Our group performs atomistic simulations of material behavior under extreme environmental conditions together with experimental validation of model predictions. The main field of application are functional and structural materials for nuclear fusion, which have to withstand high temperatures, irradiation with fast neutrons that permanently damage the crystal lattice, and high concentrations of gaseous atoms such as helium and hydrogen isotopes from transmutation processes. Such materials are developed and characterized in the "Metallic Materials" department.

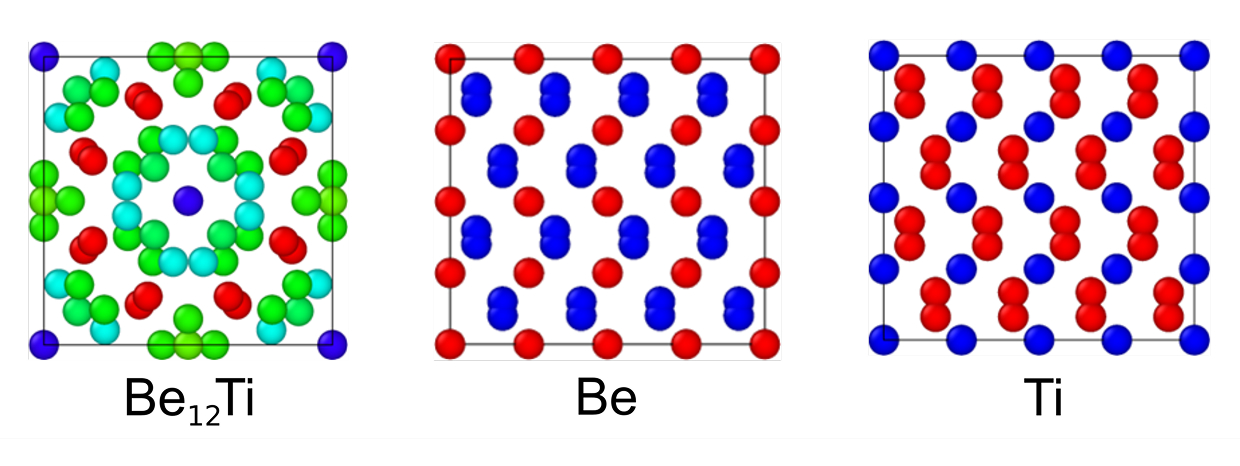

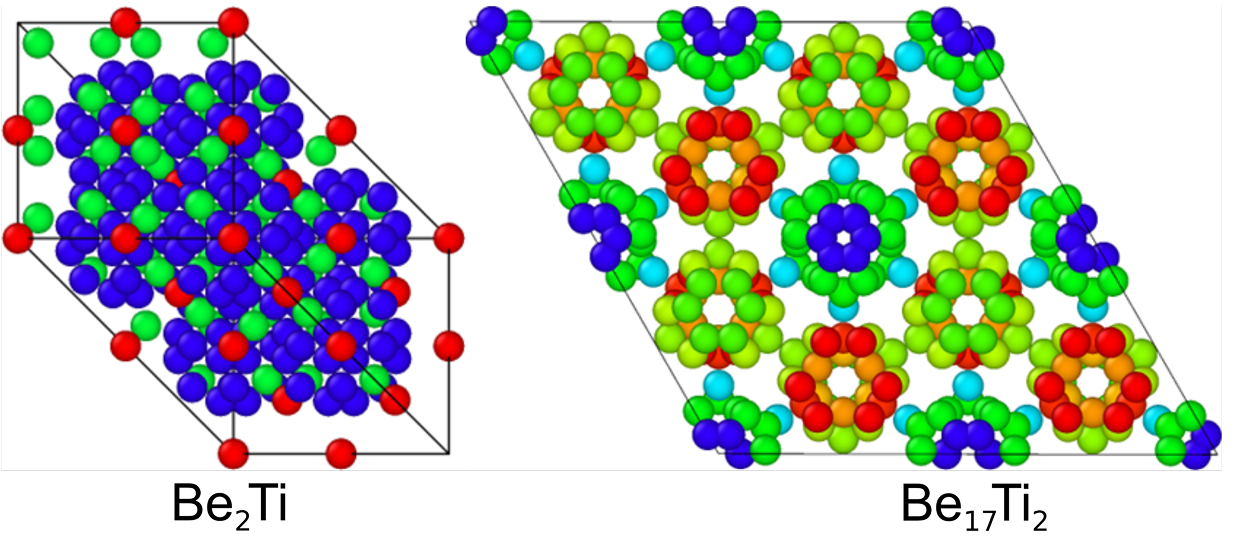

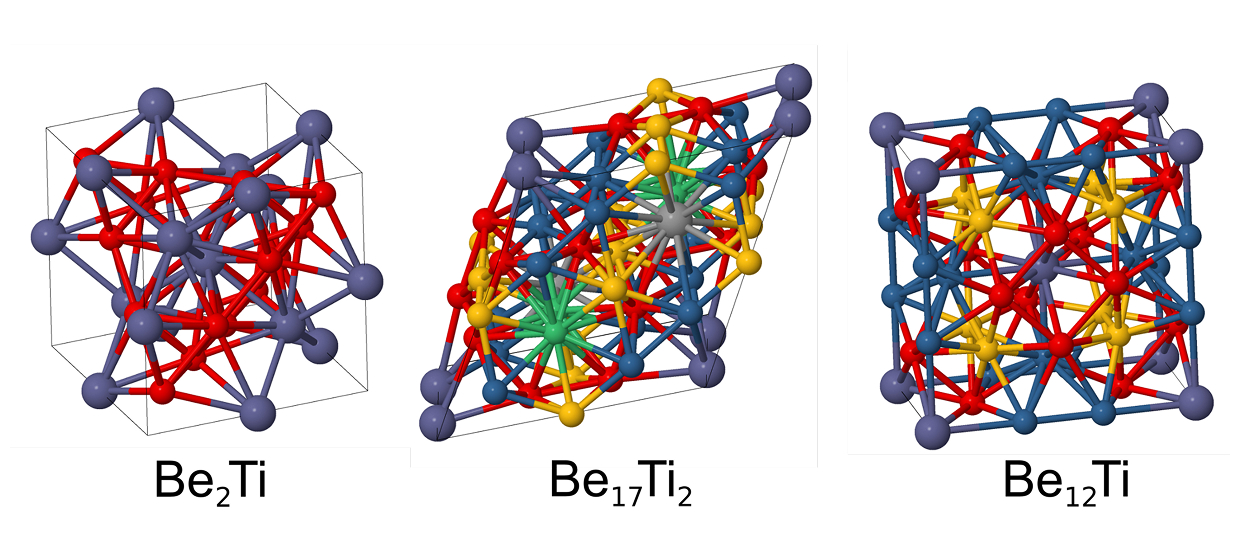

Beryllium and beryllium alloys such as TiBe₁₂ are seen as neutron multipliers for future nuclear fusion reactors. They are intended to compensate for neutron loss and thus generate additional tritium, which together with deuterium serves as fuel for the fusion reaction and enables self-sustainable fuel cycles.

