MatCom-ComMat: Materials Compounds from Composite Materials for Applications in Extreme Conditions

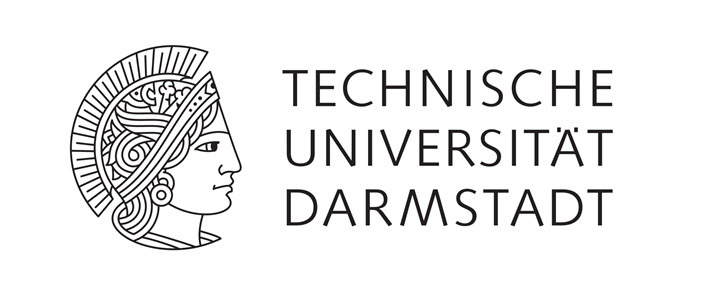

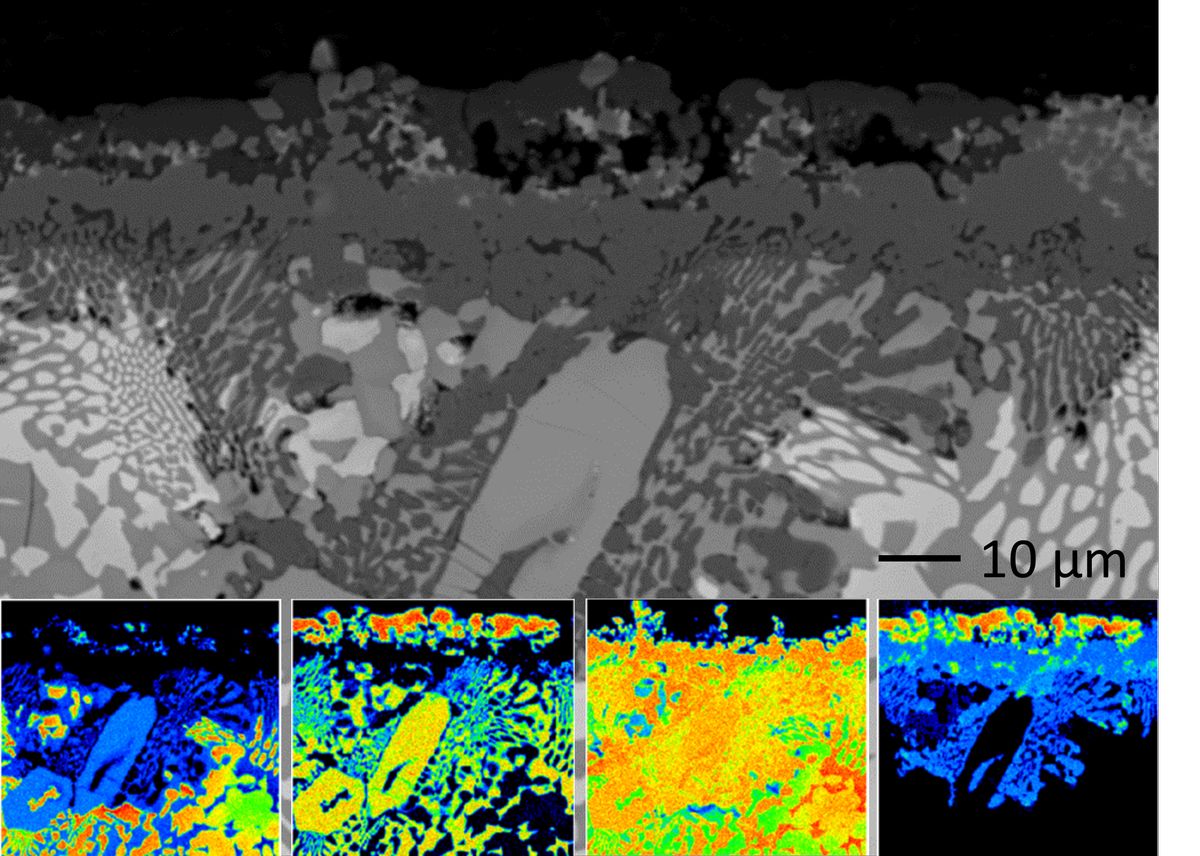

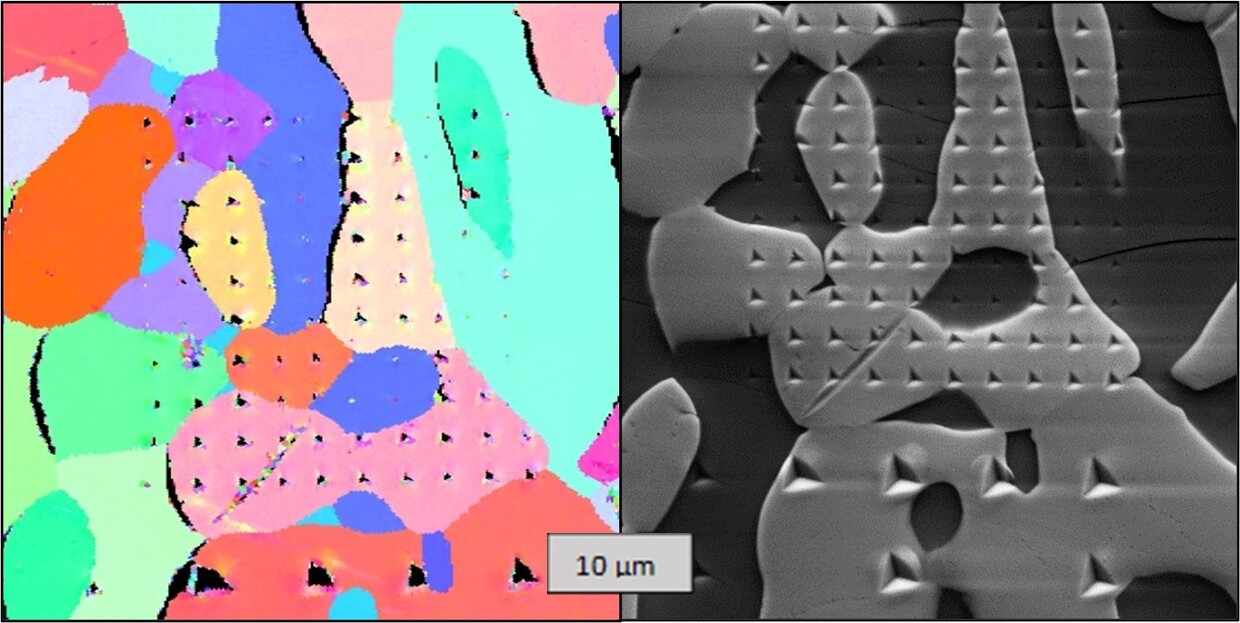

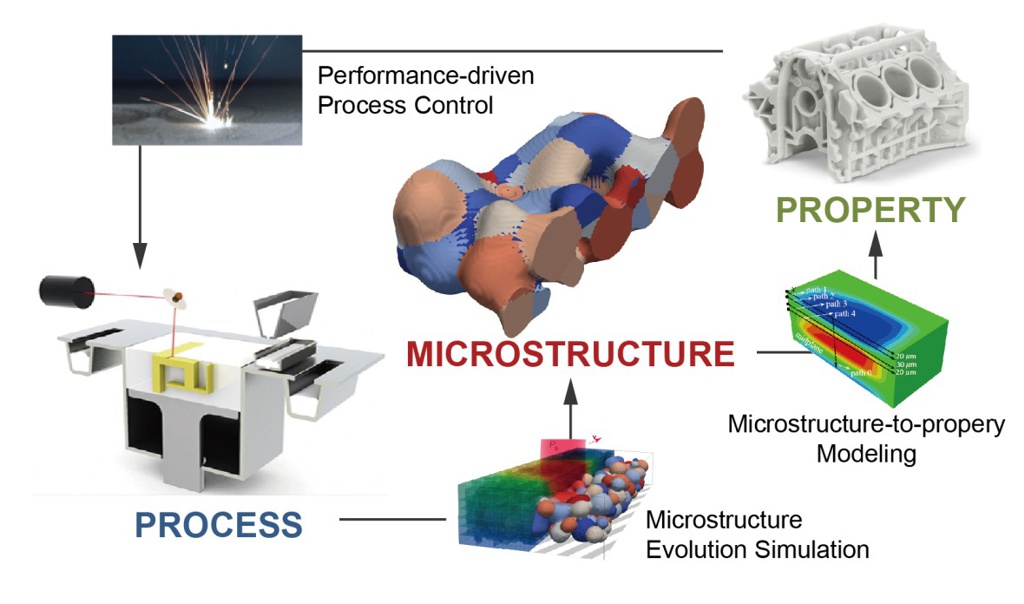

The main scope of the RTG relates to the development, characterization and modelling of novel, revolutionary multi-phase composite systems capable of withstanding temperatures substantially beyond 1300°C and harsh environmental conditions (e.g., oxidative, corrosive, erosive atmospheres) as far as mechanical behaviour, environmental resistance and durability are concerned. This will be achieved via a materials combination consisting of metallic/intermetallic alloys based on refractory metal silicide systems (e.g. Mo-Si-B-X, X = Nb, Fe, Ti, Hf…) as substrates and polymer-derived ceramic nanocomposites based on Si(M)CY (M = B, Zr, Hf and Y = O, N) as materials of choice for graded coatings. The metallic/intermetallic alloys may provide adequate deformability and toughness at ambient temperatures combined with excellent high-temperature microstructural stability and creep resistance, whereas the graded polymer derived ceramic nanocomposite coatings will also offer self-healing capability in addition to extremely low intrinsic thermal conductivities and excellent stability in aggressive operation conditions, respectively. Beside their unique property combinations, the two materials classes are highly attractive because of the possibility to adjust their coefficients of thermal expansion to perfectly match one another and consequently to keep thermomechanical stresses in the target multi-layered systems at a minimum. This may give rise to an extended lifetime of components in foreseen application.

