Mechanical Testing

Heads

Dr.-Ing. Stefan Guth, Dr.-Ing. Stefan Dietrich, Dr.-Ing. Wilfried Liebig

Testing Equipment

- 6 Electromechanical Universal Testing machines with maximum loads between 2.5 kN and 500 kN (tension, compression, torsion and bending)

- 14 Cyclic bending machines "weBi"

- Hardness testers for all testing techniques

- 1 Impact testing machine (300 J)

- 9 Servohydraulic Testing machines for isothermal fatigue test with maximum loads between 10 and 400 kN

- 1 Servohydraulic Testing machine for superimposed cyclic tension/torsion load (250 kN / 4kNm)

- 1 Servohydraulic Testing system (2-specimens-test-bench) for complex thermo-mechanical fatigue testing (100 kN)

- 1 Servohydraulic Testing machine for test frequencies up to 1000 Hz (maximum load: 35 kN) for the superimposition of low- and high-cycle fatigue loads

- 4 Linear motor driven Testing machines for isothermal and thermo-mechanical fatigue tests (3 - 12 kN)

- 3 Resonance testing machines (maximum loads at 63, 100 and 250 kN)

- 6 Electromechanical torsion machines for torsional loads between 10 and 50 Nm

- 3 Micro Universal testing machines for maximum loads between 20 and 100 N

- 2 Test benches for superimposed fretting fatigue tests

- 1 linear motor testing machine for cyclic tests under salt fog conditions with heating and exhaust system (Fmax = 7 kN)

Tempering Devices

- Refridgerators (T > -196 °C)

- Resistive heating devices (200° C < T < 1050 °C)

- Radiation heating devices (100 °C < T < 1600 °C)

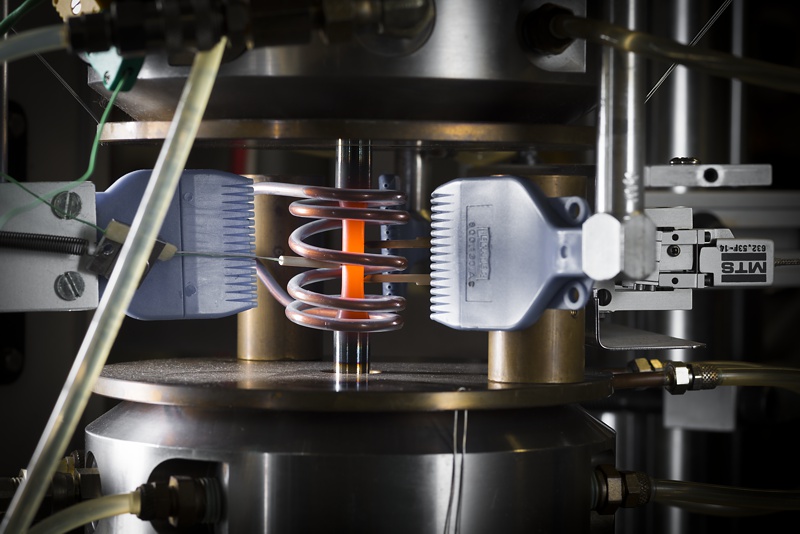

- Inductive heating (20 °C < T < 1200 °C)

Special Equipment

- Acoustic emission analysis

- Heating-cooling device for the realisation for temperature gradients

- DC-Potentiometers (high-temperature use)

- Light Microscope for in situ observation during mechanical testing

- Indenters for registrating hardness tests