Head of Deparment: Dr. Michael Rieth

Our research and development work is part of large-scale research and makes an important contribution to energy research at national and European level. As a partner in the Helmholtz Association's energy program and a member of the EUROfusion large-scale research project, we are actively shaping the future of nuclear fusion.

Focus

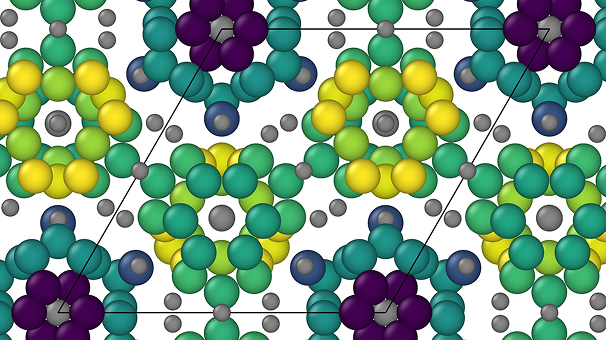

We develop structural and functional materials that can withstand extreme conditions. These include high temperatures and heat fluxes, as well as high-energy neutron radiation in combination with mechanical, chemical, or time-critical loads. The material properties are tailored by us for each specific application case. In this way, we open up new applications and areas of use in the field of energy conversion. Typical examples include components of a fusion power plant, such as plasma-facing components (divertor), heat exchangers (blanket), and neutron multipliers (tritium breeding elements).

Competence

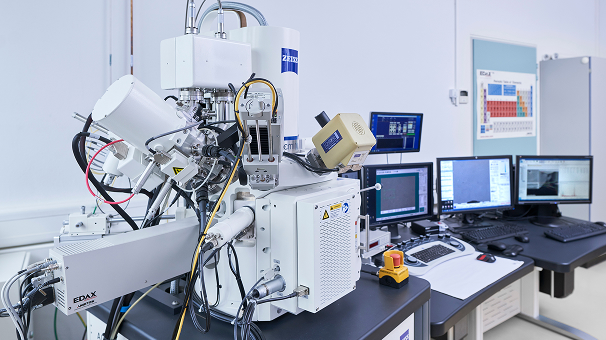

Our research is application-oriented and, above all, takes place under the aspects of large-scale research. Therefore, alongside sustainability and cost-effectiveness, the focus is particularly on the use of industrial production, forming, joining, and manufacturing technologies. Starting from an idea, our materials development encompasses theoretical modelling, thermodynamic and thermo-mechanical simulations, production in the laboratory and on an industrial scale, experimental characterization of all relevant properties, microstructural and chemical analyses, the manufacturing of prototypes (semi-finished products and mockups), as well as component testing under the respective operating conditions. Our goal is to provide novel materials, including the materials technology process parameters and key characteristics required for production and component manufacturing.

Network

Despite our focus on materials for very specific applications, the boundary conditions, requirements, and properties to be considered are very complex and diverse. So not all necessary investigations and experiments can be carried out within our department. Therefore, we collaborate closely with a variety of partners from KIT, industry, and other research institutions both domestically and internationally. In particular, the characterization and testing of prototypes requires access to large-scale facilities, such as test reactors for neutron irradiation: : HFIR, BR2, or experimental setups for the investigation of plasma-material interactions: HELOKA, ASDEX, GLADIS, JUDITH & JULE-PSI.

Automated modeling and validation

GroupPublicationslist

Karlsruher Institut für Technologie. KIT (Ed.)

2026. Karlsruher Institut für Technologie (KIT)

Dwivedi, M.

2026. Technische Informationsbibliothek Hannover. doi:10.34657/30076

Amalfitano, D.; Metzger, A.; Autili, M.; Fulcini, T.; Hey, T.; Keim, J.; Pelliccione, P.; Scotti, V.; Koziolek, A.; Mirandola, R.; Vogelsang, A.

2026. ACM Transactions on Software Engineering and Methodology. doi:10.1145/3788879

Albajar, F.; Sanchez, F.; Alberti, S.; Avramidis, K.; Bader, M.; Bin, W.; Braunmueller, F.; Bruschi, A.; Cavinato, M.; Chelis, I.; Cindric, K.; Garavaglia, S.; Carannante, G.; Casal, N.; Chanois, J.; Dall’Acqua, D.; Darbos, C.; Ell, B.; Fasel, D.; Frei, M.; Gantenbein, G.; Genoud, J.; Goodman, T.; Granucci, G.; Hogge, J.-P.; Illy, S.; Ioannidis, Z.; Jelonnek, J.; Jin, J.; Jubany, E.; Legrand, F.; Leggieri, A.; Lievin, C.; Lescure, C.; Picas, O.; Raval, B.; Rzesnicki, T.; Romano, A.; Romanova, A.; Savoldi, L.; Siravo, U.; Thumm, M.; Tigelis, I.; Timperi, F.; Team, the F. O.

