Competence

Composing the future of composites ...

Hybrid materials, i.e. composites, made or joint from several materials play a very important role in industrial application. The aim of hybrid lightweight construction is the mass reduction of lightweight structures and simultaneously the increase of performance of the construction, which is reflected in higher strength, stiffness or improved fatigue strength. In addition to steels with a comparably high stiffness and density both light metals like aluminium and magnesium as well as polymers feature a high potential for lightweight construction due to their low density. One major advantage of the last-mentioned material class is furthermore the excellent processability. A disadvantage of all lightmetals and polymers is the low stiffness which may be increased by reinforcements like ceramic or metallic fibres or particles increasing both absolute and specific stifness. The combination of different materials in compounds or composites results in the evolution of an interface which is essential for the composite's performance as it provides the internal load transfer between the composite's components.

Future materials

The relevance of hybrid materials and lightweight structures in industry has increased during the last years. The BMW hybrid structure concept featuring an aluminium front end joint with a steel structure and the use of composites in aircraft industry are prominent examples. The use of composites is also evident in aircraft construction, as exemplified by the Airbus A380: In addition to "GLARE", a composite consisting of aluminum sheets and glass fibre-reinforced plastics, pure fibre-reinforced plastics are used in the area of the tail unit. The high potential can be illustrated in the aviation sector. Not long ago, composites accounted just 10% of the total mass of the Boeing 777, for the design of the Airbus A380 it is already 20%. In the case of the Boeing 787 and the Airbus A350XWB it increased up to 50%. Here, fir the first time complete fuselage sections are made of composites.

