The scientific research of the Microstructural Analysis group focuses on the application of various microscopic methods for material characterization. One of the main research areas is the multiscale investigation of the microstructure of metallic materials, including ferritic-martensitic alloys, Cu-based materials, tungsten, and beryllium in different modifications. The research analyzes the grain structure, as well as the formation and distribution of foreign phases and precipitates in metals, in order to understand their development and impact on mechanical properties. Furthermore, the influence of thermomechanical treatments on the development of grain structure, precipitate formation, and dislocation structure in metallic materials is examined. Another key research focus is the formation of radiation-induced defects and foreign phases.

The group collaborates closely with other research groups in the Department of Metallic Materials to explore the relationships between microstructure, mechanical properties, and various theoretical models.

Determination of the microstructure of low-activation 9%Cr (ODS) steels

New 9%Cr steels specially developed for fusion (EUROFER97 further development) are characterized in detail. These investigations include, for example

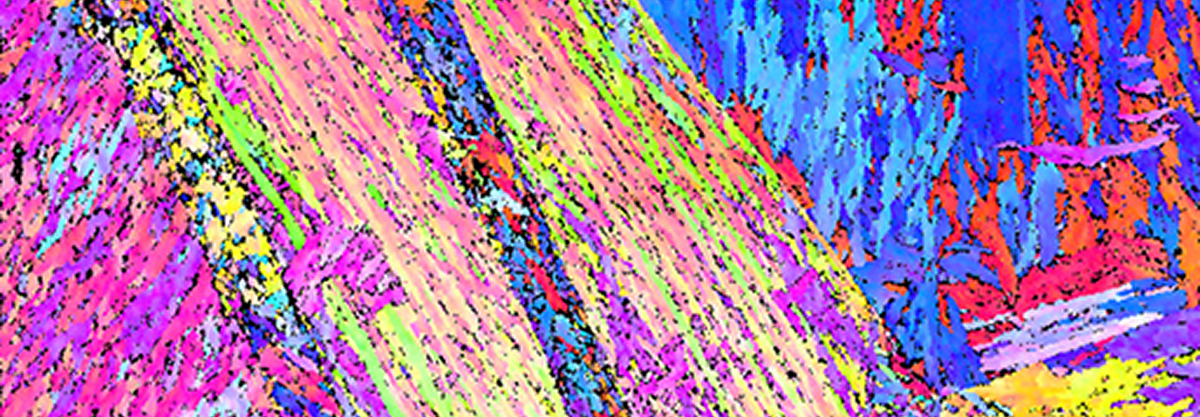

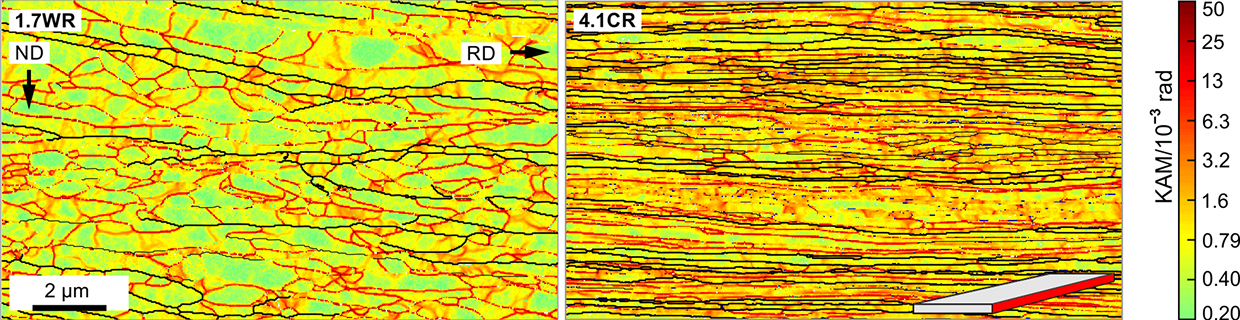

- Determination of the grain and sub-grain structure in metallic materials using electron-backscatter-diffaction (EBSD).

- Microstructure characterization (light microscopy)

- Determination of the structure and composition of nanoscale secondary precipitates (nitrides and carbides) in metals and their number density

- The results obtained serve to explain the measured mechanical material characteristics (tensile strength, fracture toughness, fatigue...), possibly as an indication for modifying the manufacturing process and as a reference for recognizing material changes under neutron irradiation at different temperatures.

