The special thermophysical properties of liquid metals enable the transfer of high heat flows at high temperatures. This opens up new possibilities for energy conversion, storage and high-temperature process technology in general.

The IAM-AWP's Liquid Metal Technology Group contributes to the research and development programs in Helmholtz Energy, focusing on material behavior towards liquid metals, in the absence or presence of a mechanical load; instruments and methods to control non-metals dissolved in liquid metals; and coatings for use in liquid metals.

Material behavior towards liquid metals

Experimental investigations include corrosion tests on metallic materials, predominantly steels, in stationary or flowing liquid metals. Particular attention is paid to quantifying the material damage and determining the corrosion kinetics. The aim is generalization by means of corrosion mechanisms, in accordance with the observations and as a basis for their model description. Experiments on interactions between corrosion and simultaneous mechanical stress on the material extend the database available for assessing the material behavior in the application. In view of the particular influence of oxygen dissolved in the liquid metal on the speed or the form of corrosion that occurs, it is possible to measure or specifically influence dissolved oxygen for the majority of the test systems used.

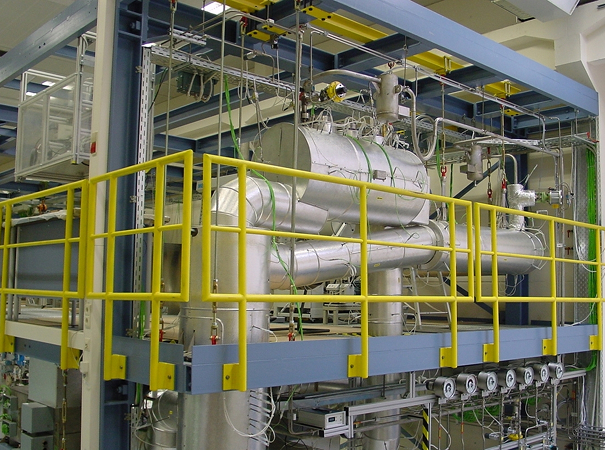

Liquid metal loop CORRIDA for corrosion studies in oxygen-containing flowing lead-bismuth (Pb45Bi) at up to 550 °C.

CORRIDA loop (Pb45Bi)

CORRIDA is a loop operated with eutectic lead bismuth (Pb45Bi), with a circulating mass of about 1000 kg, at a mass flow rate of usually 5.3 kg/s. Oxygen sensors in five selected positions enable the monitoring of oxygen dissolved in the liquid metal, the content of which is influenced by the exchange with a quasi-static gas atmosphere. The maximum temperature in the hot section of the loop can be up to 550 °C.