More than just a combination

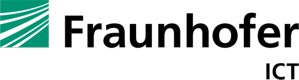

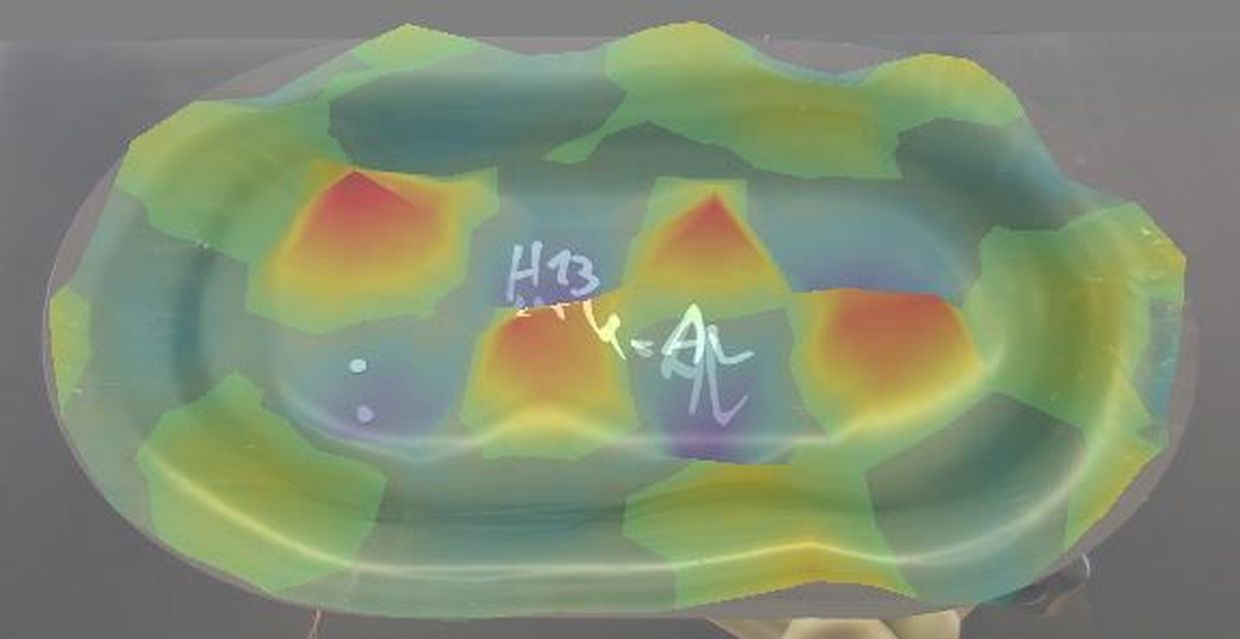

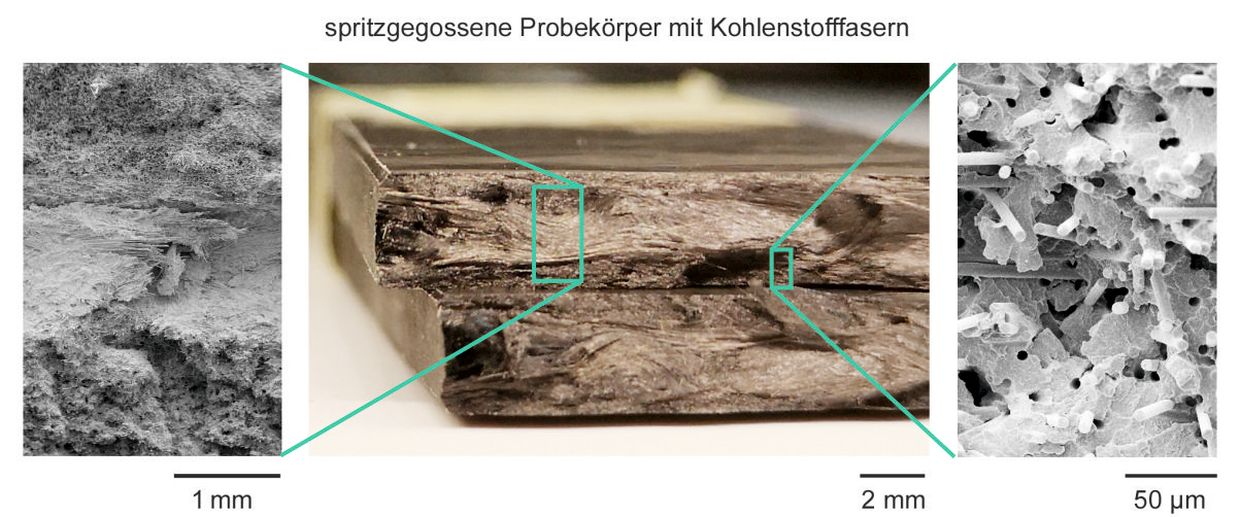

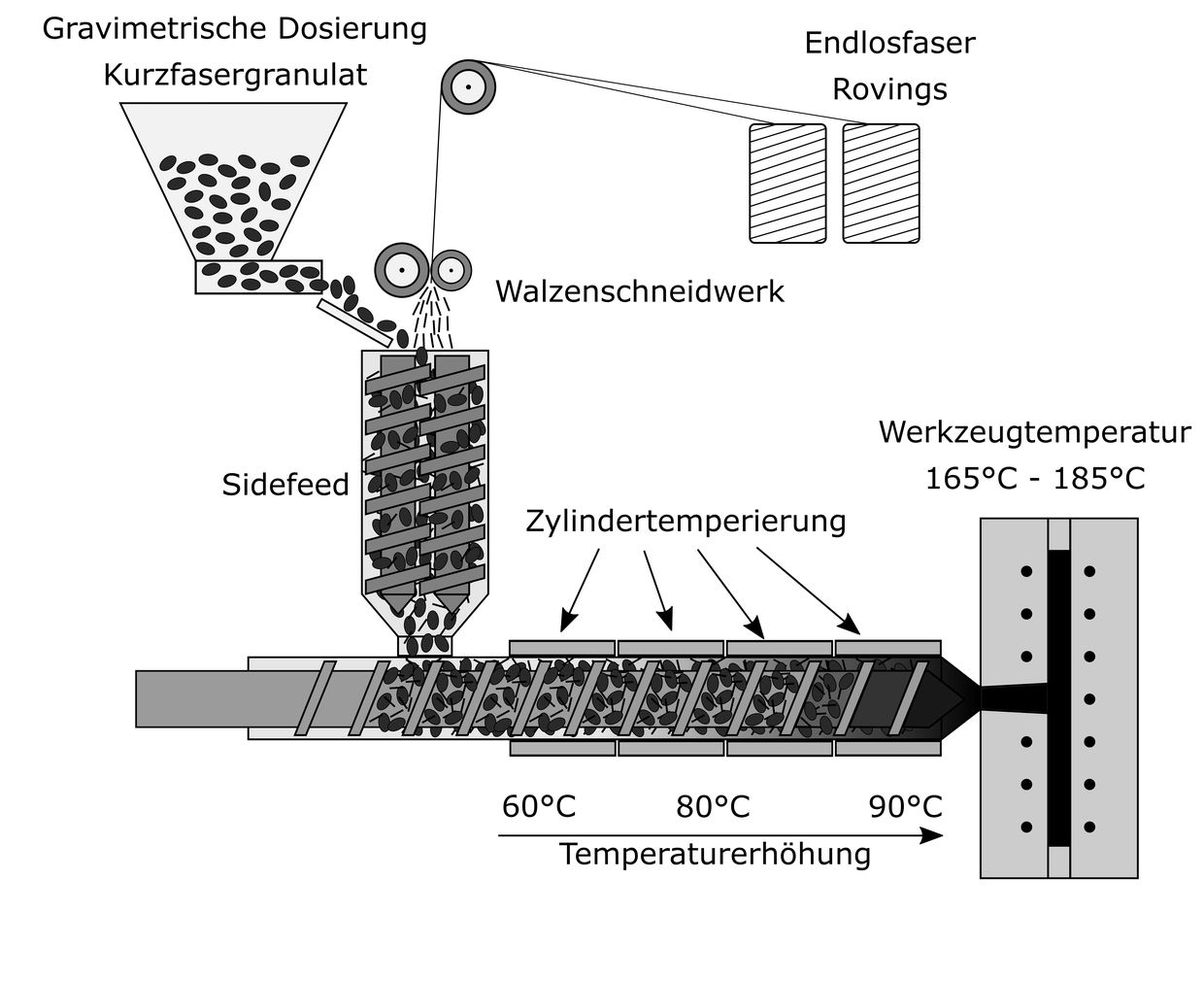

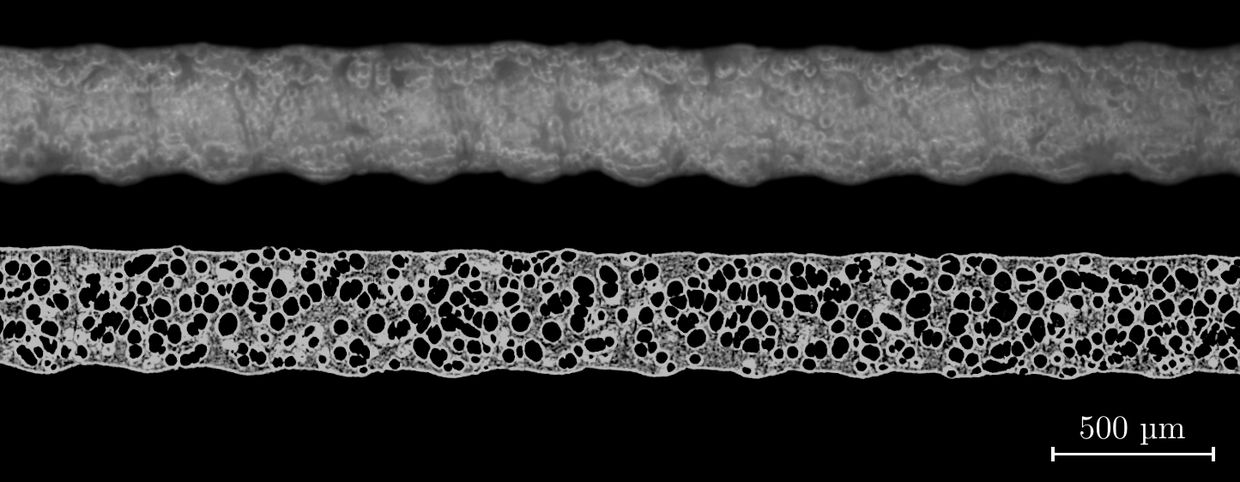

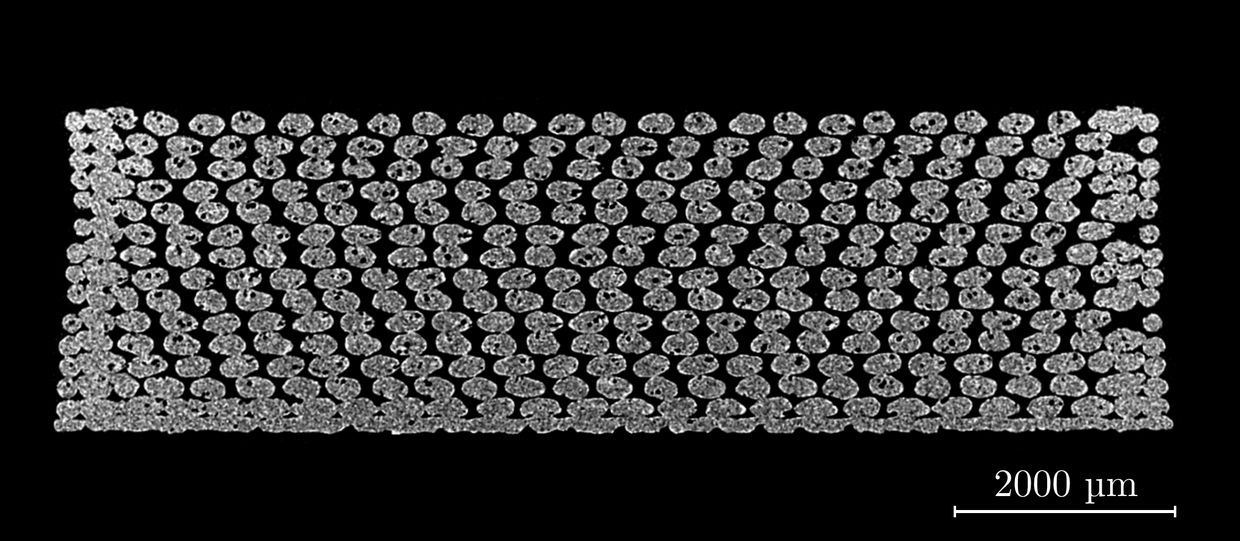

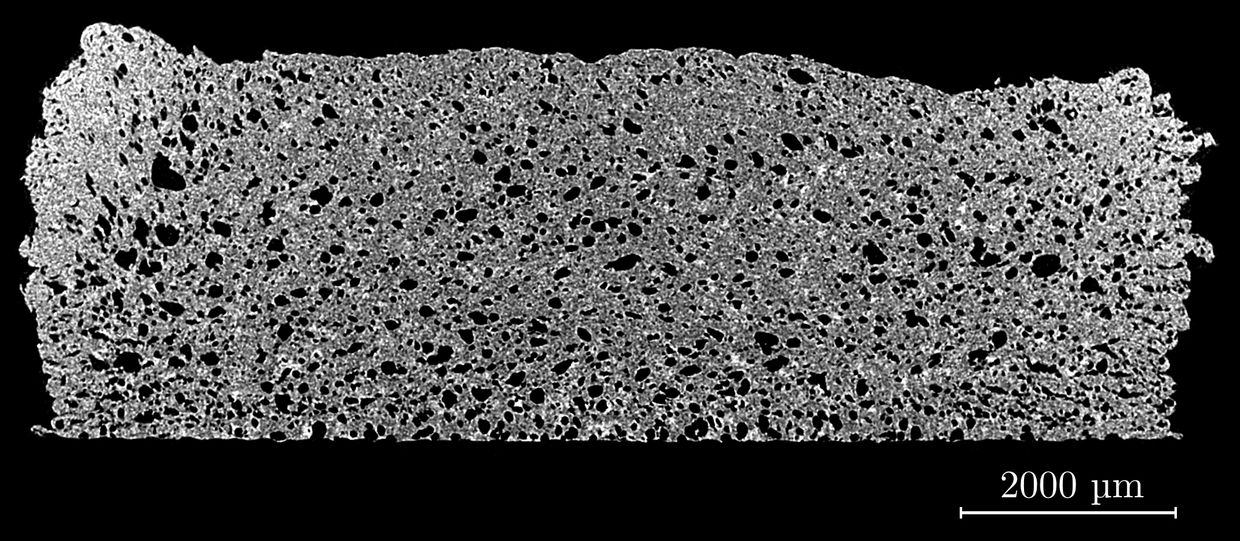

The development of modern tailored composites depends on basic knowledge of their composition, their structure, their synthesis and their processing for each component. This previous history of a materials influences the microstructure, the interface evolution and potential microstructure defects. In addition, the type of components, their volume fraction, their spatial arrangement and their affinity to each other are also determining factors for the composites. These facts suggest the physical properties of a composite material. Vice versa, it is possible to tailor the mechanical properties of composites.

Core comptence of the group is the deduction of correlations between processing, microstructure and properties for composites. For that purpose, their microstructure is characterised using metallography and microscopy. The microstructure is correlated with mechanical properties obtained from different mechanical testing procedures. From these results theoretical material models can be derived which allow for the optimisation of the material design as well as for a prediction of component's properties.

Cooperations

Our activities are coordinated with the Division Lightweight Technology of the KIT Institute of Vehicle Systems Technology (FAST) and the Division Polymer Engineering of the Fraunhofer Institute for Chemical Technology (ICT).