Our mission is to create advanced materials that perform reliably under extreme temperatures, playing a crucial role in modern energy conversion technologies. We analyze their properties, test their durability under real-world conditions, and refine them for large-scale industrial use. By pushing the boundaries of material science, we help develop more efficient and sustainable energy technologies for the future.

HiTemp materials are designed for reliable use at extreme temperatures where conventional materials fail due to inadequate mechanical properties, low radiation and corrosion resistance or thermal cycling requirements. They are essential for applications that require both high temperature resistance and sufficient ductility and strength under operating conditions.

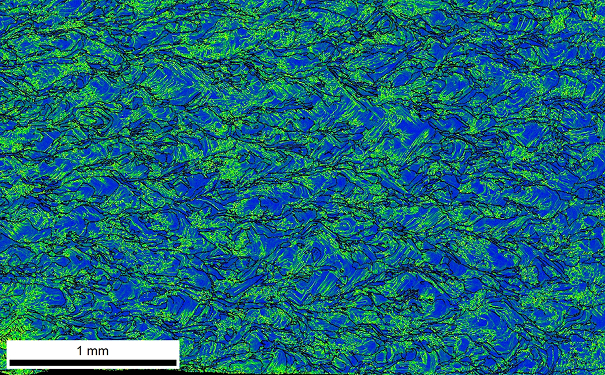

- Steels for fusion reactors

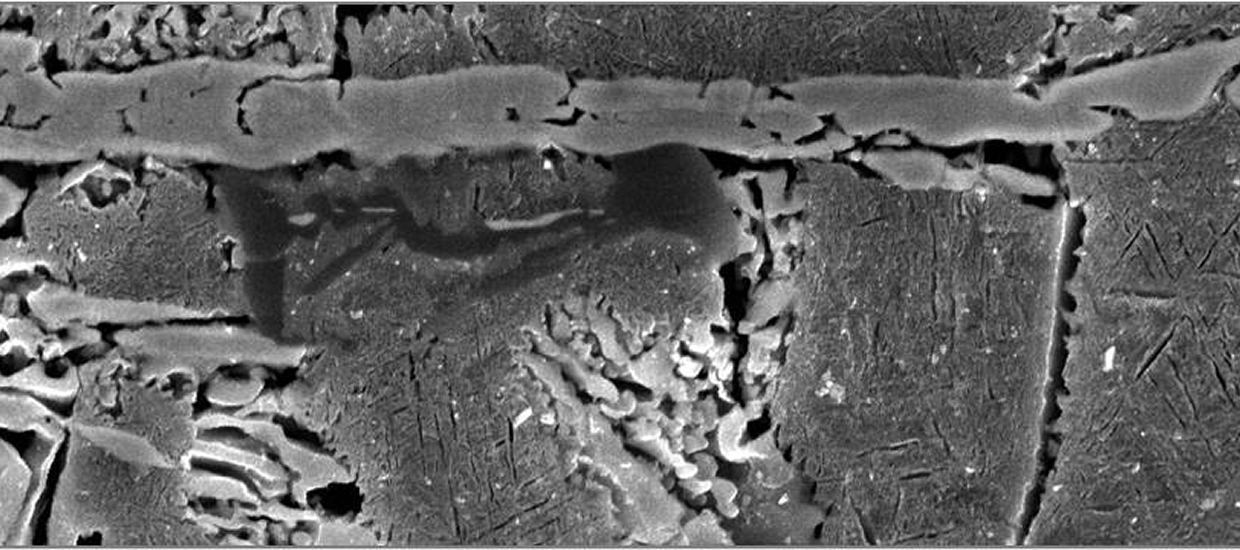

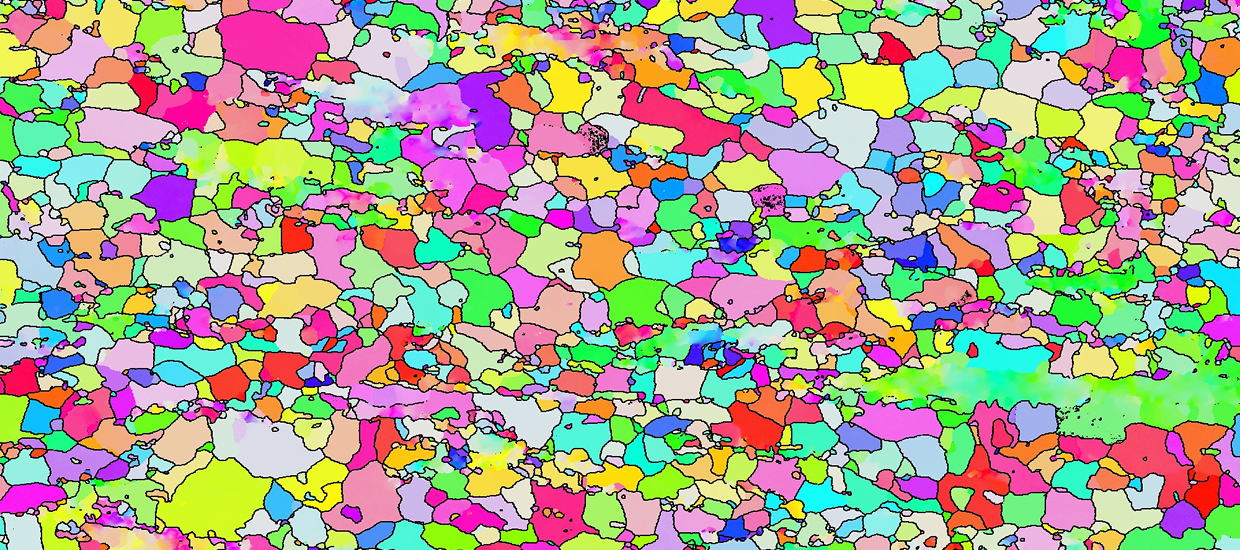

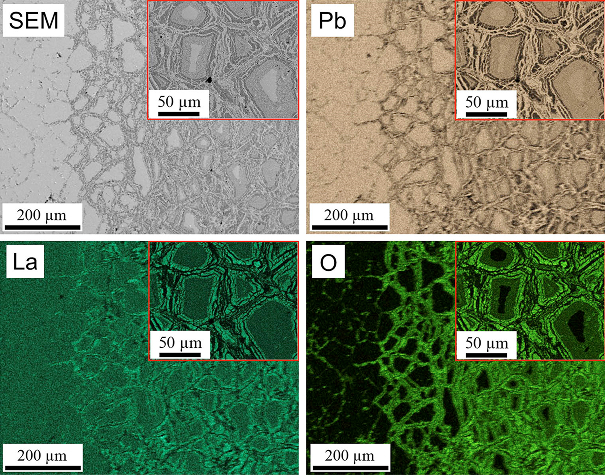

The group is working on improving steels for fusion reactors. The aim is to increase the high-temperature strength up to 600-700 °C and to investigate their behavior under neutron irradiation, thermal cycling and corrosion. - Materials for neutron multiplication