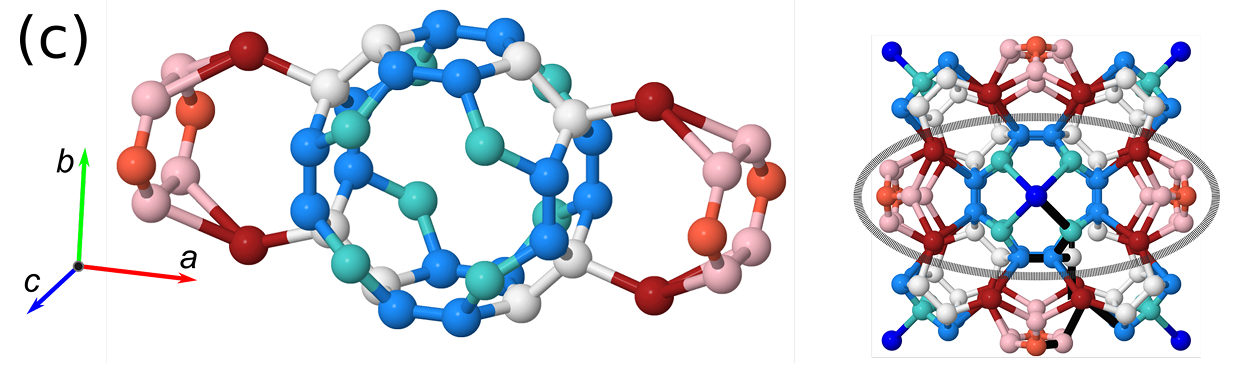

Our group is investigating beryllium as a neutron multiplier material for the DEMO fusion reactor. For the first time, we were able to show that in irradiated beryllium the trapped tritium accumulates on the walls of the helium bubbles, while the helium fills the bubble volume as a gas (see figure). This effect explains the deep binding of tritium in beryllium and led to the development of advanced neutron multipliers with reduced tritium retention. Our research contributes to improving the safety and efficiency of next-generation fusion reactors.

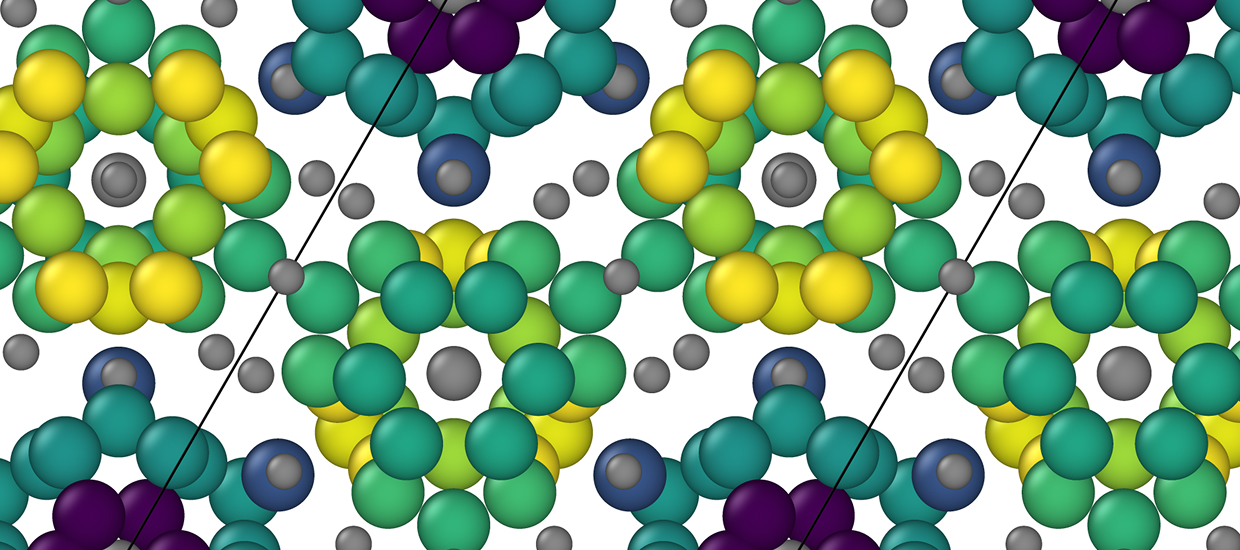

EELS maps of (left/top) helium gas and (right/bottom) adsorbed tritium distributions within the helium bubble (view perpendicular to the a-axis)