Radiation-resistant ODS copper and CuCrZrV alloy for high-temperature applications

CuCrZr is the basic heat sink material for the water-cooled plasma radiation units in the DEMO divertor. The disadvantage and risk of this material lies in the radiation-induced softening at temperatures of around 350 °C and above. The aim is to provide a radiation-resistant material that can be produced by industrial processes in technologically relevant semi-finished products and quantities. The microstructure analysis group carries out the following

- Characterization of the microstructure on a micrometer scale using SEM-EBSD

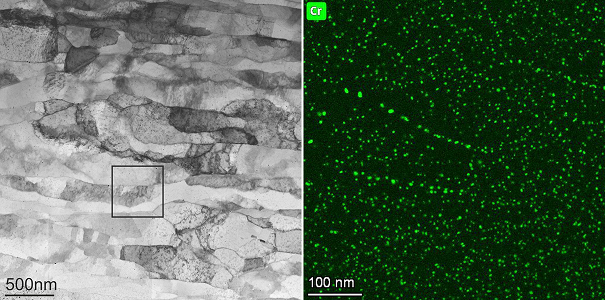

- Determination of the structure and composition of nanoscale particles (Al2O3, Cr-nanoparticles or Y2O3) and their number density using transmission electron microscopy

- The results obtained serve to explain the measured mechanical material characteristics (tensile strength, fracture toughness, fatigue...), possibly as an indication for modifying the manufacturing process and as a reference for recognizing material changes under neutron irradiation at different temperatures.

TEM investigations on functional thin films

During their lifetime in the pulsed DEMO-Tokamak reactor, the material coatings can change significantly due to the following factors

- Thermal expansion mismatch between the coating and the low-activation steel substrate

- surface defects/roughness of the substrate

- chemical attack by the Pb-16Li with formation of mixed compounds and oxides that can reduce the effectiveness of the coating

- Scanning and transmission electron microscopy is used to document material changes in the protective coatings with the duration of liquid metal corrosion

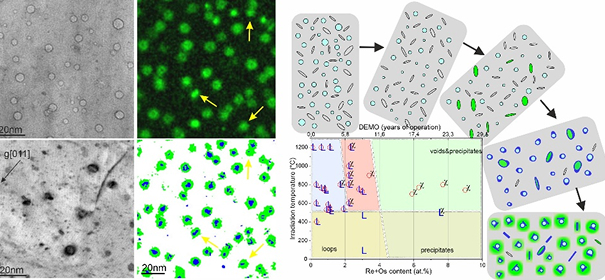

Microstructure characterization of neutron irradiated materials

The change in the mechanical properties of metallic materials due to neutron irradiation is determined by the formation of defects such as nanometer-sized pores or He-filled vesicles and dislocation rings. These are significantly influenced by the irradiation temperature and dose. The task of the transmission electron microscope is to image and quantitatively characterize them.

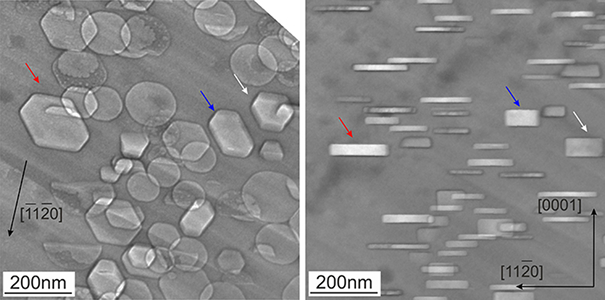

Neutrons induced the formation of pores and dislocation rings as well as the consequent formation of RE/Os particles from transmutation production in tungsten.

Beryllium and beryllides

Investigation of Be and beryllides from HIDOBE irradiation experiments. Imaging of hexagonal vesicles and 3D reconstruction of their shape.

