High-temperature net STA 449 thermobalance for simulative thermal analyses under dry and vaporous atmospheres.

High-performance Setaram thermogravimetry system for experiments up to 1500°C.

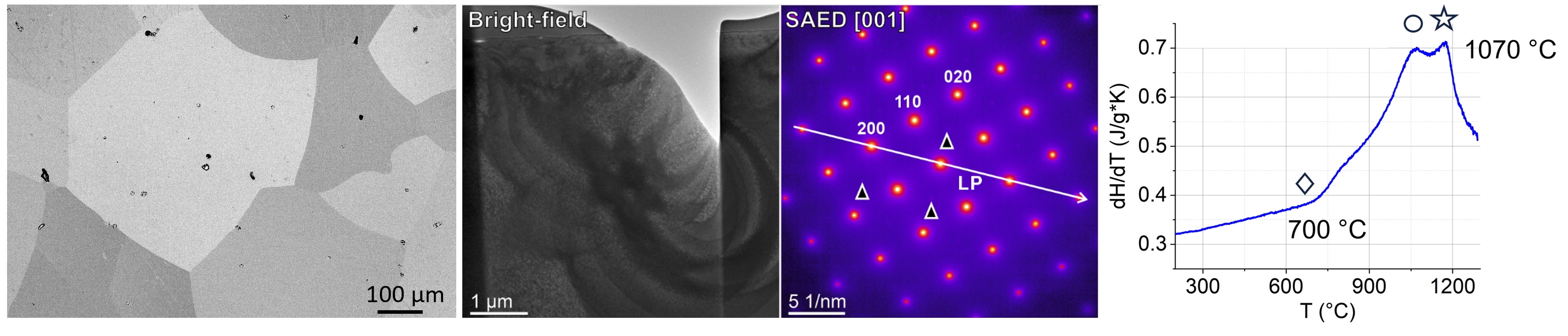

High-resolution -Netsch DSC 404 F1 Pegasus differential calorimeter for precise thermal characterization up to 2000°C.

Arc Meter AM 500 for sample production and melting at temperatures up to 3500°C.

Specially developed heat treatment furnace with integrated quenching function for controlled heat treatment up to 1600°C.

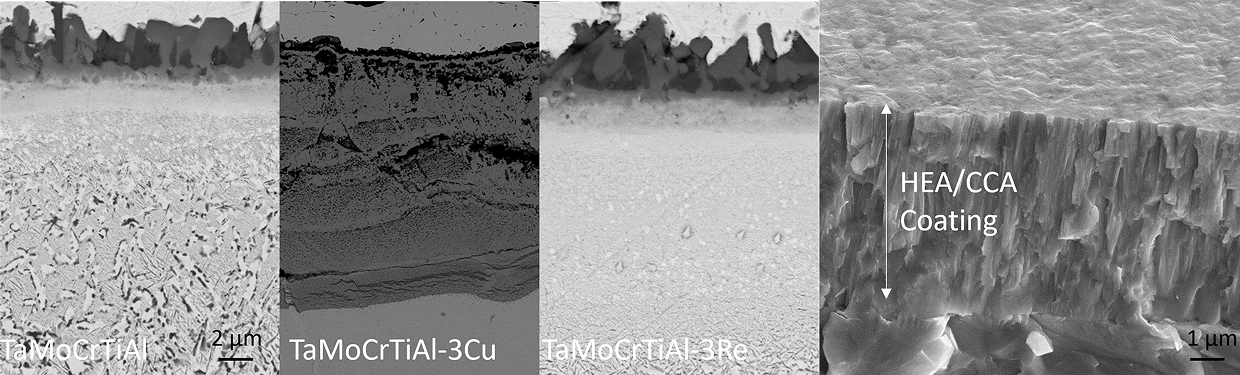

Various oxidation and heat treatment furnaces with operating temperatures above 1600°C.

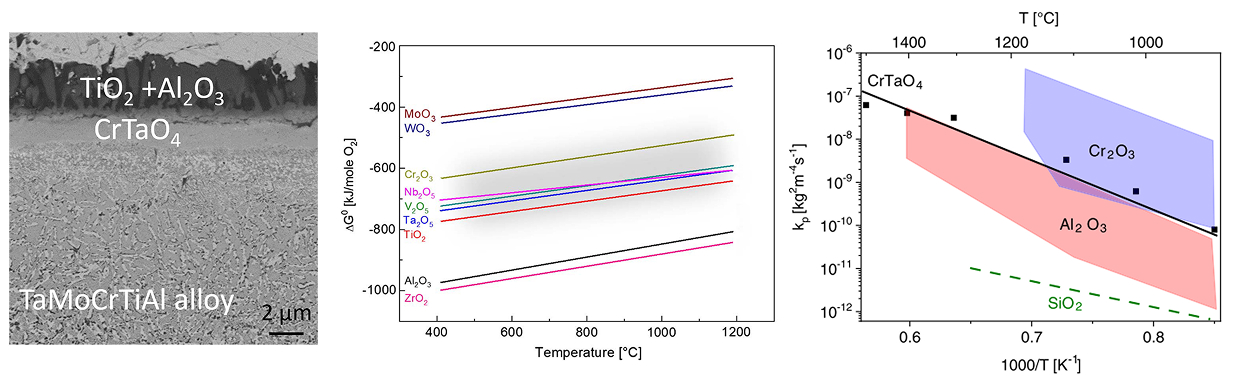

Fully equipped metallographic and microscopic laboratory for microstructural analysis, including light microscopy and scanning electron microscopy (SEM) with energy dispersive X-ray spectroscopy (EDX).