Projects

- Project 1: Single-source precursor synthesis of ceramic nanocomposites for (ultra)high-temperature applications

- Project 2: Preparation of ceramic coatings based on ultrahigh-temperature ceramic nanocomposites (UHTC-NCs) from precursors

- Project 3: Characterization of materials compounds from composite materials

- Project 4: Thermomechanical properties of ceramic-nanocomposite-based monoliths and coatings

- Project 5: High-temperature oxidation behaviour of ceramic coatings based on polymer-derived ceramic nanocomposites

- Project 6: Evolution of mechanical properties of coating systems during exposure at high temperature

- Project 7: High-temperature stability in harsh environments

- Project 8: Evaluation of additive manufacturing for RM-Si based substrates

- Project 9: Phase-field simulations of multiphase microstructural evolution in Mo-Si-based ternary alloy

- Project 10: Small-scale deformation and failure

- Project 11: Materials thermodynamics, kinetics and constitution in the Mo-Si-Ti-Cr-X system

- Project 12: Ab-initio calculations of bulk and interface properties at high temperatures

- Project 13: High temperature creep and fatigue of novel MatCom-ComMat systems (3rd period)

- Project 14: Elementary nanoscale mechanisms which govern nucleation, growth, oxidation and deformation processes in the high temperature Mo-Si-Ti system: Advanced in situ and ex situ TEM analysis