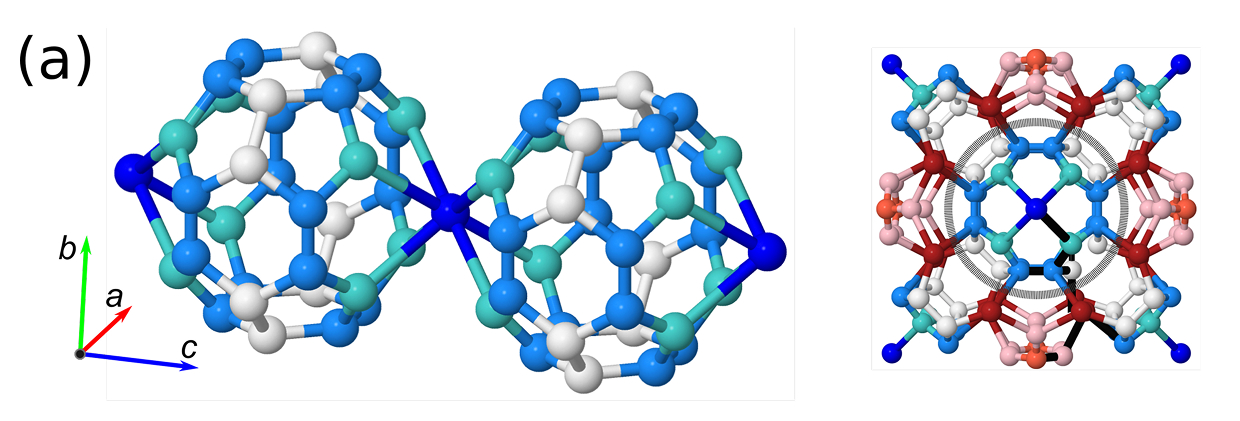

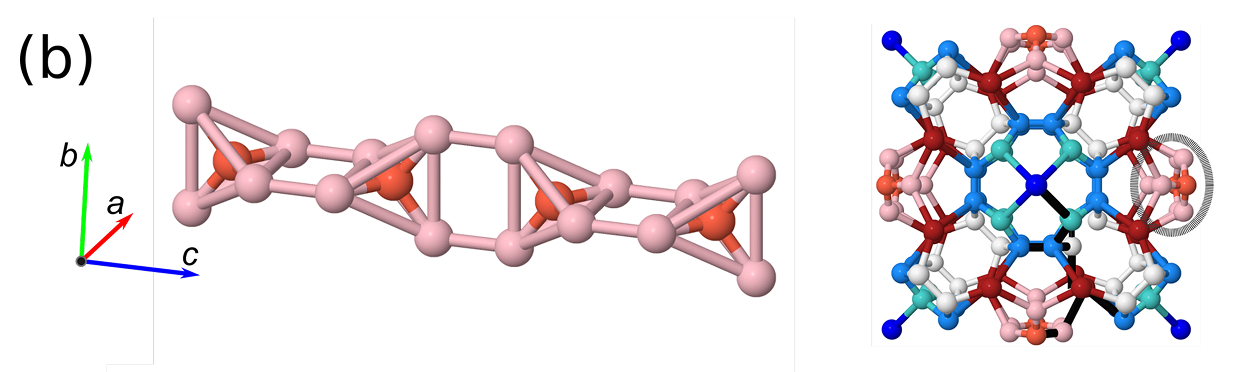

Post-irradiation studies at KIT have shown that helium bubbles in beryllides are at least ten times smaller than those formed in beryllium under the same irradiation conditions (see figure). This comparison suggests that beryllides may have a lower potential for tritium accumulation if tritium is bound in helium bubbles, as in the case of pure beryllium. These findings are crucial for the development of safe and efficient materials for future fusion reactors.

Our group investigates the grain boundaries in vanadium, a promising material for metallic membranes to separate hydrogen isotopes from other gases. There is evidence that grain boundaries in vanadium can serve as pathways for accelerated hydrogen diffusion, but also represent weak points where impurities from other elements can occur and impair membrane properties. Using ab-initio methods, we have analyzed the grain boundaries in vanadium and developed an effective interatomic interaction potential that allows both the description of grain boundaries and large-scale simulations of the hydrogen diffusion processt.

Methods

The following modeling methods are applied by our group on different space and time scales:

- Density functional theory methods (ab-initio)

- conventional molecular dynamics based on the first principles of density functional theory

- Development of interatomic interaction potentials from ab-initio data by machine learning,

- atomistic kinetic Monte Carlo simulations and

- methods of rate equations

Methods of density functional theory (ab-initio):

Our research group uses density functional theory (DFT) to study defects and transmutation-induced gases such as helium and tritium in materials. Using DFT methods, we analyze the structural relaxation of defects and precisely determine the defect formation energies. These findings are crucial for understanding material stability under irradiation and contribute to the development of resistant materials for applications in fusion and nuclear technology.

