Fine-structured, Austenitic-Martensitic Fe-Mn-C Alloys

Motivation

In this project, so-called AHSS (advanced high strength steels) are being investigated in collaboration with our colleagues from Prof. Tsuji's group at Kyoto University. AHSS are a group of novel steels that exhibit remarkable strength combined with good ductility and formability. The overarching aim of our activities on AHSS is to further increase the combination of strength and ductility.

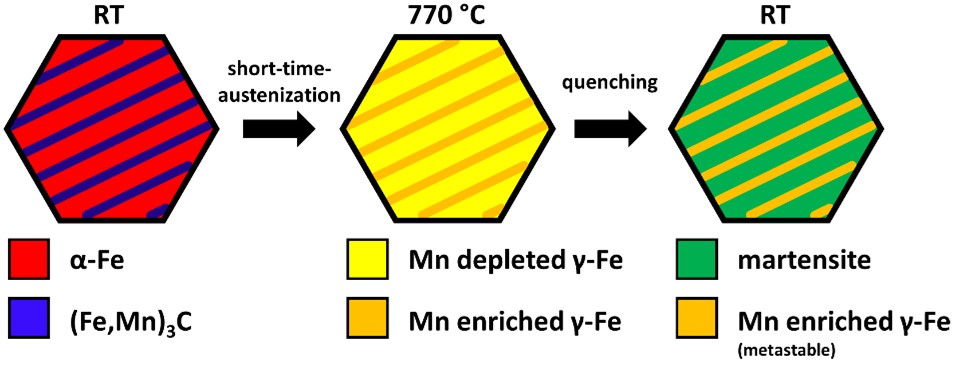

The alloys under investigation are eutectoid or near-eutectoid alloys within the Fe-Mn-C system. The outstanding property profile is achieved by a novel fine-structured microstructure consisting of martensite and metastable austenite. For this purpose, a fully pearlitic microstructure is first established. Mn dissolves substitutionally in both ferrite and cementite, but the equilibrium solubility in cementite is significantly higher. Accordingly, a lamellar and fibrous Mn concentration profile is formed, in which Mn enrichment occurs in cementite lamellae and Mn depletion in ferrite lamellae.

Following the formation of pearlite, a short-time-austenitization is carried out. After the complete phase transformation to austenite, a lamellar or fibrous Mn distribution is still present within the originally pearlitic colonies due to the slow diffusion of Mn. If the specimens are quenched in this state, a structure of austenite and martensite with comparable arrangement and morphology to the inital pearlite is subsequently present, since Mn has an austenite-stabilizing effect and strongly delays the martensite transformation in the Mn-enriched regions.

Objectives

Within the scope of project, the following research questions will be addressed:

- What are the limits of the synthesis of fine lamellar austenitic-martensitic microstructures in the Fe-Mn-C system with respect to the distribution of the dissolved elements in the pearlite, the volume fraction of the phases involved, the lamellar or microstructure sizes, and the defect density?

- Can the fundamental limitations be overcome by applying knowledge of interfacial pro-perties such as orientation relationships (in the pearlite and in the transformed micro-structure), morphology manipulation (e.g., spherodization), adjustment of concentration profiles at the interfaces, and the progress of martensitic transformation?

- What influence do fundamental changes in the microstructure have on the quasi-static mechanical properties obtained, such as strength, ductility and hardening?

Investigations

- Alloy design assisted by Thermo-Calc software

- Material synthesis via arc melting

- Parameter study on pearlite formation and short-time-austenitization

- Microstructure characterization via SEM, TEM and APT

- Determination of quasi-static mechanical properties

Funding

Graduate Funding from the State of Baden-Württemberg