Project 5: High-temperature oxidation behaviour of ceramic coatings based on polymer-derived ceramic nanocomposites

Dr. Nils-Christian Petry (1st cohort)

Dr. Nils-Christian Petry (1st cohort)

M.Sc. Büsra Prill (2nd cohort)

Supervisors: PD Mathias Galetz, Prof. Bronislava Gorr

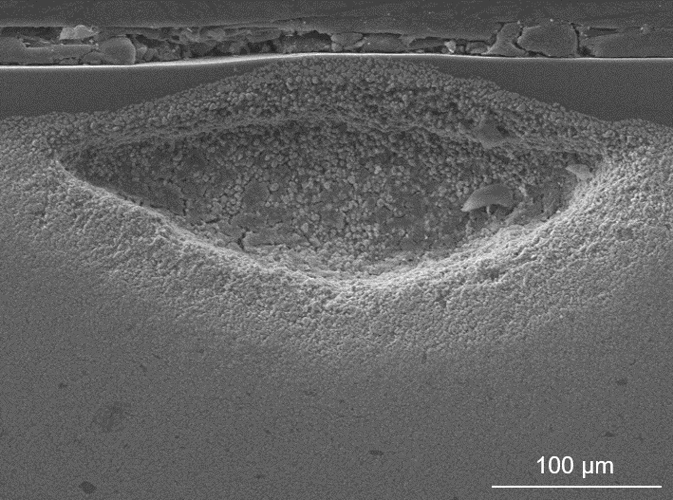

In project 5.2 coatings and especially filler materials for PDC-NCs are designed to improve the high temperature oxidation behavior (T ≥ 1300 °C) and phase stability of PDC-NCs. As a main goal, the thermal conductivity of Si-based PDC-NC is to be reduced by the filler materials. As filler materials, different high entropy oxides with the general formula A6B2O17 (A = Zr, Hf; B = Nb, Ta) will be synthesized. In a first step phase and chemical composition as well as morphology of the synthesized filler materials are examined after high temperature heat treatment to identify the best candidates. Upon selection of the filler material, thermal barrier coatings with additional filler material will be fabricated together with the TUD and characterized for application temperatures above 1200 °C.

In parallel, the oxidation behavior of SiAlOC bond coats on Mo-Si-Ti and Mo-Si-Cr will be investigated for increased oxidation stability and adhesion of the PDC-NC based TBCs. The influence of the addition of reactive elements to such coatings to achieve excellent oxidation protection of the substrate will be investigated.