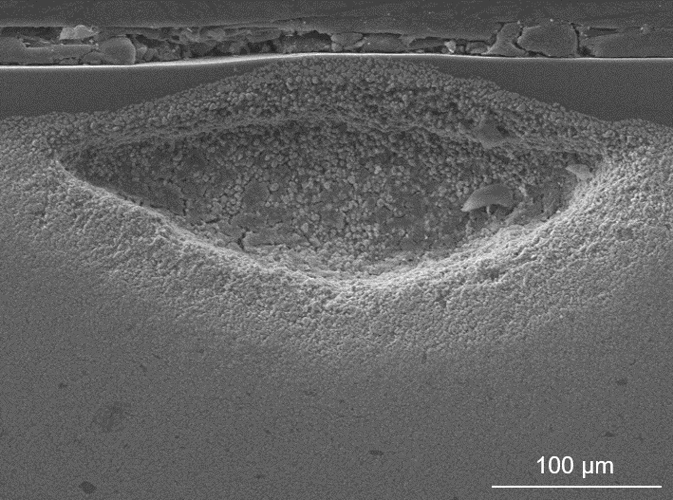

On May 7, 2025 Katharina Beck (DECHEMA Research Institute) successfully defended her dissertation entitled “Hot Corrosion and Oxidation Protection of Mo-based Refractory Metal Silicides” at the University of Bayreuth.

The research for her thesis, embedded in the framework of RTG 2561, focused on the oxidation and hot corrosion behavior of two novel Mo-Si-Ti alloys and the development of protective coatings. The use of these Mo-based refractory metal alloys could significantly increase the efficiency of turbine engines, as they enable higher combustion temperatures and have a significantly lower density when compared to conventional Ni-based alloys. In Mrs. Beck's work, the oxidation and hot gas corrosion mechanisms of the uncoated Mo-based alloys were clarified, two protective coatings were developed and the influences of the different coating elements were investigated.

After the successful Review of the Continuation Proposal in February DFG decided to extend RTG 2561 for its second funding period on May, 8th, 2024. The second funding period starts on October, 1st, 2024 and lasts until March, 31st, 2029. A budget of more than 4 Mio. Euro for this period was granted.

The scope of the RTG relates to the development, characterization and modelling of novel, revolutionary multi-phase composite systems capable of withstanding temperatures substantially beyond 1300°C and harsh environmental conditions as far as mechanical behaviour, environmental resistance and durability are concerned.

Still within the first funding period, RTG‘s second PhD cohort has already started in 2023 and RTG’s third PhD cohort will start in 2026. The doctoral students as well as all participating principal investigators from Karlsruher Institut für Technologie, Technische Universität Darmstadt and DECHEMA Forschungsinstitut Frankfurt are very grateful to the DFG for this funding and are happy to announce this success.

Press release by DFG

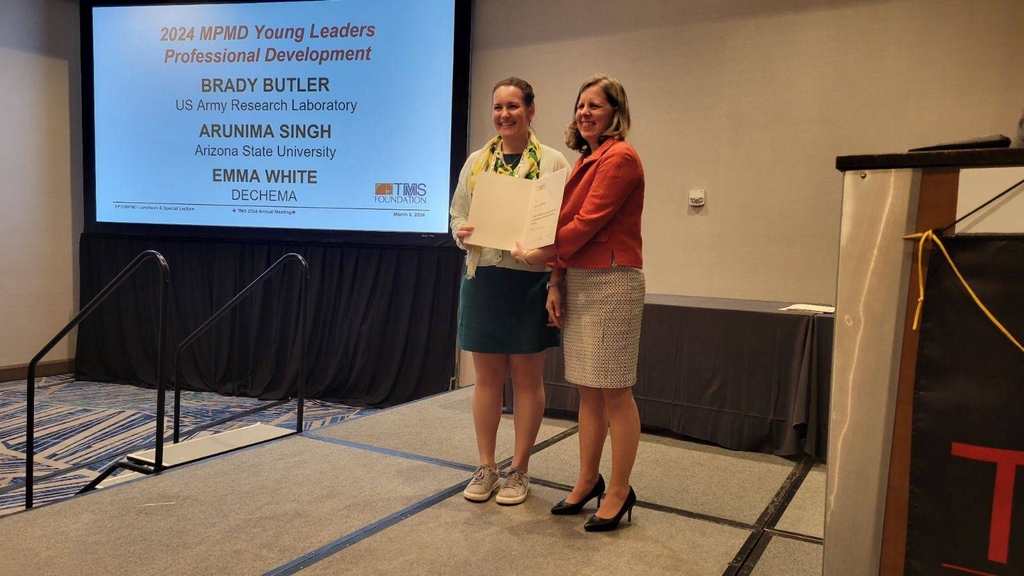

From 3-7 March 2024 more than 4,000 minerals, metals, and materials scientists and engineers convene at the TMS Annual Meeting & Exhibition in Orlando, USA, creating a major global forum for the exchange of ideas, presentation of research, and establishment of enduring connections within their professional community.

This year the DFI is contributing with seven co-authored talks and four talks presented by Lisa Koliotassis, Fabian Lanoy, Emma White and Mathias Galetz. Emma White is currently also head of the Powder Materials Committee and Mathias Galetz has been elected the JOM advisor for the Refractory Committee.

Emma White also received the Young Leader Professional Development Award, one of three awards presented at the event on 5 March 2024.

"It is a great honour to receive one of the TMS 2024 MPMD Young Leader Professional Development Awards. Since my first participation in 2011, I have received crucial foundational support from TMS as well as opportunities for scientific development as I started and built my professional career in materials science," comments Emma White. "TMS became the professional organisation where I felt at home and where I experienced many inspiring and informative exchanges at the forefront of materials science."

© DFI

Yangyiwei Yang successfully defended his PhD thesis with the title "Multiphysics-multiscale Simulation of Additive Manufactured Functional Materials". Congratulations from the RTG team!