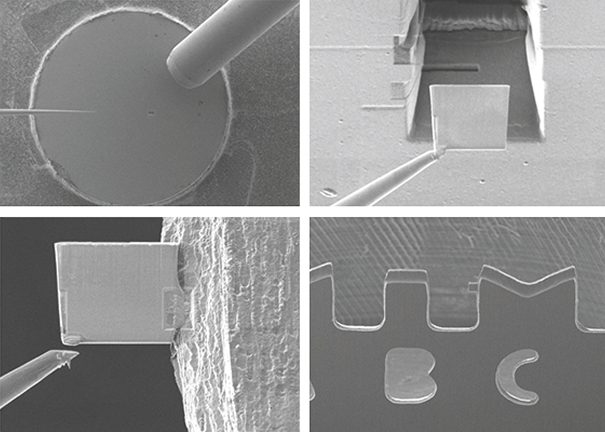

Target preparation of TEM lamellae of neutron irradiated beryllium at the Focused Ion Beam (FIB/SEM) in the control area of the Fusion Materials Laboratory.

Scientific inquiry into various low activation steels irradiated up to 16dpa in the temperature range from 250°C to 450°C as part of the SPICE irradiation program.

Investigation of various low activation steels irradiated up to 32dpa at a temperature of 330°C as part of the ARBOR irradiation program.

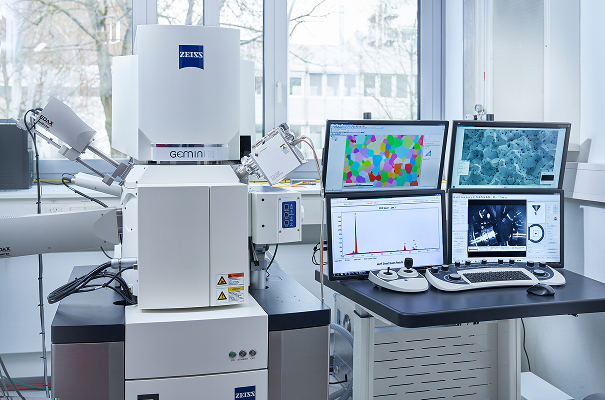

Focused Ion Beam Crossbeam-Auriga Zeiss

Crossbeam FIB SEM device with EBSD detector (EDEX, 2D and 3D) and the possibility of target preparation of different materials.

Scanning electron microscope Zeiss Merlin

- Scanning electron microscope (field mission source) with high-resolution electron column.

- Complete analytics such as EDS, WDS, EBSD (EDAX) and Plasmar-Cleaner for contamination-reduced element analysis.

- alos F200X is a 200 kV XFEG Scanning Transmission Electron Microscope (S/TEM), designed for fast, precise analytical characterization of nanostructures.

- Transmission electron microscope with Schottky X-FEG emitter with variable working voltage of 60, 80, 120 or 200 kV.

- Ceta 16M (4k x 4k) camera with in-situ function. STEM recordings are possible with HAADF, DF2, DF4 and BF-STEM detectors.

- Super-X EDS detector enables fast acquisition of 2D EDX element distribution images. The maximum solid angle of the detectors is 0.9 srad.

- Gatan Enfinium ER spectrometer enables EELS analysis with UltraFast DualEELS imaging.

Thermo Scientific Tecnai F20

Analytical transmission electron microscope with field emission source, 200 kV acceleration voltage.

Equipped with the option of combining electron energy loss spectroscopy, EELS (Gatan) with energy dispersive X-ray spectroscopy, EDS (EDAX), a high-angle annular dark field detector, HAADF, an ACOM module for orientation mapping as well as a tensile test holder and heating element for in-situ tensile tests at up to 1000°C

- Analytical transmission electron microscope with field emission source, 200 kV acceleration voltage.

- Equipped with the possibility of combining electron energy loss spectroscopy, EELS (Gatan) with energy dispersive X-ray spectroscopy, EDS (EDAX), a high-angle annular dark-field detector, HAADF.

- The microscope is located in the control area with the possibility of characterizing radioactive samples and toxic materials (e.g. beryllium).

Fully equipped metallography:

- Light microscopes (reflected light microscopes, stereomicroscope) with software for microstructure evaluations

- Macro and micro hardness tester and nanoindenter (e.g. CSM) with automated measurement

- Preparation of metallic samples for microstructure and structure analysis for scanning electron microscopes

- Preparation of thin sections for transmission electron microscopy

- Electro-chemical surface etching

The Microstructure Analysis Group offers you scientific analyses of your problems. Our services in this area include

Metallographic investigations

- metallographic microsections

- Light microscopic examinations of microstructures, inclusions or defects

- Preparation of components for further examination

Focused Ion Beam

- Target preparation of TEM samples, serial sections in materials for 3D depth analysis

Electron microscopy

- Scanning electron microscopy with chemical analysis (identification of phases and structural components, inclusions, microstructure)

- Transmission electron microscopy (high-resolution imaging of microstructures at nanometer level, chemical analysis (EDS/EELS), crystallographic investigations (ASTAR)

- Chemical analysis

- EDS

- EELS

We offer examinations with all available devices. Please contact us for further details and an individual offer!

