Project 4: Thermomechanical properties of ceramic-nanocomposite-based monoliths and coatings

M.Sc. Yangyiwei Yang (1st cohort)

M.Sc. Yangyiwei Yang (1st cohort)

M.Sc. Mozhdeh Fathidoost (2nd cohort)

Supervisor: Prof. Bai-Xiang Xu, Prof. Karsten Albe

Polymer-derived ceramics (PDCs) nanocomposites, using Si(M)X with M = Ta, Hf and X = C, are intended as coatings to protect composite materials from extreme thermal and chemical conditions. However, the severe thermal mismatch between substrate and coating can destabilize composites, necessitating a rational design based on understanding thermo-mechanical properties. Investigations into Si(M)CX ceramics' properties are limited, demanding a combined experimental and theoretical approach to grasp their microstructural impact. Accelerated data-driven approaches and machine learning (ML) techniques are novel powerful tools to extract the structure-property relationship (SPR) for a given material system, which can lead to faster and more efficient materials design and discovery.

In the first cohort, a diffuse-interphase computational homogenization model was established to determine the effective thermal conductivity (keff) of complex PDCs, addressing the interface thermal resistance (Rs) through the diffuse-interphase method [1]. Furthermore, this model was employed for the sensitivity analysis of particulate ellipsoidal composites, aiming to determine the key geometrical and thermal properties that define the keff of such composites [2]. Afterward, by integrating both modeling and experimental results at different temperatures and Rs, the value of Rs were extracted in our material system, Si(Hf,Ta)C [3].

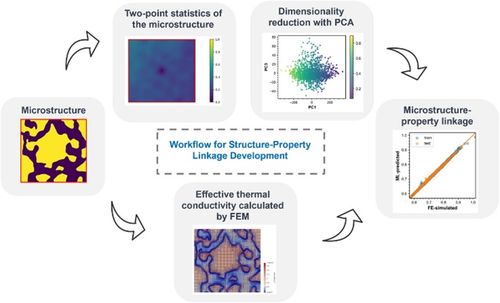

The second cohort project has established a SPR through the application of data-driven approaches and ML. This involved utilizing diverse synthetic microstructure images of Si(Hf,Ta)C alongside their corresponding calculated effective conductivity (keff) as the dataset [3].

(ML-based structure–property relation development workflow)

Our next steps involve comparing calculated effective properties with experimental results, and exploring optimum compositions and composite design for a multi-component top-coat in high-temperature applications is targeted. Additionally, we aim to develop a thermo-mechanical model to simulate the thermo-viscoelastic response under cyclic high-temperature applications.

[1] Y. Yang, M. Fathidoost, T. D. Oyedeji, P. Bondi, X. Zhou, H. Egger, B.-X. Xu, A diffuse-interface model of anisotropic interface thermal conductivity and its application in thermal homogenization of composites, Scripta materialia, 2022; 212: 114537, doi:10.1016/j.scriptamat.2022.114537.

[2] M. Fathidoost, Y. Yang, M. Oechsner, B.-X. Xu, Data-driven thermal and percolation analyses of 3D composite structures with interface resistance, Materials & Design, 2023; 227: 111746, doi:10.1016/j.matdes.2023.111746.

[3] Fathidoost, M., Yang, Y., Thor, N., Bernauer, J., Pundt, A., Riedel, R., & Xu, B. X. Thermal conductivity analysis of polymer‐derived nano‐composite via image‐base structure reconstruction, computational homogenization and machine learning. Advanced Engineering Materials, 2024, https://doi.org/10.1002/adem.202302021.