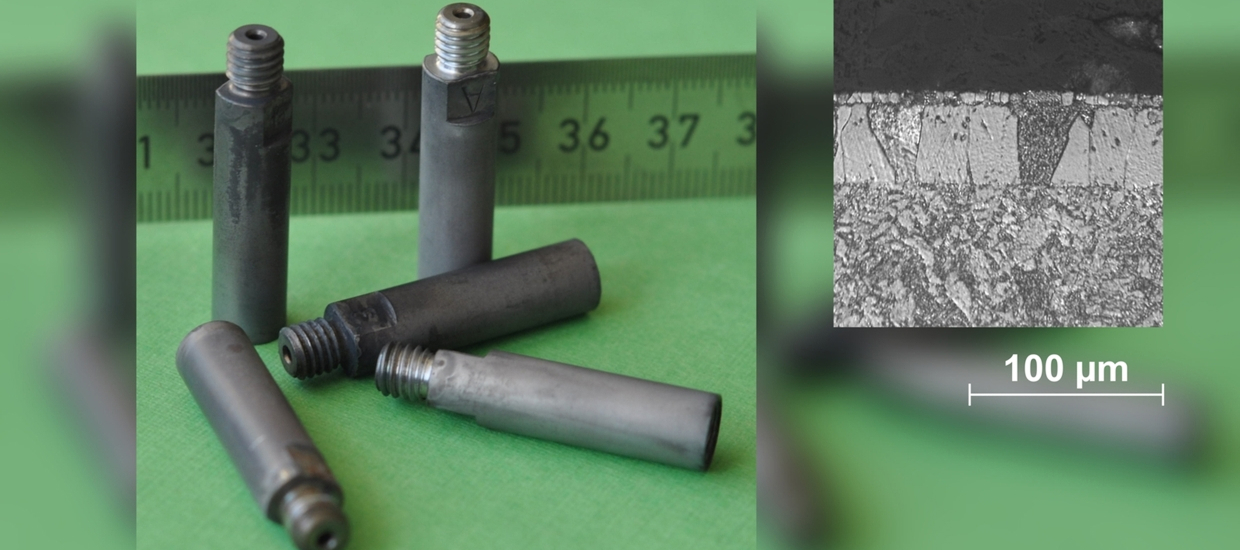

In the CORRIDA loop, corrosion tests are carried out in oxygen-containing flowing lead bismuth on cylindrical material samples, usually with a diameter of 8 and a length in the region of 30 mm. The two test sections in the hot part of the loop can each hold up to 18 of the standard samples simultaneously.

In addition to long-term corrosion data (up to 20,000 h for individual samples), the operation of CORRIDA has contributed significantly to the development of an automated oxygen control system for liquid metals and the qualification of electrochemical oxygen sensors for continuous operation, as well as providing valuable insights into the precipitation behavior of dissolved steel components in a non-isothermal liquid metal cycle.

Steel capsule with a filling volume of 70 ml liquid metal for corrosion tests on cylindrical samples with a diameter of 6 mm at up to 550 °C.

Corrosion in static liquid metal

The exposure of material samples to static liquid metal in smaller test apparatuses is particularly suitable for determining the general corrosion behavior as part of material development programs. The use of a ceramic crucible to hold the liquid metal avoids contamination beyond the dissolving components of the samples or the latter can be specifically adjusted and its influence investigated. The crucible is placed inside an externally heated steel capsule, which is equipped with instrumentation for internal temperature measurement, gas inlet and outlet, and monitoring of oxygen dissolved in the liquid metal. Automated control of the oxygen content is carried out by integrating the capsule into measuring stations equipped for this purpose in the laboratory.

Such steel capsules can be adapted to the number of samples to be tested simultaneously, their size and the temperature at which they are to be tested, up to a capacity of around 1000 ml of liquid metal. The achievable temperature depends on the material of the capsule and the selected heating and thermal insulation. The behavior of steels and nickel-based alloys in liquid lead, lead-bismuth eutectic (Pb45Bi) or tin has been investigated using such capsules, at temperatures up to 750 °C.

Steel capsule for holding the sample and liquid metal for creep tests at up to 650 °C in the CRISLA test stand.

Creep and creep rupture in liquid metal at rest

In the CRISLA test rig, material samples, primarily steels, are tested for creep and creep rupture under simultaneous stress from liquid metal at rest. The sample and liquid metal are contained in a closed steel capsule. A flexible bellows integrated into the lid is used to apply a static tensile force to the sample anchored in the base of the capsule and to transfer the deformation to the outside. The capsule is equipped with a gas inlet and outlet as well as an oxygen sensor to specifically influence the oxygen dissolved in the liquid metal. The maximum operating temperature is 650 °C.

The test stand has 8 places where such capsules can be mechanically loaded, five of which are equipped with the gas supply and measurement and control technology required for automated oxygen control.

In CRISLA, the creep and creep rupture of steels in lead and eutectic lead-bismuth (Pb45Bi) are investigated in particular. The basis for the evaluation of the experiments is provided by comparative experiments in stagnant air carried out in a capsule similar to the one used for the experiments with liquid metal, with the same load task and deformation measurement.

