Research Areas

The current research areas focus on the following topics:

|

|

|

|

|

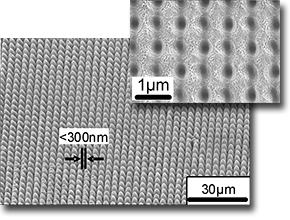

| Laser-structured LiCoO2 Cathode thin film (left) and nanostructured a-C:H film (right). |

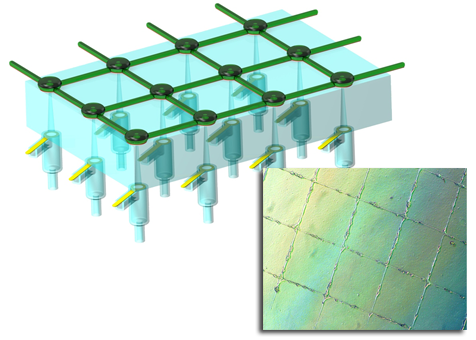

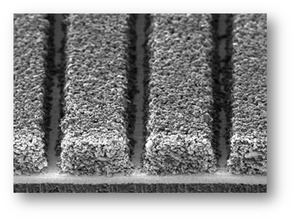

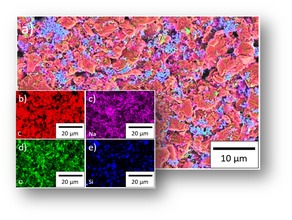

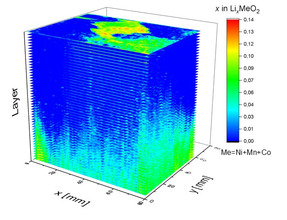

Development of polymer-based components for analysis of cell systems. | Laser-structured thick-film electrode for optimising electrochemical properties. | Material development for electrodes for the production of Li-ion batteries (Element distribution). | LIBS analysis: 3D lithium distribution of a cycled anode (post-mortem). |

- Laser structuring and laser annealing of electrode thin and thick films as well as current collectors to improve the electrochemical performance (lifetime, high rate capability) of lithium-ion batteries (LIBs) and to increase the energy and power density at cell level (3D battery concept).

- Laser-induced plasma spectroscopy (LIBS) on battery materials as an analysis method for quality-controlled development of slurries as well as for investigation and visualisation of degradation processes (post-mortem), 2D surface mapping, depth profile (3D), multi-element analysis.

- Large area laser material processing of battery materials (anode / cathode / separator / current collector) in roll-to-roll (R2R) process. Laser structuring at µm and nm scale, laser cutting, notching, slitting, laser ablation.

- Electrochemical analyses on electrode materials to evaluate cell chemistry and cycling lifetime. Galvanostatic analyses (GCPL), electrochemical impedance spectroscopy (EIS), cyclic voltammetry (CV), galvanostatic intermittent titration technique (GITT).

- Development of surface functionalisation (e.g., wetting behaviour), micro- and nano-structuring of surfaces and thin films for biological and microfluidic applications (including in combination with micro-printing techniques).

- Microstructuring of polymers with CO2 and UV laser radiation.

- Laser printing (LIFT) & structuring of thin films.