SPP 2183: Multi-variable close-loop control with feedforward control of forming product properties - Fundamentals and application to punch-hole-rolling

M.Sc. Fabian Mühl

Motivation

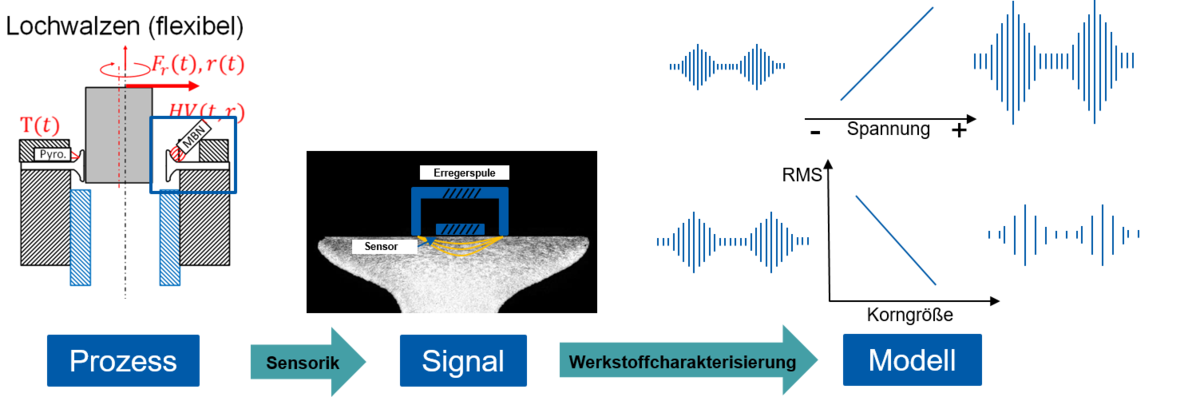

In this project the effect of the magnetic Barkhausen noise (MBN) is used for the inline control of product properties in the innovative forming process of punch-hole rolling. As the material properties can only be determined indirectly by MBN analysis, a calibration of the MBN signal has to be performed. For this purpose, flat steel samples (DC04) have to be characterized with a MBN system. In addition, the specimen states with respect to grain size, hardness, roughness and residual stresses have to be characterized quantitatively. By comparing the determined material properties with the MBN signal, the material-specific calibration functions can be set up, so that quantitative predictions can be made about microstructure and hardness with the help of a MBN analysis.

Goal

- Inline control of product properties in the innovative forming process of punch-hole rolling.

Untersuchungen

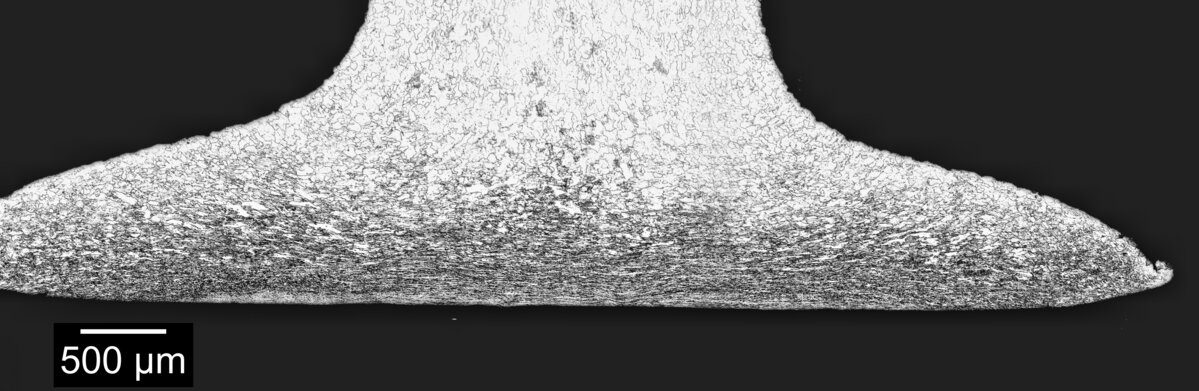

- Modeling and simulation oft he punch-hole rolling to predict geometry, grainsize and hardness

- Characterization of the maufactured component states (microstructure, hardness, residual stress critical)

- Characterization of the manufactured component states by MBN