The recently completed test facility combines a servo-electric dynamic testing machine for tensile loads of up to 50 kN with a steel capsule for holding 750 ml of liquid sodium next to the tested material sample. A circulation-cooled inert gas chamber (argon) with a volume of 230 l integrated into the test chamber of the machine prevents contact of hot sodium with oxygen or moisture in the event of failure of parts of the steel capsule during the tests. The force is introduced into the chamber and the test capsule via diaphragm or bellows; the elongation of the part of the load string containing the sample is recorded via the elongation of the bellows on the capsule. The system is currently designed for test temperatures of up to 550 °C; an expansion to 750 °C is planned.

Instruments and methods for controlling dissolved non-metals

Non-metals dissolved in the liquid metal can have a favorable or unfavorable effect on its properties. Dissolved non-metals can trigger material transformations in the liquid metal or arise as their product. In all these cases, the measurement of the concentration and the targeted addition or removal of a non-metal are important.

For metallic structural materials in contact with a liquid metal, the type and extent of material damage is determined not least by the amount of oxygen dissolved in the liquid metal. This is measured using electrochemical sensors with a solid electrolyte based on zirconium dioxide. Oxygen is added or removed depending on the indicated deviation from the target value, e.g. by mass transfer with a gas flow with variable oxygen partial pressure. This method is particularly suitable for liquid lead and lead-bismuth alloys and has been developed as an automated oxygen control for these liquid metals. It is directly transferable to other liquid metals with low to moderate oxygen affinity.

Hydrogen can be produced via high-temperature reactions, for which liquid metals are also suitable as a reaction medium. One process that is of particular importance for fusion technology and research is the production of the hydrogen isotope tritium through the reaction of neutrons with lithium. The hydrogen sensors currently being developed for use in liquid lithium work according to the electrochemical principle with a liquid salt mixture as the electrolyte.

The targeted modification of properties on the surface of a structural material can extend its service life in the event of external stresses acting on the material. The change that can be achieved by creating a layer of a second material is the most challenging. In addition to the function, the adhesion of the coating to the substrate in particular must be guaranteed and must be permanently maintained under the stresses to which the composite is subjected when used.

For metallic materials in the presence of liquid metals, corrosion protection is generally of paramount importance. If there is a minimum amount of oxygen dissolved in the liquid metal, corundum (a-Al2O3) or coatings that form this oxide are particularly suitable.