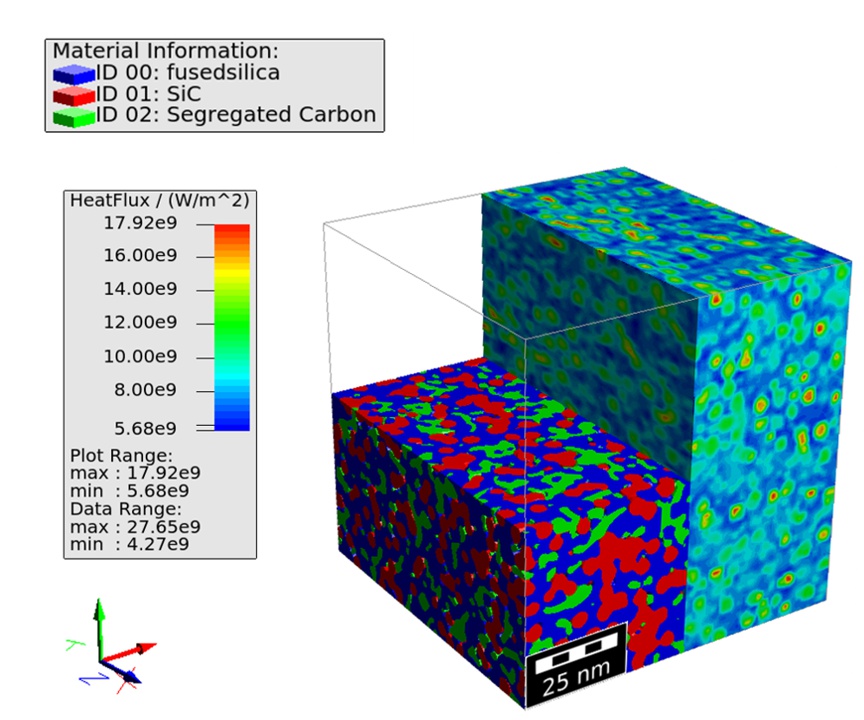

Among others, Mr. Yang developed successfully a diffuse-interface model to simulate anisotropic interphase thermal resistance and paved the theoretical and numerical foundation for the subproject P4. It enabled particularly finite element thermal homogenization calculation of polymer-derived nano-composites, thanks to the advantages of the diffuse-interface model, including quantitative nature and high flexibility in handling complex interphase topology. For instance, a series of thermal homogenization of nano- and microstructure reconstructed from TEM images could be carried out with varying interphase thermal resistance parameters. By comparing the calculated effective thermal conductivity of the nano-composites with experimental ones, the interphase thermal resistance and its temperature dependency can be inversely determined.

We congratulate Georg Winkens on the successful defense of his doctoral thesis. He was awarded the doctorate for his work on “Solid solution strengthening in single-phase Mo alloys”. In the framework of the RTG2561 funded by DFG, he contributed to improved understanding of the strengthening contributions by different dislocation types in refractory solid solutions.

He successfully implemented the recently developed models by Maresca and Curtin for the use within our research groups and the alloy development of the RTG. By the experimental synthesis of binary model alloys, he was able to test these modern models against others as well as to investigate the potential change of strengthening contributions by screw and edge dislocations depending on alloy composition:

https://doi.org/10.1038/s43246-023-00353-8

Apart from the Mo based solid solutions subject to the RTG, he contributed to the application of the respective models to refractory high entropy alloys from the Ta-Mo-Ti-Cr-Al system. These recent results were published in the RTG special issue in Advanced Engineering Materials:

https://doi.org/10.1002/adem.202301797

You may also see Georg's open access publications of research data and program codes on KIT's repository to improve the accessibility of our research results:

https://doi.org/10.35097/1784

https://doi.org/10.35097/1866

https://doi.org/10.35097/1786

https://doi.org/10.5445/IR/1000157208

https://doi.org/10.5445/IR/1000157205

We wish Georg all the best for his further career and look forward to discoveries in the field of physical metallurgy in the future.

Last Thursday and Friday (February, 1st and 2nd), the Deutsche Forschungsgemeinschaft and external reviewers were guest at KIT to assess the activities and the continuation proposal of RTG2561 “MatCom-ComMat: Materials Compounds from Composite Materials for Applications in Extreme Conditions”. The doctoral students and principal investigators from Karlsruher Institut für Technologie, Technische Universität Darmstadt and DECHEMA Forschungsinstitut presented their work in the form of presentations and posters as well as discussions with the review panel.

We thank Carolin König and Stefan Wagner for the preparation of the defense, our PhD students presenting their work in the form of talks, Nathalie Thor, Frauke Hinrichs, Mozhdeh Fathidoost, and Jurica Filipovic as well as all other contributors and eagerly wait for the final decision on May 8th.

