mo-Ta-Cr-Al alloy compositions with A2 crystal structure that plastically deform at room temperature

- Application of suitable strengthening to obtain high temperature strength

Investigations

- Synthesizing Ti-Mo-Ta-Cr-Al alloys with least contamination level

- Controlling alloy synthesis via HCGE for O/N uptake and ICP-EOS analysis during every stage of synthesis

- Studying the different mechanisms involved in microstructure formation and change as well as deformation at different temperatures using XRD, SEM, TEM, APT

Funding

Deutsche Forschungsgemeinschaft