Project 3: Microstructural and Chemical Developments at the Interfaces between MoSiTi/Bond Coat/PDC (Polymer Derived Ceramics)

Dr. Nathalie Thor (1st cohort)

Dr. Nathalie Thor (1st cohort)

M.Sc. Ingrit Sisilia Rosari Nurak (2nd cohort)

Supervisors: Prof. Astrid Pundt, TT.Prof. Yolita Eggeler

The efficiency of transport, industrial and chemical processes increase with temperature. Therefore, structural materials for engine parts, plant components, burners etc. with improved high- and ultrahigh-temperature capability are required [1]. The main idea of this project is to develop novel material combinations to achieve operating temperatures well above 1300 °C in internal combustion engines (ICEs) and hemical plants (CPs). The key idea remains the combination of Polymer-Derived Ceramics (PDC) as top coat with bulk metallic/intermetallic alloys as substrate such as MoSiTi or MoSiCr.

PDC nanocomposite coatings can offer self-healing capability in addition to excellent oxidation and corrosion resistance [2]. They exhibit ultra-high temperature properties in terms of melting points, phase stability and resistance against decomposition. During the first cohort, the main focus was on the process optimization of ceramic bulk materials via microstructural analysis. The microstructure of polymer-derived ceramics nanocomposites (PDC-NCs) as a bulk material based on Si(M)CX with M= Hf, Ta, and X= B, O, N were successfully described by XRD, SEM (EDX) and for selected regions by HRTEM including SAED and EDS [3,4].

In the second cohort, the initial sample preparation strategy for electron transparent thin TEM samples of the metal/ceramic or multilayer/ceramic interfaces in various composite materials will be extended for high resolution imaging and local chemical analysis. After sample preparation, the materials are first imaged via SEM and conventional TEM techniques, followed by high resolution TEM to explicitly study the interface structures or local nanocrystalline precipitates. Depending on the specific question addressed, HR-STEM imaging (with the aid of a Cs corrector) will allow chemical variations to be imaged down to the atomic column level, to identify segregation at interfaces or local enrichment of specific elements in the vicinity of dislocations cores.

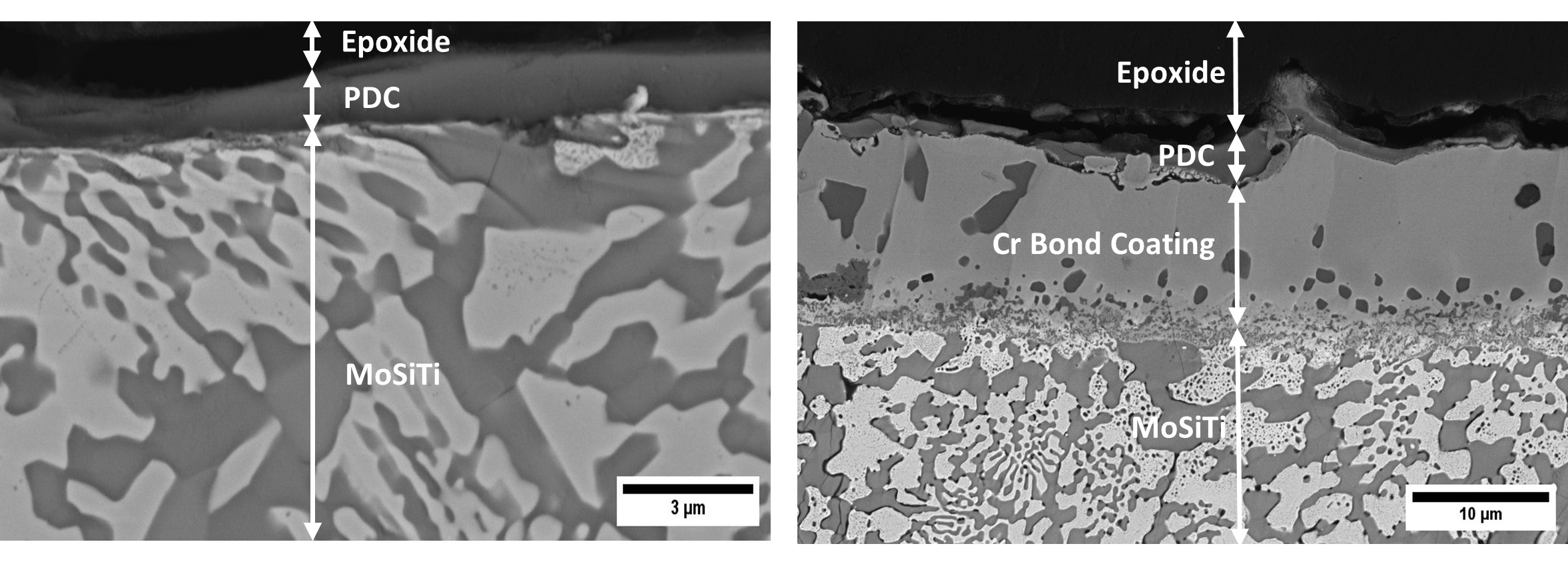

The figure shows the cross section of two different samples, one sample with bond coating and the other sample without bond coating.

SEM-BSE image of MoSiTi-PDC (left) and MoSiTi-Cr-PDC (right) interfaces

[1] Belmonte, M. (2006): Advanced ceramic materials for high temperature applications. Advanced engineering materials, 8(8), 693-703. https://doi.org/10.1002/adem.200500269

[2] Yuan, J., Galetz, M., Luan, X. G., Fasel, C., Riedel, R., & Ionescu, E. (2016): High-temperature oxidation behavior of polymer-derived SiHfBCN ceramic nanocomposites. Journal of the European Ceramic Society, 36(12), 3021-3028. https://doi.org/10.1016/j.jeurceramsoc.2015.12.006

[3] Thor, N., Bernauer, J., Petry, N. C., Ionescu, E., Riedel, R., Pundt, A., & Kleebe, H. J. (2023): Microstructural evolution of Si(HfxTa1-x)(C)N polymer-derived ceramics upon high-temperature anneal. Journal of the European Ceramic Society, 43(4), 1417-1431. https://doi.org/10.1016/j.jeurceramsoc.2022.11.060

[4] Thor, N., Winkens, G., Bernauer, J., Petry, N. C., Beck, K., Wang, J., Schwaiger, R., Riedel, R., Kolb, U., Lepple, M., & Pundt, A. (2024): Microstructure Characterization and Mechanical Properties of Polymer‐Derived (HfxTa1‐x)C/SiC Ceramic Prepared upon Field‐Assisted Sintering Technique. Advanced Engineering Materials. https://doi.org/10.1002/adem.202301841