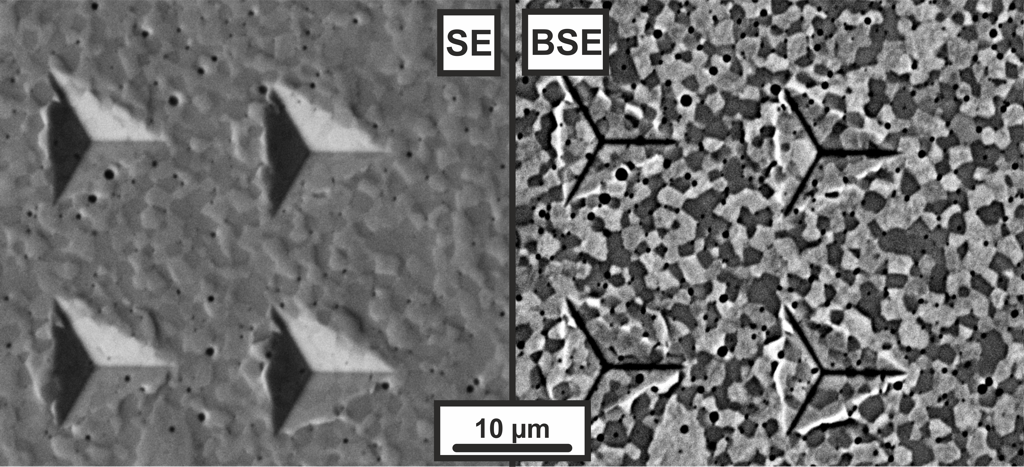

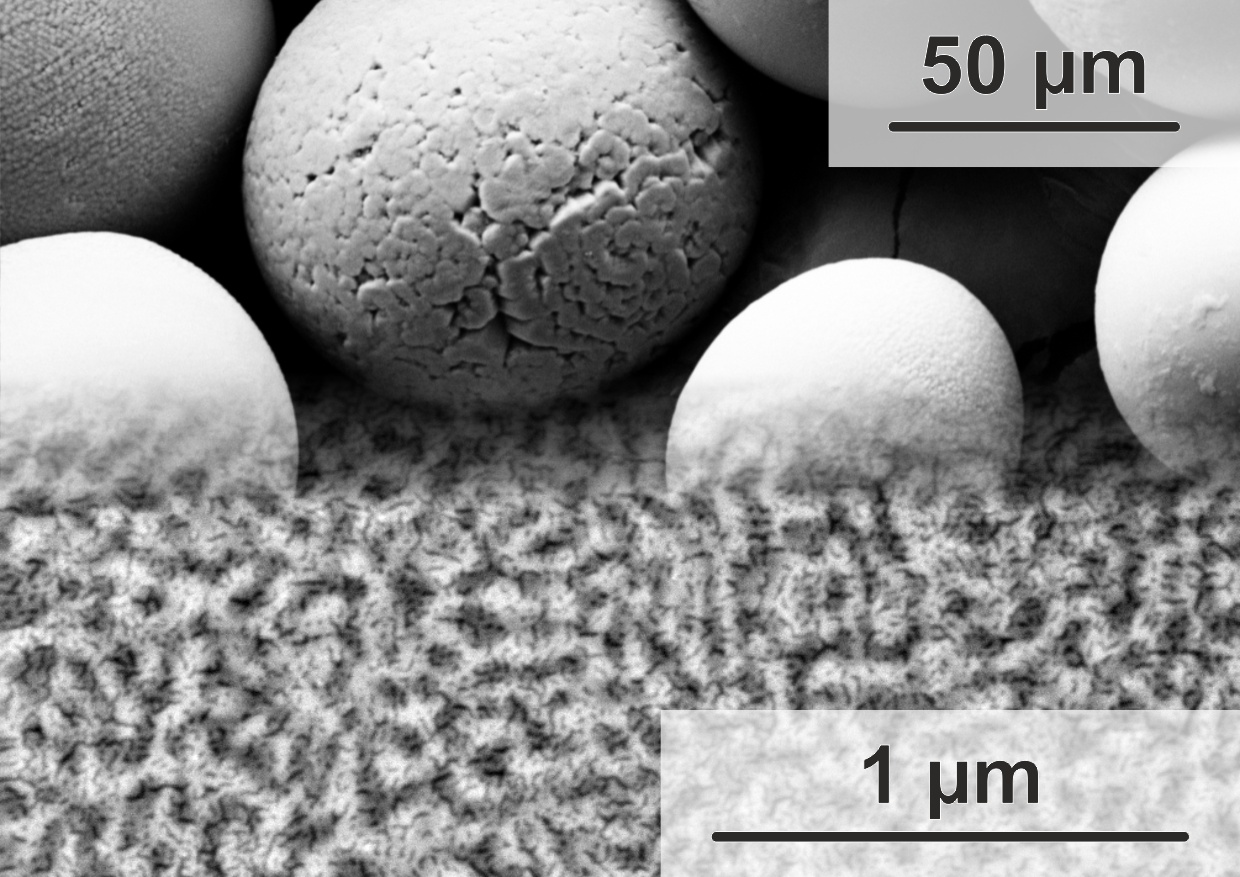

We congratulate Nathalie Thor for successfully defending her PhD thesis. She was awarded the doctorate for her thesis on “Process Optimization for Si(Hf,Ta)(B)(C,N) polymer-derived ceramics via microstructural analysis”.

In the framework of RTG2561, funded by DFG, she contributed to our work on the characterization of novel Si-based polymer-derived ceramics nanocomposites (PDC-NCs) for potential high temperature applications.

The major scope of her thesis work was to guide the process optimization of novel refractory metal-containing polymer-derived ceramics nanocomposites by a microstructural enhancement. She successfully unraveled the microstructure evolution of polysilazane and polycarbosilane-based PDC-NCs upon different heat treatments as well as sintering parameters and developed a comprehensive comparison between ceramic powders and bulk ceramics.

In the first period she successfully developed a sample preparation in order to analyze a novel as-pyrolyzed and heat-treated polysilazane-based ceramic via different electron microscopic methods, such as SEM and TEM. This ceramic was tailored on a molecular level with different molar ratios of Hafnium and Tantalum and underwent crystallization and phase separation. She was able to show in great detail that local decomposition in surface-near regions and the corresponding transition metal carbide particle coarsening is an active and characteristic mechanism upon high-temperature annealing in these material classes:

https://doi.org/10.1016/j.jeurceramsoc.2022.11.060

In the final period of her thesis, Nathalie focused on the detailed understanding of the microstructure development of a novel monolithic polycarbosilane-based PDC-NC with and without the addition of boron. The addition of boron brought further improvements in the desired tailoring of the microstructure in advanced novel Si-based bulk ceramics for high-temperature applications.

We wish Nathalie all the best for her further career and look forward to discoveries in the field of materials science and engineering in the future

Congratulations to Nils Petry from DECHEMA Forschungsinstitut on the successful completion of his PhD.

Within the framework of his thesis, Nils Petry has achieved a significant milestone with his work on the influence of polymer-derived ceramics, used as sintering aids for preparing ZrB2-based monoliths and their oxidation

https://doi.org/10.1111/jace.18473

His dedication and commitment have been instrumental in advancing our understanding of the impact of nitrogen and boron in such scales.

