ProFeAl – Process development for commercial and efficient turbine components made from iron-aluminides

Motivation

FeAl intermetallics show a great potential for applications in challenging components

- Great oxidation and corrosion resistance in different mediums (vapor, salty atmosphere)

- Promising mechanical properties, such as specific Young’s modulus, specific strength, high tribological resistance

- 60 – 80 % density of commercial steels und superalloys

- Cost-efficient main components of Fe and Al

Objective

- Evaluation of different alloys based on demand profile

- Evaluation of casting, forging & additive manufacturing and the interaction between manufacturing, microstructure and material properties

Methods

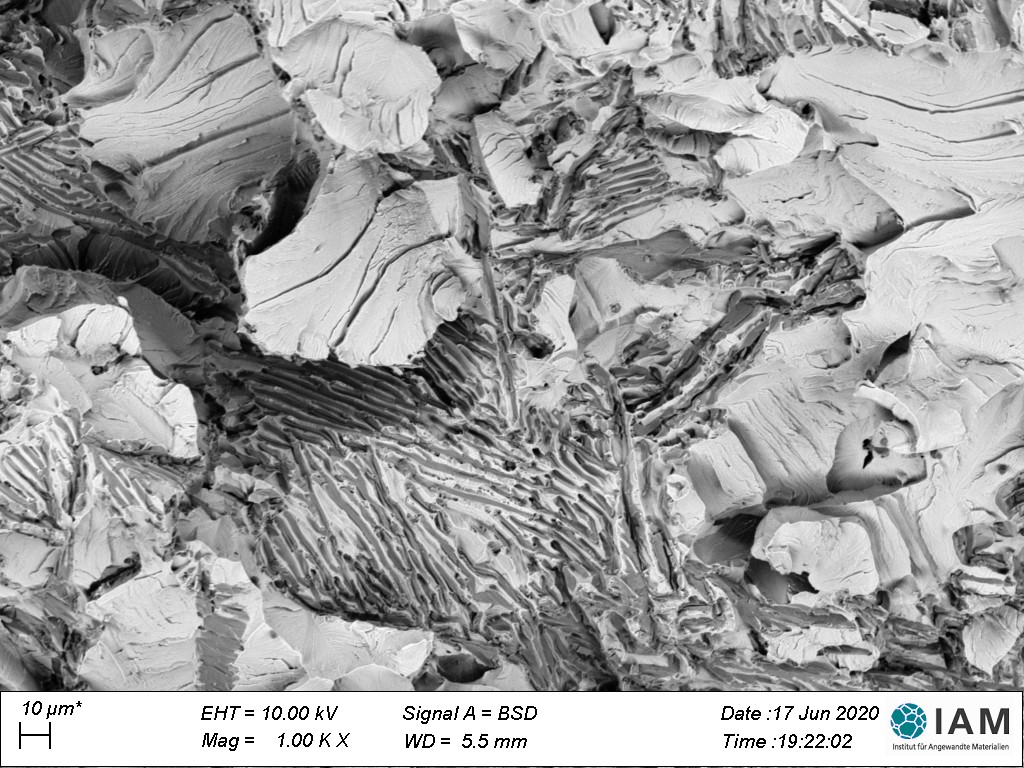

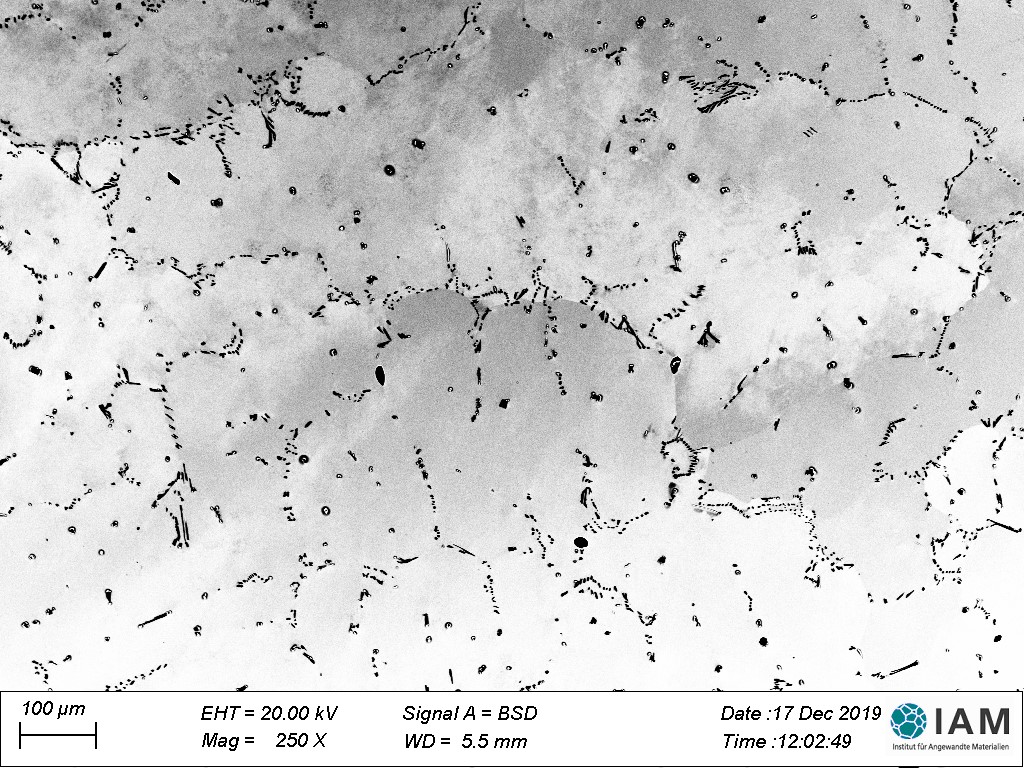

- Microstructure analysis

- Quasistatic experiments and LCF & HCF tests at temperature range from room temperature to 700°C

- Evaluation of fracture surfaces

Project partners

- Siemens AG

- Rolls-Royce Deutschland Ltd & Co KG

- Max-Planck-Institut für Eisenforschung GmbH

- Access e.V.

- Otto Junker GmbH

- Leistritz AG