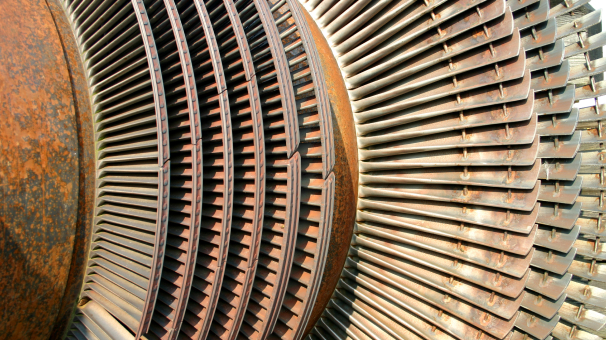

The Gas Corrosion Group develops new alloy systems for high-temperature materials using thermodynamic modelling. We carry out corrosion tests in different oxidizing gases at 1000 °C and above, as well as advanced microstructure investigations. By developing materials that are stable under extreme conditions, our research contributes to increasing the efficiency of high-temperature energy conversion.

Group

The Liquid Metal Technology Group deals with the interactions between liquid metals and materials. We also develop methods for measuring and controlling non-metals dissolved in liquid metals as well as material coatings for use in liquid metals. With the qualification and targeted improvement of materials, we are opening up new fields of application for liquid metals.

GroupThe availability of materials that are compatible with the operating conditions is a prerequisite for the reliable and economical implementation of processes in industrial plants and machines. Undesirable interactions between the materials and the process environment as well as advantageous material behaviour need to be understood on a mechanistic level and quantified. When established concepts reach their limits, new approaches must be developed, including new material classes or material composites. Our tools include thermodynamic modelling of alloy systems, testing equipment adapted to the process-specific loads, and modern materialography. Our work is currently focussed on gas corrosion and material interactions with liquid metals.

Publication

Busch, S.; Ferrario, P. G.; Henk, A.-K.; Engelbert, A. K.; Wittek, O.; Seifert, S.; Bub, A.; Mack, C. I.; Hieronimus, B.

2026. JMIR Research Protocols, 15, Article no: e81857. doi:10.2196/81857

Wunsch, T.; Hoffmann, M.; Woll, A.

2026. QLB@BW – Eine Bestandsaufnahme der Lehrkräftebildung in Baden-Württemberg. Hrsg.: C. Sälzer, 93–114, Waxmann Verlag

Tarantini, C.; Talantsev, E. F.; Pallecchi, I.; Hänisch, J.; Tallon, J. L.; Larbalestier, D. C.

2026. Superconductor Science and Technology, 39 (2), 021001. doi:10.1088/1361-6668/ae417f

Teramae, T.; Wild, J.; Huang, J.; Chassaing, D.; Issariyapat, A.; Eusterholz, M. K.; Kariya, S.; Umeda, J.; Kondoh, K.

2026. Journal of Alloys and Compounds, 1057, 186733. doi:10.1016/j.jallcom.2026.186733

Masuda, L.; Matsumoto, R.; Takano, Y.; Walter, K.; Jung, A.; Martinelli, A.; Hänisch, J.; Iida, K.

2025, February 14. 2nd Iron-based Superconductors: Advances towards applications (IBS2app 2025), Miyazaki, Japan, February 13–15, 2025

Welz, B.; Pierotti, S.; Fitzgerald, T.; Thumberger, T.; Suzuki, R.; Watson, P.; Fuss, J.; Cordeiro da Trindade, T.; Defranoux, F.; Ferreira, M.; Naruse, K.; Loosli, F.; Gierten, J.; Wittbrodt, J.; Birney, E.

2026. Cell Genomics, Art.Nr: 101164. doi:10.1016/j.xgen.2026.101164

Ivanov, V.; Markowz, G.; Schmitt, F.; Pauleikhoff, J.

2025. CBR Sustainability Partners. doi:10.5445/IR/1000190908

Baruah, S.; Popov, R.; Hanisch, J.; Matias, V.; Bagrets, N.; Selskij, V.; Holzapfel, B.

2025, September 22. 17th European Conference on Applied Superconductivity (EUCAS 2025), Porto, Portugal, September 21–25, 2025

Baruah, S.; Singhal, S.; Dam, M.; Jelden, P.; Hänisch, J.; Börner, M.; Arndt, T.; Gerrit Korvink, J.; Holzapfel, B.

2025, June 30. 1st Microscale NMR and MRI conference (2025), Ettlingen, Germany, June 29–July 2, 2025

Masuda, L.; Moorinaga, K.; Matsumoto, R.; Takano, Y.; Martinelli, A.; Walter, K.; Jung, A.; Hänisch, J.; Iida, K.

2025, October 13. Materials Research Meeting (2025), Yokohama, Japan, December 8–13, 2025