During the course of his research, Nils contributed to notable advancements in the characterization of ultra-high temperature ceramic nanocomposites (UHTC-NC) within the Si(HfxTa1−x)(C)N system, which was synthesized via the polymer-derived ceramics (PDC) synthesis route.

https://doi.org/10.1016/j.jeurceramsoc.2022.11.060

One abroad collaboration really stood out with the AHG in Krakow, Poland.

https://doi.org/10.1016/j.surfcoat.2023.130049

This collaborative approach has demonstrated, that PDC be used to successfully enhance the oxidation resistance of refractory high temperature alloys.

Nils Petry's achievements underscore his commitment to excellence in the RTG. We extend our best wishes to him as he continues his career in the ceramic industry. Congratulations once again on this well-deserved accomplishment!

We congratulate Frauke Hinrichs on successfully defending her doctoral thesis. She was awarded the doctorate for her thesis on “Microstructure and Oxidation Resistance of single-phase and multi-phase Cr-Mo-Si Alloys”. In the framework of the RTG2561 funded by DFG, she contributed to our work on the development of refractory element based alloys for potential high temperature application.

She implemented for the first time the powder synthesis of high Mo containing alloys on lab by ultrasonic atomization and presented the successful industrial upscale in collaboration with industry:

https://doi.org/10.3390/met11111723

The major scope of her thesis work was the transfer of the alloy principle of pesting resistant Mo-Si-Ti to Cr containing Mo-Si alloys. She successfully transferred the alloy design to a novel alloy from the ternary Cr-Mo-Si system, incl. similar volume fractions of solid solution and silicide:

https://doi.org/10.1016/j.corsci.2022.110566

This alloy turned out being resistant against the catastrophic oxidation of most high Mo alloys (pesting) but also resistant against problems characteristic of Cr based alloys like nitridation.

In the final period of her thesis, Frauke focused on the oxidation resistance and mechanical properties of monolithic solid solutions derived from her previous investigations. These refractory solid solutions do not only exhibit an outstanding oxidation resistance but also significant ductility:

https://doi.org/10.5445/IR/1000166092

We wish Frauke all the best for her further career and look forward to discoveries in the field of materials science and engineering in the future.

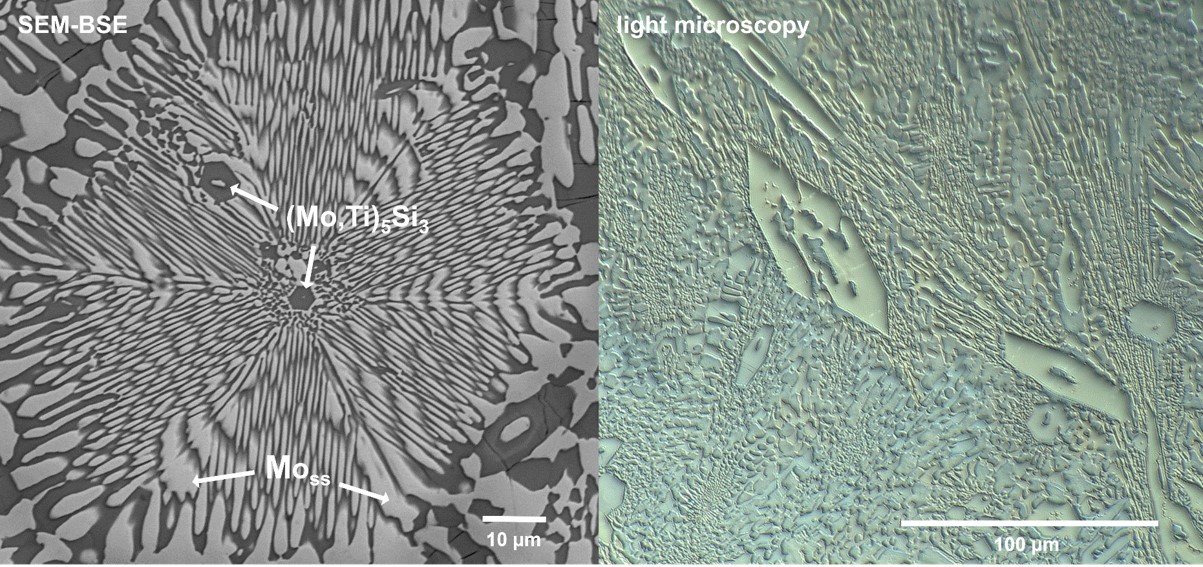

Yuhan Cai successfully defended his PhD thesis with the title "Phasenfeldmodellierung der mikrostrukturellen Entwicklung in Mehrkomponenten-Legierungssystemen". Congratulations from the RTG team!

