3D Atome Probe Tomography

Group Leader

Group Members

Dr.-Ing. Julia Rau

M.Sc. Johannes Wild (joint member with Defects in Materials)

M.Sc. Moritz Ludwig

Delphine Chassaing

Marina Weinhard

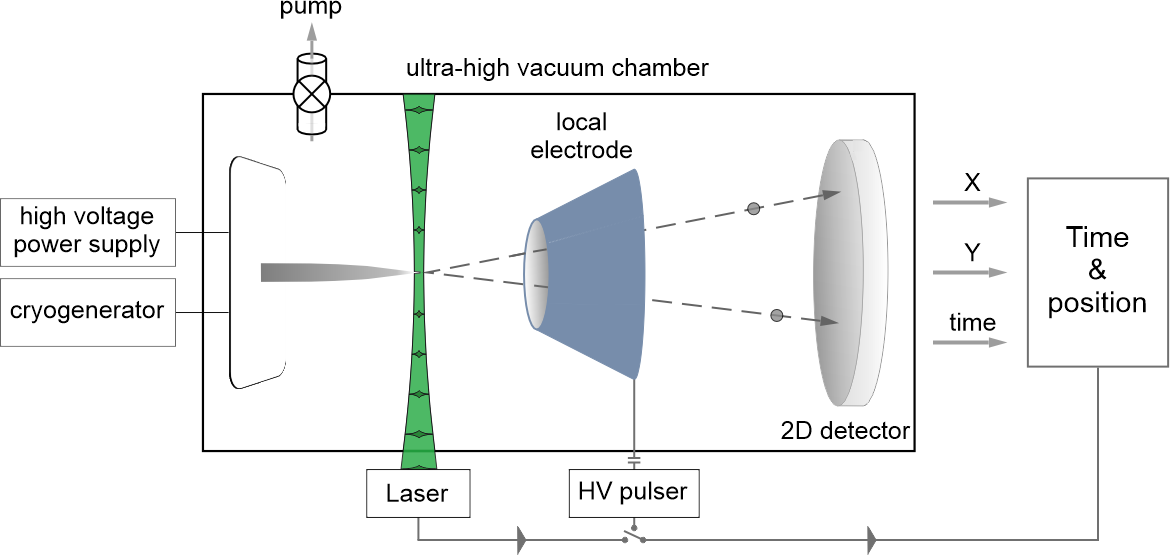

Atom Probe Tomography (APT) is the only material characterization technique that allows for both 3D imaging and chemical composition analysis at a sub-nanometer scale. Applying a high DC voltage to a needle specimen with an apex diameter of less than 100 nm generates an electrostatic field almost high enough to evaporate surface atoms. Using laser or voltage pulsing, the atoms are evaporated and ionized in a controlled manner, which then are projected onto a 2D detector. This time-resolved and position-sensitive detector reveals the identity of the evaporated ions by time-of-flight mass spectroscopy. To decrease the lateral movement of tip atoms, the tip is kept at cryogenic temperatures. With the 3D information of the detected ions and the arrival sequence, the specimen can be reconstructed with near-atomic resolution.

Equipment

Local Electrode Atom Probe (LEAP 4000X HR)

- UV-laser or voltage pulsing

- Reflectron for enhanced mass resolution

Limitations and Constraints

- Sample require a SEM compatible sample size for FIB preparation or electropolishing

- Organic materials are challenging and can only be accepted in special cases

- The sample will be prepared as a sharp needle with a diameter of 20 nm to 300 nm

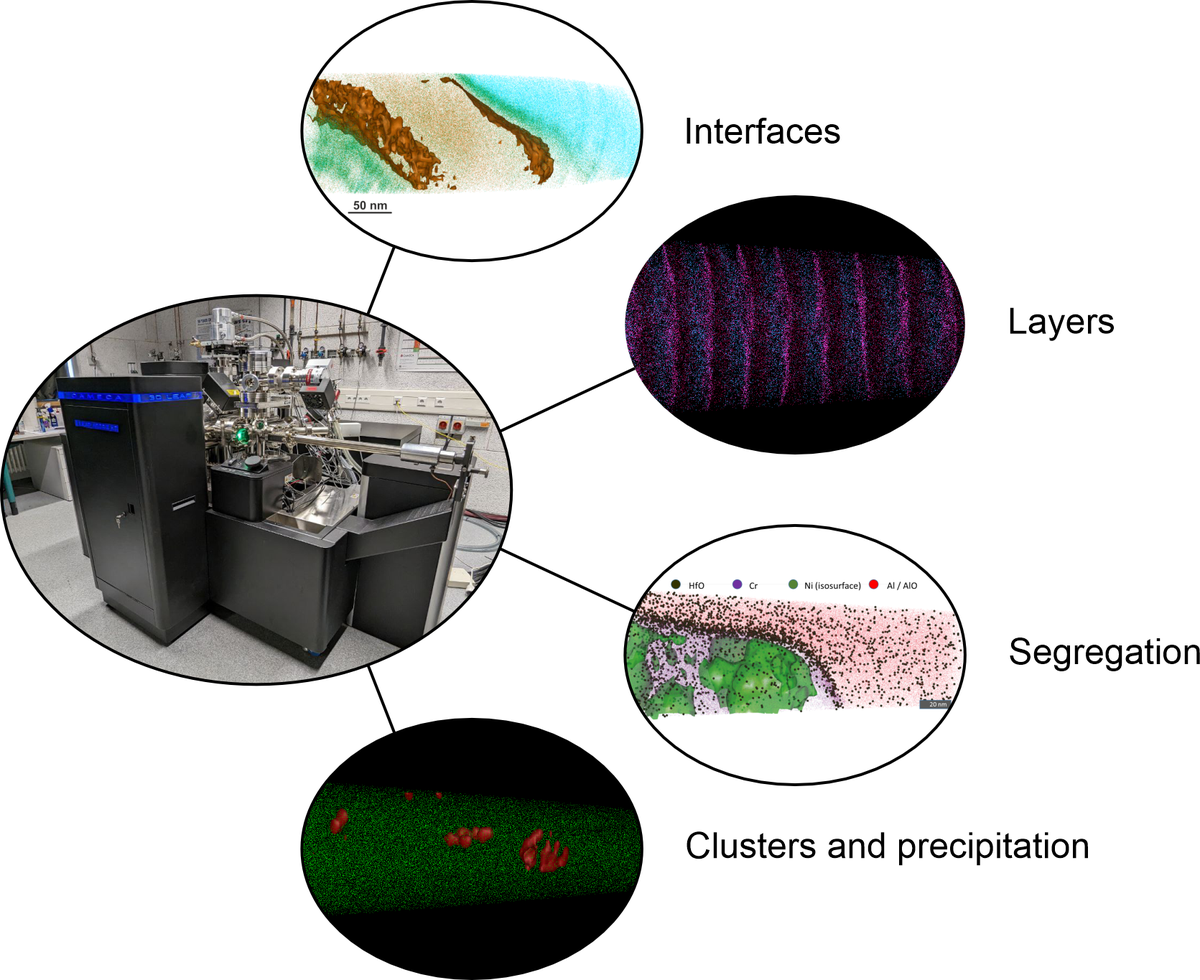

Projects

At KNMFi, a wide variety of research topics is covered. These include:

- materials for extreme environments such as high temperature applications

- structural and functional ceramics

- thin films

- hydrogen storage and battery materials

- fundamental investigations like strengthening mechanisms, precipitation processes, and phase transformations

Collaboration

APT instrument time can be requested through the Karlsruhe Nano Micro Facility Karlsruhe Nano Micro Facility (KNMFi).