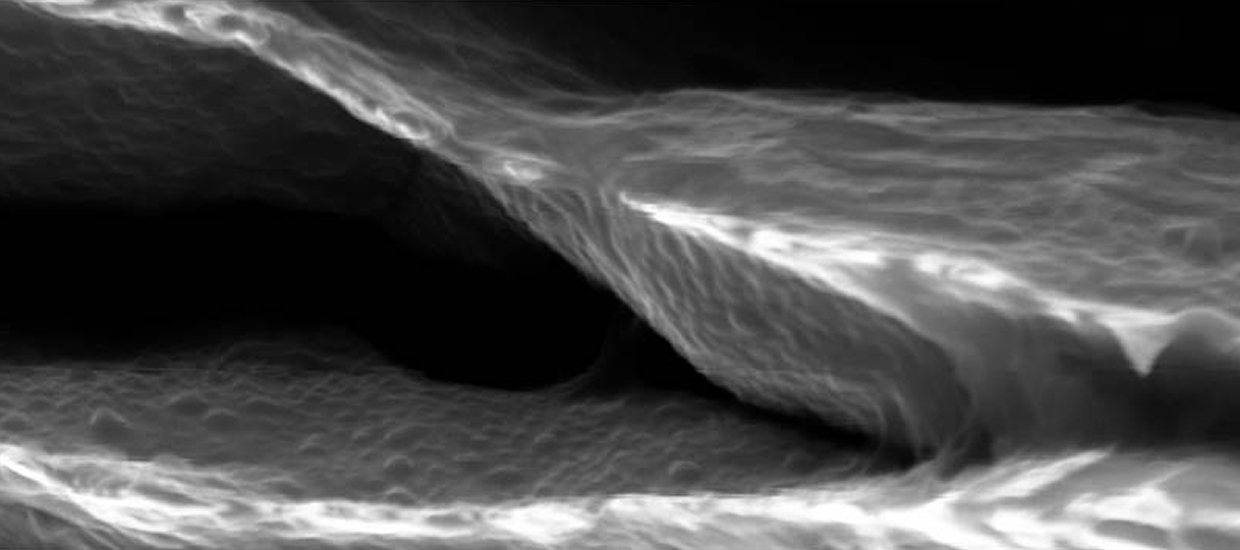

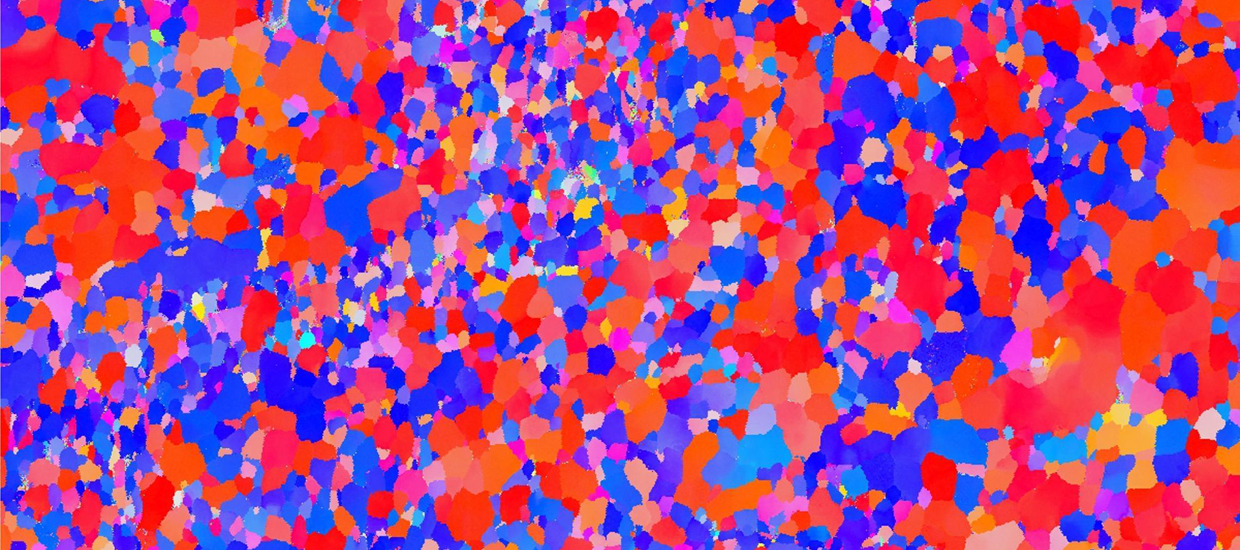

Beryllides and plumbides are being developed as neutron multipliers for fusion blankets, focusing on their performance under high temperatures, neutron irradiation and corrosion. - Copper in fusion reactors

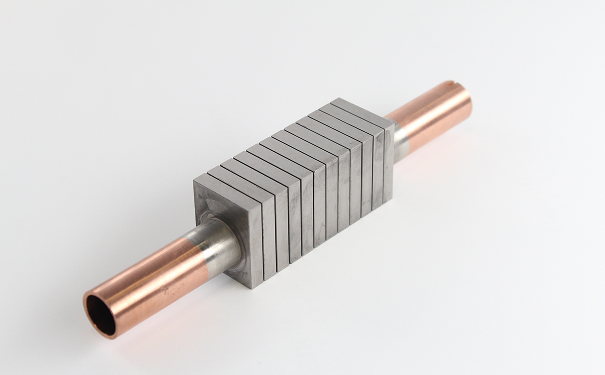

Research is focused on improving the high-temperature strength of copper for use in the most heat-stressed areas of fusion reactor divertors without compromising thermal conductivity. - Tritium breeder and neutron shielding materials

Research aims to improve the efficiency and production of tritium breeder materials and to develop more compact and effective solutions for neutron shielding in fusion reactor blankets. - High-temperature materials for aerospace propulsion systems

Chromium alloys are being investigated as lightweight alternatives to nickel-based superalloys. The challenge is to achieve a combination of creep resistance, corrosion resistance and ductility at high temperatures.

