EU-Project: Lightweight steel Leaf Springs with improved durability and reliability – LEAFSLIM

N.N.

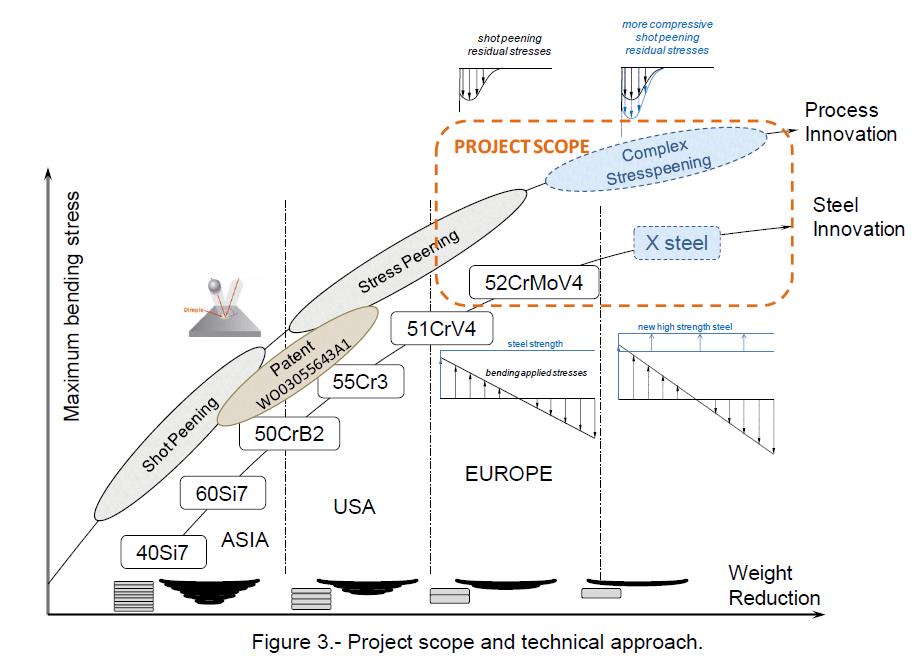

This project is carried out in cooperation with several industrial partners and another research institution. The aim of the project is to improve the fatigue behavior of leaf springs in heavy truck applications. As a result, the springs can be built lighter and vehicle weight can be reduced. To achieve this goal, new steel grades with increased basic strengths are being developed. On the other hand, modified shot peening treatments are being applied, in which peening is carried out under preload and at elevated temperatures (stress peening and warm stress peening). In addition to the experimental characterization of the surface layer properties and the fatigue behaviour, finite element simulations of the modified peening processes are carried out in order to be able to predict the surface layer conditions without expensive parameter studies.

Motivation

In the course of striving for lightweight construction, leaf springs in the commercial vehicle sector are always shot peened, for which special procedures under preload (stress peening) are used. In order to be able to exploit further lightweight construction potential ("downsizing"), improved processes and further approaches to increasing the fatigue strength of springs are necessary. Both improved steel grades and optimized shot peening processes (e.g. warm stress peening) can be developed. In the LEAFSLIM project these two approaches are pursued.

Goal

- Weight reduction by means of improved steel grades and improved shot peening processes

Methods

- Exp. testing of shot peening strategies (warm / under preload) for optimization of the surface layer condition

- Fatigue testing

- Finite-element simulation of modified shot peening strategies