2025, October. 30th IAEA Fusion Energy Conference (FEC 2025), Chengdu, China, October 13–18, 2025

Kettner, C.; Poppenborg, R.; Hermann, B.; Haidn, O.; Stein, T.

2025. Sportwissenschaft: Vielfalt und Nachhaltigkeit!? Abstracts zum 27. Hochschultag der Deutschen Vereinigung für Sportwissenschaft; Münster, 16.-19.09.2025; Strauß, B., Tietjens, M., van Meurs, E. & Henning, L. (Hrsg.)

Roth, C.; Maier, L.; Abel, B.; Roigk, P.; Rapp, K.; Schmidberger, O.; Bongartz, M.; Maier, S.; Wirth, I.; Metz, B.; Immel, D.; Finger, B.; Schölch, S.; Büchele, G.; Deuster, O.; Koenig, H.-H.; Gottschalk, S.; Dams, J.; Micol, W.; Bauer, J. M.; Wensing, M.; Benzinger, P.

2024. BMC geriatrics, 24 (1), Art.: 720. doi:10.1186/s12877-024-05277-7

Maier, L.; Benzinger, P.; Abel, B.; Roigk, P.; Bongartz, M.; Wirth, I.; Cuvelier, I.; Schölch, S.; Büchele, G.; Deuster, O.; Bauer, J.; Rapp, K.; Ullrich, C.; Wensing, M.; Roth, C.

2024. European geriatric medicine, 15 (5), 1369–1382. doi:10.1007/s41999-024-01027-5

Qiu, Y.; Álvarez, I.; Ambrožič, K.; Berry, T.; Bieńkowska, B.; Chohan, H.; Čufar, A.; Dworak, D.; Lopez-Revelles, A.; Lopez, V.; Mota, F.; Martinez-Echevarria, M.; Piotrowski, T.; Serikov, A.; Stankunas, G.; Tidikas, A.; Taling, L.; Tracz, G.; Wiącek, U.; Ansorge, M.; Jimenez-Rey, D.; Mendoza, E.; Malec, J.; Martínez-Serrano, J.; Akbaş, S.

2025. 30th IAEA Fusion Energy Conference (FEC 2025), Vienna, Austria, October 13–18, 2025

Sanchez Ortiz, G.; Löberbauer, M.; Andrić-Tomašević, N.; Mandic, O.; Pavelić, D.; Demir, V.; Keys, P. W.; Meijers, M. J. M.; Rugenstein, J. K. C.

2026. Journal of Hydrology: Regional Studies, 64, Art.-Nr.: 103214. doi:10.1016/j.ejrh.2026.103214

Zipperling, D.; Ott, L.; Vössing, M.; Kühl, N.

2026. Business & Information Systems Engineering, 68 (1). doi:10.1007/s12599-026-00986-2

Stakhanova, A.; Gabrielli, F.; Sanchez Espinoza, V. H.; Pauli, E.-M.; Hoefer, A.

2025. Nuclear Technology, 1–18. doi:10.1080/00295450.2025.2544372

Schußmann, M. G.; Hirschberg, V.; Wilhelm, M.; Wagner, M. H.

2026. Macromolecular Rapid Communications, Art.-Nr.: e00930. doi:10.1002/marc.202500930

Polly, R.; Bagus, P.

2026. Inorganic Chemistry. doi:10.1021/acs.inorgchem.5c04776

Salehian, S.; Mora, J. M.; Li, H.; Esau, D.; Lee, M. H.; Weber, A.; Chuang, P.-Y. A.

2026. Applied Sciences, 16 (3), Art.-Nr.: 1497. doi:10.3390/app16031497

Lacerda de Oliveira Campos, B.; Dutzi, J.; Campos Fraga, M. M.; Vadarlis, A. A.; Sauer, J.

2026. Chemical Engineering Journal, 530, Art.-Nr.: 173614. doi:10.1016/j.cej.2026.173614

Pomella Lobo, T.; Maione, I. A.

2025. 30th IAEA Fusion Energy Conference (FEC 2025), Vienna, Austria, October 13–18, 2025

Sperrle, A.

2025, November 12

Yildiz, Z.

2026. Proceedings of the 2026 CHI Conference on Human Factors in Computing Systems (CHI ’26), April 13–17, 2026, Barcelona, Spain, Association for Computing Machinery (ACM). doi:10.1145/3772318.3790600

Fuchs, S.; Debus, C.; Novack, P.; Goetz, M.

2026. doi:10.5445/IR/1000190844