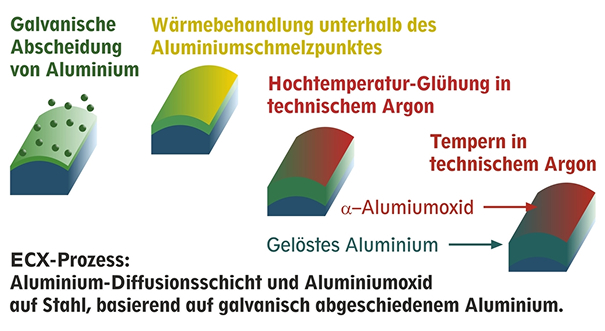

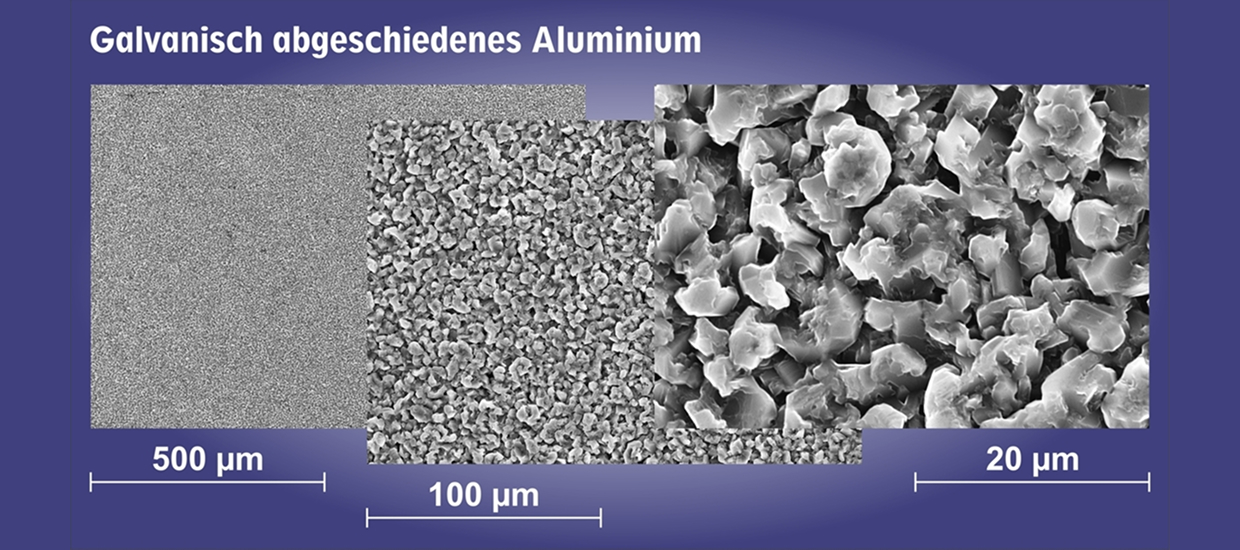

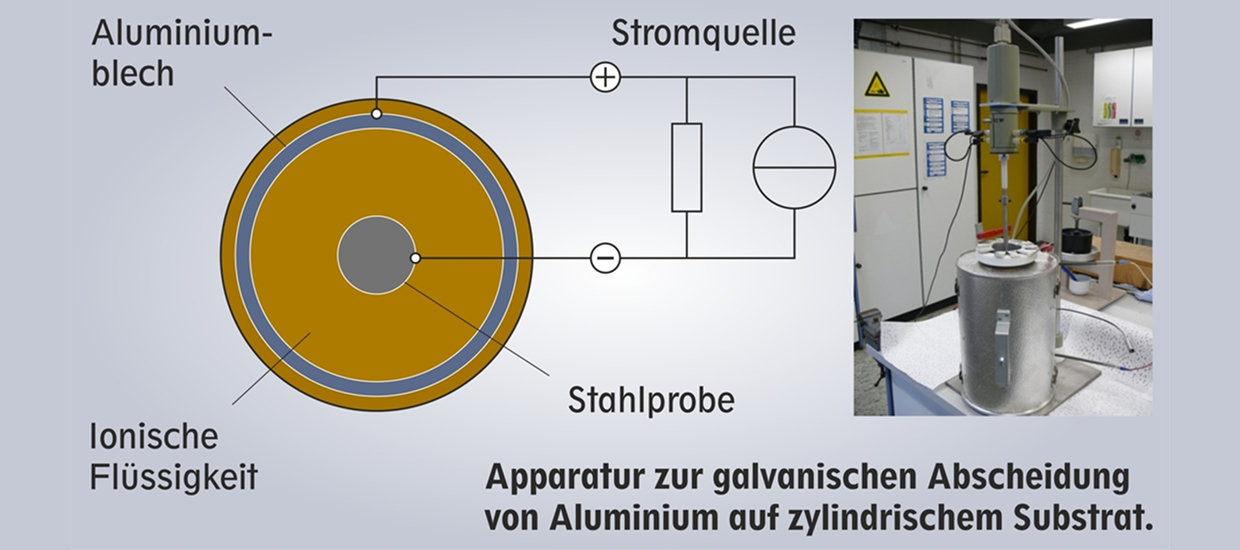

Currently developed coatings for steel are based on the galvanic deposition of aluminum from an ionic liquid and a three-stage heat treatment, during which the aluminum dissolves in the zone near the surface of the steel and aluminum oxide grows on the surface. The oxygen required for this is supplied by the gas atmosphere in the annealing furnace.

The work is related to the development of the fusion reactor, for which certain components must be protected against corrosion by a liquid lithium-lead alloy. At the same time, the surface must be electrically non-conductive and, in particular, the passage of tritium through the component wall must be reduced. Aluminum oxide can fulfill all three functions.