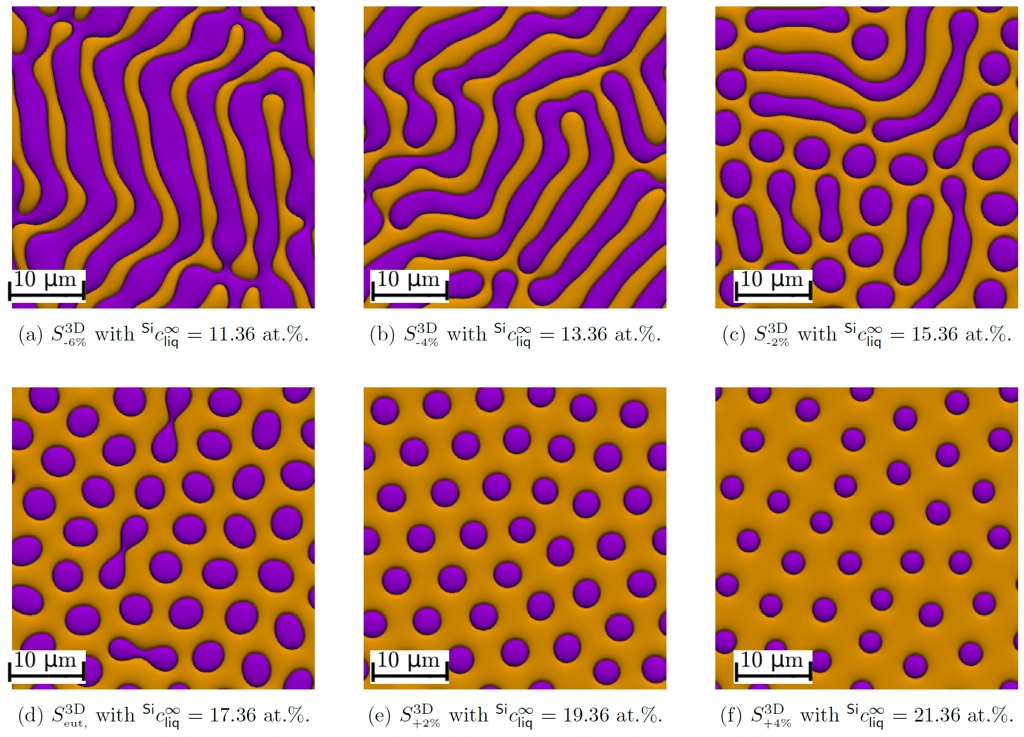

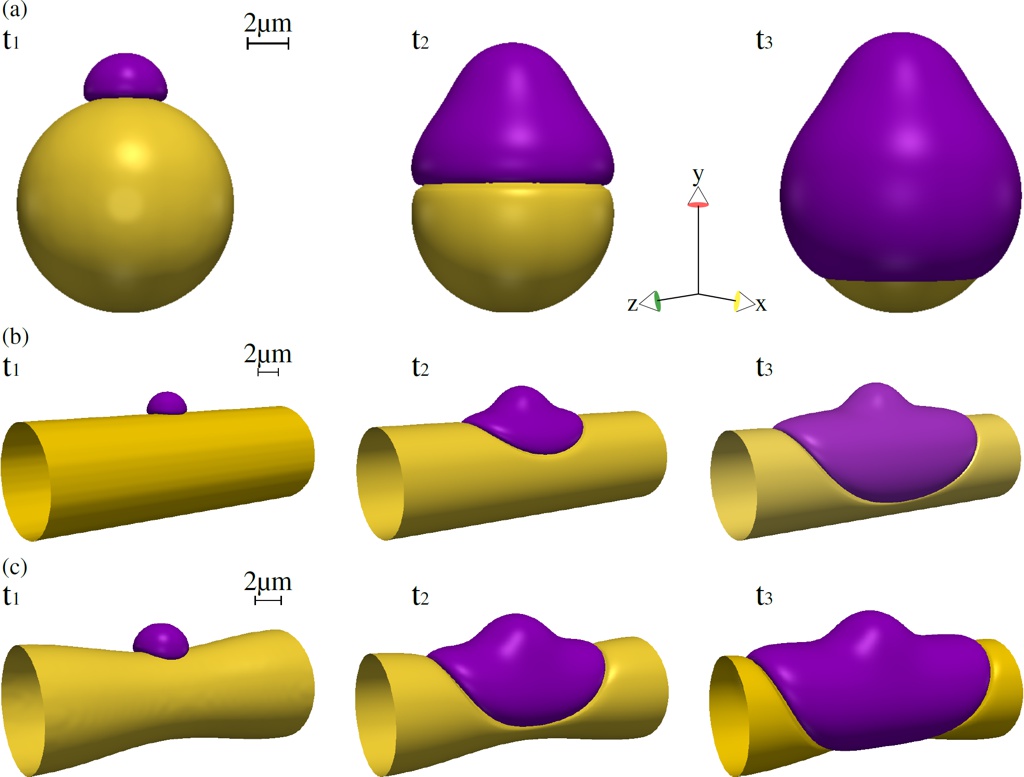

By simulating the lamellae growth during a eutectic transformation in Mo-Si-Ti alloy, Yuhan and the collaborators have constructed a microstructure selection map, which will be helpful to the RTG in the development of new tailored materials by new designing the microstructural morphology. His computational investigation of the quasi-peritectic four-phase reaction, combined with insights from the previous studies on the peritectic transition in binary systems, provides additional understanding of the underlying growth mechanism for the formation of lamellae pairs in the Mo-Si-Ti alloy. The study on the bending growth of lamellae explains two possible reasons for this phenomenon as found in experiments.

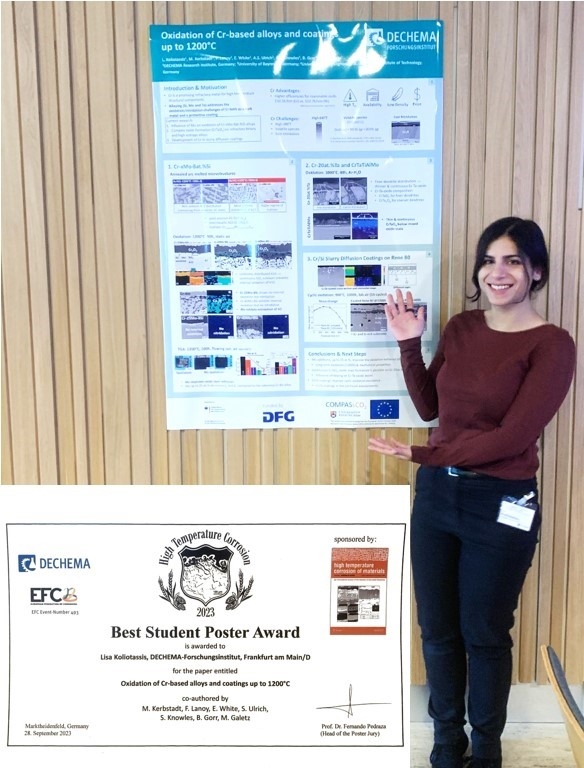

The picturesque town of Marktheidenfeld, nestled along the banks of the Main River in Germany, provided a platform for knowledge exchange and collaboration among experts at the High Temperature Corrosion and Oxidation 2023 Workshop from September 25th to 29th, 2023.

