Project 7: High-temperature oxidation behaviour of ceramic coatings based on polymer-derived ceramic nanocomposites

M.Sc. Katharina Beck (1st cohort)

M.Sc. Katharina Beck (1st cohort)

M.Sc. Lukas Korell (2nd cohort)

Supervisors: PD Mathias Galetz, Prof. Martin Heilmaier, Prof. Bronislava Gorr

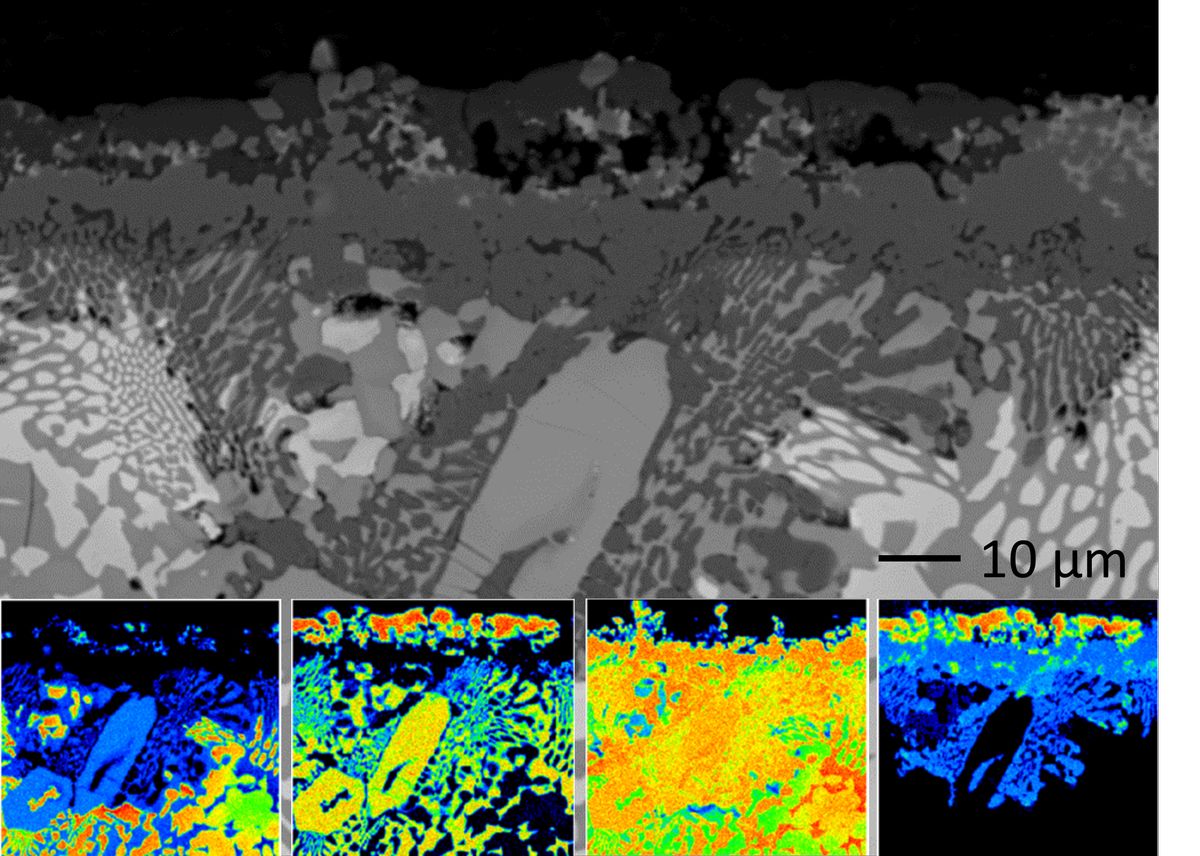

Industrial high-temperature environments are characterized by a mixture of different reactive species, usually causing the superimposition of complex corrosion attacks. A particularly severe attack is induced by deposits of solid or liquid salts on the surface of components. These deposits usually are the result of impurities in combustion atmospheres. Oxygen, sulphur, calcium, and sodium are of primary importance due to their ability to form sulphur dioxide, sulphur trioxide or sulphates. Corrosion processes involving salts, such as sulphates, are known as hot corrosion, with a distinction between type I and type II hot corrosion, depending on the temperature range. While being thoroughly investigated for Ni-based alloys, these mechanisms have barely been researched for refractory metal based alloy systems. It has been generally assumed that SiO2 layers protect the subjacent material against hot corrosion.

Project 7.1 investigated the oxidation as well as the hot corrosion type I and type II hot corrosion behavior of Mo-Si-Ti-(B) alloys. For the latter, refractory bulk materials with Na2SO4 deposits were exposed to controlled SO2/SO3-containing gas atmospheres. The alloys showed a combination of MoO3 evaporation, dissolution and reprecipitation as well as the selective oxidation of Moss over the silicide phases. Building upon this, protective layer concepts such as the application of metallic and intermetallic layers via pack cementation were developed and their protective properties were proven in additional oxidation and hot corrosion experiments.

In project 7.2 the interesting fundamental hot corrosion mechanism of Mo-based alloys will be further developed. The objectives are to observe the development of the corrosion rate over the temperature and to determine the temperatures regimes (similar to type I and type II for Ni-base) as well as temperature ranges which promote degradation mechanisms of pesting and hot corrosion. In addition, tests with varying salts such as NiSO4 and CaSO4 will be conducted. Diffusion coatings on Mo-Si-Ti showed an enhanced resistance in hot corrosion, but also a high dependence on the Mo-content of the alloy underneath. Thus, the influence of the Mo-content on the corrosion will be examined by the investigation of different Mo-Si-Ti-(B) alloys. Another task will be the optimization of the bond coat composition beyond the chemical restrictions of diffusion coatings.

During project 7.1 as well as 7.2, projects 8 and 10 provide the required Mo-base alloys, utilizing the results of the corrosion experiments for further improvement. Projects 3 and 11 help to validate some of the obtained results. Projects 2 and 6 receive aluminized samples for further experiments.