Molecular dynamics

Our research group uses molecular dynamics simulation to study the behavior of helium and tritium in beryllium and beryllides. This method makes it possible to analyze diffusion processes, the accumulation of helium and tritium in bubbles and the interactions with defects at the atomic level. Through these simulations, we gain valuable insights into microstructure development under irradiation and contribute to the optimization of materials for fusion applications.

Atomistic kinetic Monte Carlo method and cluster dynamics

Our research group uses the atomistic kinetic Monte Carlo method and cluster dynamics to study tritium accumulation in beryllium and beryllides. With this method we simulate the diffusion and release behavior of tritium after thermal loading, implantation or irradiation. This allows us to interpret experimental results on tritium release and to better understand basic mechanisms of tritium retention and migration at the microscopic level, which contributes to the development of optimized materials for fusion applications.

Our group performs the following tasks within the work package Breeding Blanket:

- Evaluation of the tritium trapping capacity of helium bubble beryllides

- Development of machine learning models for interatomic potentials in the T-Be-He system

- Evaluation of hydrogen and helium diffusion coefficients in TiBe₁₂

This work contributes to the development of materials for future nuclear fusion reactors, in particular with regard to their neutron multiplication and tritium production.

Ulba Metallurgical Plant

Unsere Zusammenarbeit mit dem Ulba Metallurgical Plant in Kasachstan hat bedeutende Fortschritte in der Entwicklung fortschrittlicher Beryllid-Materialien für Fusionsanwendungen ermöglicht. Im Rahmen dieser Partnerschaft wurden mehrere vollformatige Beryllid-Mock-up-Blöcke aus TiBe₁₂ und CrBe₁₃ erfolgreich gefertigt und zyklischen thermischen Belastungstests unterzogen. Diese Experimente simulierten die pulsierten Betriebsbedingungen, die für die DEMO-Tritiumbrutdecke vorgesehen sind, und lieferten wertvolle Erkenntnisse über die Leistungsfähigkeit und Haltbarkeit der Materialien. Diese Entwicklung stellt einen wichtigen Schritt zur Realisierung zuverlässiger und effizienter Brutdeckenkomponenten für zukünftige Fusionsreaktoren dar und wurde mit dem zweiten Europäischen SOFT Innovation Prize ausgezeichnet.

KBHF Deutschland

Unsere Zusammenarbeit mit der Karlsruhe Beryllium Handling Facility (KBHF), einem Unternehmen mit einer Lizenz zur Verarbeitung und Lagerung von Beryllium-haltigen Materialien, ermöglicht umfassende Forschungs- und Entwicklungsarbeiten auf diesem Gebiet. In enger Kooperation mit unserer Gruppe werden hier die Charakterisierung sowie die Forschung und Entwicklung an Beryllium-Pebbles durchgeführt, Beryllide mittels Heißisostatischem Pressen (Hipping) hergestellt, die Wärmeleitfähigkeit von Beryllium-Pebble-Betten gemessen und Proben für weiterführende Untersuchungen vorbereitet. Diese Arbeiten tragen wesentlich zur Weiterentwicklung von Beryllium-Materialien für Fusionsanwendungen bei.

SCK-CEN, Belgium

In cooperation with SCK CEN in Mol, Belgium, irradiation tests are currently being carried out on beryllium pebbles and newly developed beryllides. These tests take place in the BR2 material test reactor in Mol and are used to investigate the behavior of these materials under intense neutron irradiation. The irradiated samples are expected to be transported to the KIT at the end of 2025, where further post-irradiation studies will be carried out to analyze their structural and thermophysical properties in detail. This research work will make an important contribution to the qualification of beryllium materials for future fusion applications.