Microstructure analysis projects

We are actively involved in cooperation projects within the Helmholtz Association of German Research Centers (HGF) as well as in initiatives funded by EUROfusion, the Federal Ministry of Education and Research (BMBF) and the German Research Foundation (DFG).

Our research focuses on the following topics:

- Investigation of the microstructure of 9Cr-RAFM steels (Reduced-Activation Ferritic-Martensitic Steels) with improved high-temperature mechanical properties compared to EUROFER97.

- Experimental microscopic studies on the formation of radiation damage in various fusion materials, e.g. tungsten and tungsten alloys, copper-based alloys (e.g. CuCrZrV) and RAFM steels.

- Microstructural research into materials for neutron multiplier systems, in particular beryllium and beryllides.

- Microscopic investigation of complex coating systems for corrosion protection.

EUROFUSION

Details and background information on the EUROfusion program are available on the web at https://euro-fusion.org.

WPMAT

One of the main objectives of WPMAT-SDQ is the development of 9Cr-RAFM steels with improved mechanical properties at high temperatures compared to EUROFER under metallurgical reference conditions (in terms of strength, creep behavior and creep fatigue), which can be used at temperatures up to about 650 °C, while EUROFER cannot be used above about 550 °C. This is achieved by special thermal or heat treatment processes. This is achieved by special thermal or thermomechanical treatments and changes in chemical composition.

MAT-IRRAD

The project includes the organization and execution of irradiation experiments and subsequent characterization of neutron irradiated materials for fusion technology.

MAT-IREMEV

The project comprises the material-integrated modeling of radiation effects and their experimental validation: experimental studies on the formation of radiation damage in fusion materials.

Publications

Busch, S.; Ferrario, P. G.; Henk, A.-K.; Engelbert, A. K.; Wittek, O.; Seifert, S.; Bub, A.; Mack, C. I.; Hieronimus, B.

2026. JMIR Research Protocols, 15, Article no: e81857. doi:10.2196/81857

Wunsch, T.; Hoffmann, M.; Woll, A.

2026. QLB@BW – Eine Bestandsaufnahme der Lehrkräftebildung in Baden-Württemberg. Hrsg.: C. Sälzer, 93–114, Waxmann Verlag

Tarantini, C.; Talantsev, E. F.; Pallecchi, I.; Hänisch, J.; Tallon, J. L.; Larbalestier, D. C.

2026. Superconductor Science and Technology, 39 (2), 021001. doi:10.1088/1361-6668/ae417f

Teramae, T.; Wild, J.; Huang, J.; Chassaing, D.; Issariyapat, A.; Eusterholz, M. K.; Kariya, S.; Umeda, J.; Kondoh, K.

2026. Journal of Alloys and Compounds, 1057, 186733. doi:10.1016/j.jallcom.2026.186733

Masuda, L.; Matsumoto, R.; Takano, Y.; Walter, K.; Jung, A.; Martinelli, A.; Hänisch, J.; Iida, K.

2025, February 14. 2nd Iron-based Superconductors: Advances towards applications (IBS2app 2025), Miyazaki, Japan, February 13–15, 2025

Welz, B.; Pierotti, S.; Fitzgerald, T.; Thumberger, T.; Suzuki, R.; Watson, P.; Fuss, J.; Cordeiro da Trindade, T.; Defranoux, F.; Ferreira, M.; Naruse, K.; Loosli, F.; Gierten, J.; Wittbrodt, J.; Birney, E.

2026. Cell Genomics, Art.Nr: 101164. doi:10.1016/j.xgen.2026.101164

Ivanov, V.; Markowz, G.; Schmitt, F.; Pauleikhoff, J.

2025. CBR Sustainability Partners. doi:10.5445/IR/1000190908

Baruah, S.; Popov, R.; Hanisch, J.; Matias, V.; Bagrets, N.; Selskij, V.; Holzapfel, B.