The HiTEMP laboratory has a comprehensive range of equipment for the production, processing, structural analysis and testing of physical and mechanical properties of materials:

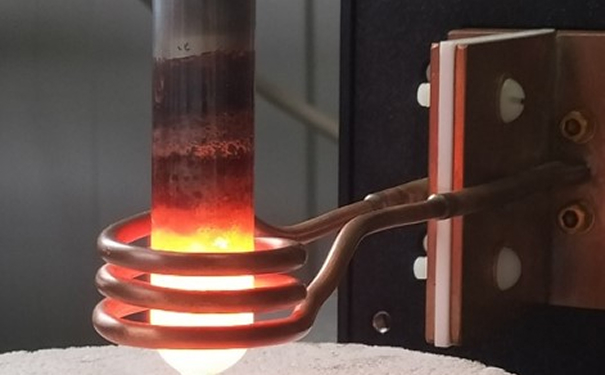

- Argon arc furnace: synthesizing alloys and intermetallic compounds under inert gas conditions.

- Glove boxes for powder processing: Ensuring a safe and controlled environment for working with reactive powders.

- Heat treatment furnaces: Including vacuum furnaces for high temperature annealing and processing.

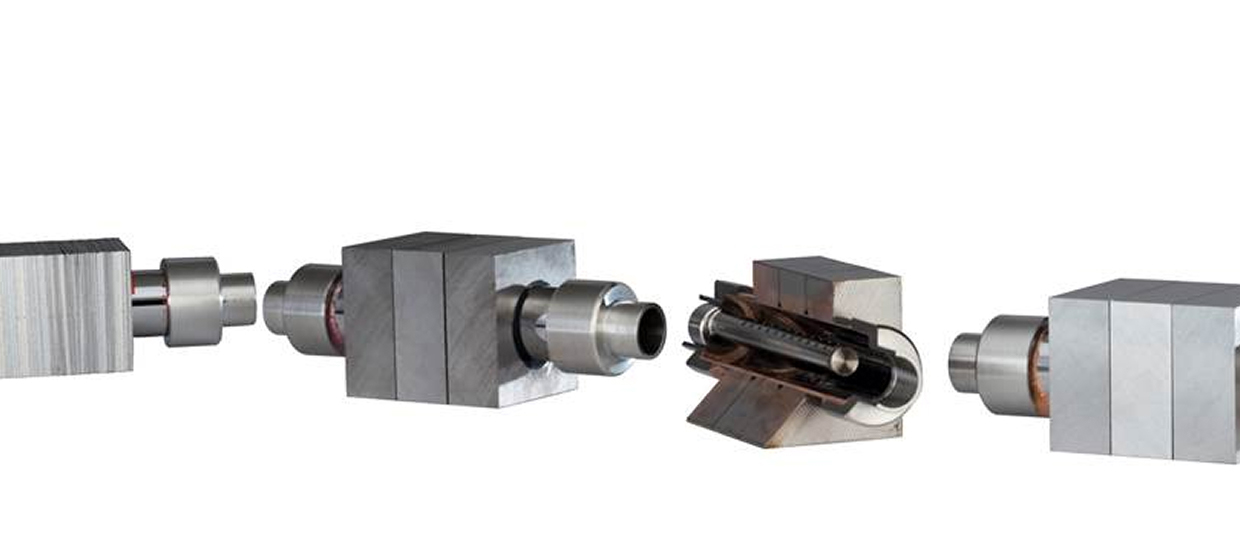

- Wire EDM machine (EDM): Precision cutting and forming of materials.

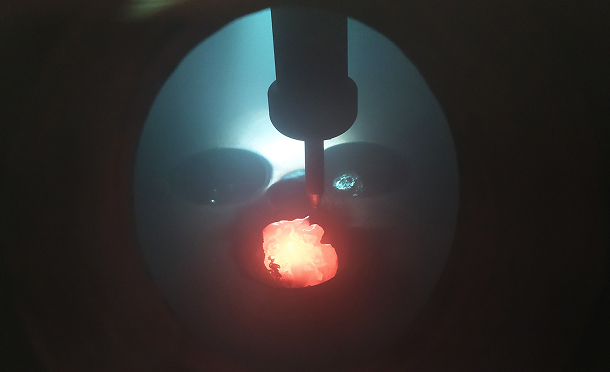

- Access to Hot Isostatic Pressing (HIP): Consolidation of powders and removal of internal porosity under high temperature and pressure.