Culham Centre for Fusion Energy (CCFE), UK

Our group works closely with the Materials Research Facility at the Culham Centre for Fusion Energy (CCFE) in the UK. We use their advanced technologies for the preparation of FIB (Focused Ion Beam) samples from irradiated materials and for microstructural and elemental analysis using transmission electron microscopy (TEM) and atom probe tomography. This cooperation enables high-resolution investigations of material changes under irradiation and contributes significantly to the understanding and further development of materials for fusion applications.

Publications

Busch, S.; Ferrario, P. G.; Henk, A.-K.; Engelbert, A. K.; Wittek, O.; Seifert, S.; Bub, A.; Mack, C. I.; Hieronimus, B.

2026. JMIR Research Protocols, 15, Article no: e81857. doi:10.2196/81857

Wunsch, T.; Hoffmann, M.; Woll, A.

2026. QLB@BW – Eine Bestandsaufnahme der Lehrkräftebildung in Baden-Württemberg. Hrsg.: C. Sälzer, 93–114, Waxmann Verlag

Tarantini, C.; Talantsev, E. F.; Pallecchi, I.; Hänisch, J.; Tallon, J. L.; Larbalestier, D. C.

2026. Superconductor Science and Technology, 39 (2), 021001. doi:10.1088/1361-6668/ae417f

Teramae, T.; Wild, J.; Huang, J.; Chassaing, D.; Issariyapat, A.; Eusterholz, M. K.; Kariya, S.; Umeda, J.; Kondoh, K.

2026. Journal of Alloys and Compounds, 1057, 186733. doi:10.1016/j.jallcom.2026.186733

Masuda, L.; Matsumoto, R.; Takano, Y.; Walter, K.; Jung, A.; Martinelli, A.; Hänisch, J.; Iida, K.

2025, February 14. 2nd Iron-based Superconductors: Advances towards applications (IBS2app 2025), Miyazaki, Japan, February 13–15, 2025

Welz, B.; Pierotti, S.; Fitzgerald, T.; Thumberger, T.; Suzuki, R.; Watson, P.; Fuss, J.; Cordeiro da Trindade, T.; Defranoux, F.; Ferreira, M.; Naruse, K.; Loosli, F.; Gierten, J.; Wittbrodt, J.; Birney, E.

2026. Cell Genomics, Art.Nr: 101164. doi:10.1016/j.xgen.2026.101164

Ivanov, V.; Markowz, G.; Schmitt, F.; Pauleikhoff, J.

2025. CBR Sustainability Partners. doi:10.5445/IR/1000190908

Baruah, S.; Popov, R.; Hanisch, J.; Matias, V.; Bagrets, N.; Selskij, V.; Holzapfel, B.

2025, September 22. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Baruah, S.; Singhal, S.; Dam, M.; Jelden, P.; Hänisch, J.; Börner, M.; Arndt, T.; Gerrit Korvink, J.; Holzapfel, B.

2025, June 30. 1st Microscale NMR and MRI conference (2025), Ettlingen, Germany, June 29–July 2, 2025

Masuda, L.; Moorinaga, K.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, October 13. Materials Research Meeting (2025), Yokohama, Japan, December 8–13, 2025

Baruah, S.; Popov, R.; Hänisch, J.; Matias, V.; Bagrets, N.; Nast, R.; Singhal, S.; Korvink, J.; Barth, C.; Ballarino, A.; Holzapfel, B.

2026. IEEE transactions on applied superconductivity, 36 (5), Article no: 6602405. doi:10.1109/TASC.2026.3661464

Masuda, L.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, September 23. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Jamatia, T.; Pechancová, V.; Paul, D.; Buchgeister, J.; Baumann, M.; Ersoy, H.; Erakca, M.; Saha, P.

2026. iScience, Article no: 115110. doi:10.1016/j.isci.2026.115110

Zhong, S.; Sui, P.; Holtappels, P.; Navarrete, A.; Li, F.; Dittmeyer, R.

2025. Chemical Engineering Journal, 509, Art.-Nr.: 161119. doi:10.1016/j.cej.2025.161119

Laborgne, P.; Wieczorek, W.; Wendeberg, E.

2026. Book of Abstracts from the Urban Europe Research Alliance (UERA) Conference 2026. Ed.: E Lissandrello, 34–35, Aalborg University Open Publishing