This international event brought together 100 of the world’s leading scientists, researchers, and industry experts from thirteen countries to discuss the critical topic of high temperature corrosion and oxidation. The workshop was held against the backdrop of pressing challenges in energy production, particularly in the context of shifting from fossil fuels to renewable and carbon-neutral processes. The different talks highlighted the necessity of developing innovative material solutions capable of withstanding the harsh environments associated with renewable energy processes and pushing the efficiencies, and thus process parameters, at elevated temperatures.

Discussions centered on the impact of novel process conditions and media, such as nitride, carbonate or chloride salt melts, supercritical CO2, and changing the compositions of process gases. A key topic was higher levels of hydrogen (H2) and water vapor (H2O) when moving towards a hydrogen based economy. Many discussions covered the impact of new additive manufacturing techniques on the microstructure, chemistry and finally the oxidation and corrosion resistance of parts for high temperature components. Nine members of the RTG took part and had the opportunity to discuss their research projects and potential exchanges with top international scientist such as the Prof. Beth Opila (Virginia), Prof. Brian Gleeson (Pittsburgh) and Prof. Shigenari Hayashi (Hokkaido).

The workshop developed key takeaways and formed future directions also for the high temperature corrosion and oxidation research within the RTG. The event underscored the critical role of materials science and engineering in addressing the pressing challenges associated with the transition to renewable energy sources. Collaborative efforts, international partnerships, and multidisciplinary research approaches are essential components of future progress. As the workshop came to a close, it left all attendees from the RTG inspired and motivated to continue their pursuit of materials solutions that will shape the energy landscape of the future. RTG member Lisa Koliotassis was awarded the poster price for the best poster.

| Name | Institute | |||

|---|---|---|---|---|

| Dr. | White, Emma | DECHEMA-Forschungsinstitut (DFI) | ||

| PD | Galetz, Mathias | DECHEMA-Forschungsinstitut (DFI) | ||

| PD Dr. | Ionescu, Emanuel | Department of Materials and Earth Sciences (TUD) | ||

| Prof. | Pundt, Astrid | Institute for Applied Materials (KIT) | ||

| Prof. | Xu, Bai-Xiang | Department of Materials and Earth Sciences (TUD) | ||

| Prof. | Nestler, Britta | Institute for Applied Materials (KIT) | ||

| Prof. | Gorr, Bronislava | Institute for Applied Materials (KIT) | ||

| Prof. | Albe, Karsten | Co-Spokesperson | Department of Materials and Earth Sciences (TUD) | |

| Prof. | Heilmaier, Martin | Spokesperson | Institute for Applied Materials (KIT) | |

| Prof. | Oechsner, Matthias | Staatliche Materialprüfungsanstalt Darmstadt (TUD) | ||

| Prof. | Riedel, Ralf | Department of Materials and Earth Sciences (TUD) | ||

| Prof. | Schwaiger, Ruth | Institut für Energie- und Klimaforschung (former KIT, now FZJ) | ||

| Prof. | Eggeler, Yolita | Laboratory for Electron Microscopy (KIT) |

| Name | Project | Institute | ||

|---|---|---|---|---|

| M.Sc. | Bernauer, Jan | P1, doctoral researcher (1st cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Boroojerdi, Minoo | P1, doctoral researcher (2nd cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Kredel, Samuel Aeneas | P2, doctoral researcher (1st cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Camacho Ramirez, Anggie Daniela | P2, doctoral researcher (2nd cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Thor, Nathalie | P3, doctoral researcher (1st cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Nurak, Ingrit Sisilia Rosari | P3, doctoral researcher (2nd cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Yang, Yangyiwei | P4, doctoral researcher (1st cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Fathidoost, Mozhdeh | P4, doctoral researcher (2nd cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Petry, Nils-Christian | P5, doctoral researcher (1st cohort) | DECHEMA-Forschungsinstitut (DFI) | |

| M.Sc. | Prill, Büsra | P5, doctoral researcher (2nd cohort) | DECHEMA-Forschungsinstitut (DFI) | |

| M.Sc. | Filipovic, Jurica | P6, doctoral researcher (1st cohort) | Staatliche Materialprüfungsanstalt Darmstadt (TUD) | |

| Dr. | Kontermann, Christian | P6, assoc. PostDoc | Staatliche Materialprüfungsanstalt Darmstadt (TUD) | |

| M.Sc. | Beck, Katharina | P7, doctoral researcher (1st cohort) | DECHEMA-Forschungsinstitut (DFI) | |

| M.Sc. | Korell, Lukas | P7, doctoral researcher (2nd cohort) | DECHEMA-Forschungsinstitut (DFI) | |

| M.Sc. | Hinrichs, Frauke | P8, doctoral researcher (1st cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Falcão, Gabriely | P8, doctoral researcher (2nd cohort) | Institute for Applied Materials (KIT) | |

| Dr. | Schliephake, Daniel | P8, assoc. PostDoc | Institute for Applied Materials (KIT) | |

| M.Sc. | Cai, Yuhan | P9, doctoral researcher (1st cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Nourani Niaki, Kimiya | P9, doctoral researcher (2nd cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Winkens, Georg | P10, doctoral researcher (1st cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Ramdoss, Sri Rathinamani | P10, doctoral researcher (2nd cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Czerny, Andreas | P11, doctoral researcher (1st cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Ramasamy Chitra, Arun | P11, doctoral researcher (2nd cohort) | Institute for Applied Materials (KIT) | |

| M.Sc. | Hammoud, Julie | P12, doctoral researcher (2nd cohort) | Department of Materials and Earth Sciences (TUD) | |

| M.Sc. | Thota, Hemanth | P14, doctoral researcher (1st cohort) | Laboratory for Electron Microscopy (KIT) |