- Universal testing machines: For tensile, compression, flexure and fatigue testing over a wide temperature range.

- Gleeble thermomechanics simulator: Advanced equipment for studying material behavior under controlled thermal and mechanical conditions, e.g. simulation of processes such as welding and forming.

- Creep testing machines: Evaluation of material performance under long-term loading at high temperatures.

- Notched bar impact testing machines for both low temperatures from -150 to +300 °C and high temperatures from 500 to 1200 °C.

We are actively involved in cooperation projects within the Helmholtz Association of German Research Centers (HGF) as well as in initiatives funded by EUROfusion, the BMBF (Federal Ministry of Education and Research) and the DFG (German Research Foundation). Our focus is on the following research areas:

- Development of high temperature resistant steels, including ODS steels, as structural and neutron resistant materials;

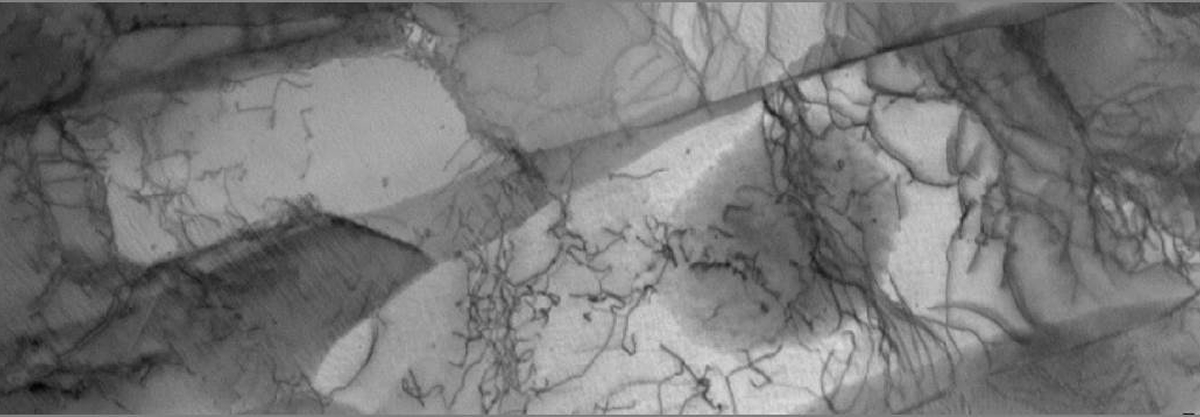

- Investigation of the effects of neutron irradiation on the structure and properties of steels, tungsten and functional materials;

- Intermetallic beryllides and plumbides for neutron multiplication in blanket systems of fusion reactors;

- Copper materials, including ODS copper, as heat sink materials for fusion technologies;

- Casting and 3D printing of RAFM steels (reduced-activation ferritic-martensitic steels) for fusion applications;

- Chromium alloys and composites for high-temperature applications

HiTEMP Lab offers cooperation in the form of research services:

- Mechanical tests under tension, compression and fatigue at temperatures of 20-1000 °C in a vacuum

- Charpy impact bending tests at temperatures from -200 °C to +500 °C

- Creep tests at high temperatures in air

- Performance of heat treatments in a vacuum and in air

- Hot isostatic pressing (HIP) up to 1400 °C

- Melting of alloys (up to 100 g for nickel alloys)

- Extensive testing of hazardous materials (e.g. beryllium, lead) in glove boxes (microstructure, mechanical properties)

- Corrosion tests in various environments

All research work is accompanied by scientific supervision. Damage analyses of components can be carried out or recommendations for material selection and processing can be given.

The HiTEMP laboratory actively collaborates with leading institutions and facilities to advance its research:

- Neutron Irradiation Facilities: BR2 (SCK CEN Mol, Belgium), BOR-60 (RIAR, Russia), HFIR (ORNL, USA) and VVR-K (Kazakhstan) for neutron irradiation studies.

- Ulba Metallurgical Plant, Kazakhstan: Production of beryllides and thermal cycle experiments.

- OCAS, Belgium: expertise in thermomechanical processing of advanced materials.

- Karlsruhe Beryllium Handling Facility (KBHF): Specialized gloveboxes for handling hazardous materials.