2025, September 22. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Baruah, S.; Singhal, S.; Dam, M.; Jelden, P.; Hänisch, J.; Börner, M.; Arndt, T.; Gerrit Korvink, J.; Holzapfel, B.

2025, June 30. 1st Microscale NMR and MRI conference (2025), Ettlingen, Germany, June 29–July 2, 2025

Masuda, L.; Moorinaga, K.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, October 13. Materials Research Meeting (2025), Yokohama, Japan, December 8–13, 2025

Publications of microstructure analysis

Busch, S.; Ferrario, P. G.; Henk, A.-K.; Engelbert, A. K.; Wittek, O.; Seifert, S.; Bub, A.; Mack, C. I.; Hieronimus, B.

2026. JMIR Research Protocols, 15, Article no: e81857. doi:10.2196/81857

Wunsch, T.; Hoffmann, M.; Woll, A.

2026. QLB@BW – Eine Bestandsaufnahme der Lehrkräftebildung in Baden-Württemberg. Hrsg.: C. Sälzer, 93–114, Waxmann Verlag

Tarantini, C.; Talantsev, E. F.; Pallecchi, I.; Hänisch, J.; Tallon, J. L.; Larbalestier, D. C.

2026. Superconductor Science and Technology, 39 (2), 021001. doi:10.1088/1361-6668/ae417f

Teramae, T.; Wild, J.; Huang, J.; Chassaing, D.; Issariyapat, A.; Eusterholz, M. K.; Kariya, S.; Umeda, J.; Kondoh, K.

2026. Journal of Alloys and Compounds, 1057, 186733. doi:10.1016/j.jallcom.2026.186733

Masuda, L.; Matsumoto, R.; Takano, Y.; Walter, K.; Jung, A.; Martinelli, A.; Hänisch, J.; Iida, K.

2025, February 14. 2nd Iron-based Superconductors: Advances towards applications (IBS2app 2025), Miyazaki, Japan, February 13–15, 2025

Welz, B.; Pierotti, S.; Fitzgerald, T.; Thumberger, T.; Suzuki, R.; Watson, P.; Fuss, J.; Cordeiro da Trindade, T.; Defranoux, F.; Ferreira, M.; Naruse, K.; Loosli, F.; Gierten, J.; Wittbrodt, J.; Birney, E.

2026. Cell Genomics, Art.Nr: 101164. doi:10.1016/j.xgen.2026.101164

Ivanov, V.; Markowz, G.; Schmitt, F.; Pauleikhoff, J.

2025. CBR Sustainability Partners. doi:10.5445/IR/1000190908

Baruah, S.; Popov, R.; Hanisch, J.; Matias, V.; Bagrets, N.; Selskij, V.; Holzapfel, B.

2025, September 22. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Baruah, S.; Singhal, S.; Dam, M.; Jelden, P.; Hänisch, J.; Börner, M.; Arndt, T.; Gerrit Korvink, J.; Holzapfel, B.

2025, June 30. 1st Microscale NMR and MRI conference (2025), Ettlingen, Germany, June 29–July 2, 2025

Masuda, L.; Moorinaga, K.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, October 13. Materials Research Meeting (2025), Yokohama, Japan, December 8–13, 2025

Baruah, S.; Popov, R.; Hänisch, J.; Matias, V.; Bagrets, N.; Nast, R.; Singhal, S.; Korvink, J.; Barth, C.; Ballarino, A.; Holzapfel, B.

2026. IEEE transactions on applied superconductivity, 36 (5), Article no: 6602405. doi:10.1109/TASC.2026.3661464

Masuda, L.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, September 23. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Jamatia, T.; Pechancová, V.; Paul, D.; Buchgeister, J.; Baumann, M.; Ersoy, H.; Erakca, M.; Saha, P.

2026. iScience, Article no: 115110. doi:10.1016/j.isci.2026.115110

Zhong, S.; Sui, P.; Holtappels, P.; Navarrete, A.; Li, F.; Dittmeyer, R.

2025. Chemical Engineering Journal, 509, Art.-Nr.: 161119. doi:10.1016/j.cej.2025.161119

Laborgne, P.; Wieczorek, W.; Wendeberg, E.

2026. Book of Abstracts from the Urban Europe Research Alliance (UERA) Conference 2026. Ed.: E Lissandrello, 34–35, Aalborg University Open Publishing