- ZOZ GmbH, Germany: Advanced powder production technologies.

- QST (Rokkasho, Japan): Collaboration in the development and characterization of structural and functional materials.

- Voestalpine, Austria: Foundry expertise for RAFM steels.

Publicationslist

Karlsruher Institut für Technologie. KIT (Ed.)

2026. Karlsruher Institut für Technologie (KIT)

Dwivedi, M.

2026. Technische Informationsbibliothek Hannover. doi:10.34657/30076

Amalfitano, D.; Metzger, A.; Autili, M.; Fulcini, T.; Hey, T.; Keim, J.; Pelliccione, P.; Scotti, V.; Koziolek, A.; Mirandola, R.; Vogelsang, A.

2026. ACM Transactions on Software Engineering and Methodology. doi:10.1145/3788879

Albajar, F.; Sanchez, F.; Alberti, S.; Avramidis, K.; Bader, M.; Bin, W.; Braunmueller, F.; Bruschi, A.; Cavinato, M.; Chelis, I.; Cindric, K.; Garavaglia, S.; Carannante, G.; Casal, N.; Chanois, J.; Dall’Acqua, D.; Darbos, C.; Ell, B.; Fasel, D.; Frei, M.; Gantenbein, G.; Genoud, J.; Goodman, T.; Granucci, G.; Hogge, J.-P.; Illy, S.; Ioannidis, Z.; Jelonnek, J.; Jin, J.; Jubany, E.; Legrand, F.; Leggieri, A.; Lievin, C.; Lescure, C.; Picas, O.; Raval, B.; Rzesnicki, T.; Romano, A.; Romanova, A.; Savoldi, L.; Siravo, U.; Thumm, M.; Tigelis, I.; Timperi, F.; Team, the F. O.

2025, October. 30th IAEA Fusion Energy Conference (FEC 2025), Chengdu, China, October 13–18, 2025

Kettner, C.; Poppenborg, R.; Hermann, B.; Haidn, O.; Stein, T.

2025. Sportwissenschaft: Vielfalt und Nachhaltigkeit!? Abstracts zum 27. Hochschultag der Deutschen Vereinigung für Sportwissenschaft; Münster, 16.-19.09.2025; Strauß, B., Tietjens, M., van Meurs, E. & Henning, L. (Hrsg.)

Roth, C.; Maier, L.; Abel, B.; Roigk, P.; Rapp, K.; Schmidberger, O.; Bongartz, M.; Maier, S.; Wirth, I.; Metz, B.; Immel, D.; Finger, B.; Schölch, S.; Büchele, G.; Deuster, O.; Koenig, H.-H.; Gottschalk, S.; Dams, J.; Micol, W.; Bauer, J. M.; Wensing, M.; Benzinger, P.

2024. BMC geriatrics, 24 (1), Art.: 720. doi:10.1186/s12877-024-05277-7

Maier, L.; Benzinger, P.; Abel, B.; Roigk, P.; Bongartz, M.; Wirth, I.; Cuvelier, I.; Schölch, S.; Büchele, G.; Deuster, O.; Bauer, J.; Rapp, K.; Ullrich, C.; Wensing, M.; Roth, C.

2024. European geriatric medicine, 15 (5), 1369–1382. doi:10.1007/s41999-024-01027-5

Qiu, Y.; Álvarez, I.; Ambrožič, K.; Berry, T.; Bieńkowska, B.; Chohan, H.; Čufar, A.; Dworak, D.; Lopez-Revelles, A.; Lopez, V.; Mota, F.; Martinez-Echevarria, M.; Piotrowski, T.; Serikov, A.; Stankunas, G.; Tidikas, A.; Taling, L.; Tracz, G.; Wiącek, U.; Ansorge, M.; Jimenez-Rey, D.; Mendoza, E.; Malec, J.; Martínez-Serrano, J.; Akbaş, S.

2025. 30th IAEA Fusion Energy Conference (FEC 2025), Vienna, Austria, October 13–18, 2025

Sanchez Ortiz, G.; Löberbauer, M.; Andrić-Tomašević, N.; Mandic, O.; Pavelić, D.; Demir, V.; Keys, P. W.; Meijers, M. J. M.; Rugenstein, J. K. C.

2026. Journal of Hydrology: Regional Studies, 64, Art.-Nr.: 103214. doi:10.1016/j.ejrh.2026.103214