Project 8: Evaluation of additive manufacturing for RM-Si(-B-X) based substrates

Dr. Frauke Hinrichs (1st cohort)

Dr. Frauke Hinrichs (1st cohort)

M.Sc. Gabriely Falcão (2nd cohort)

Supervisors: Prof. Martin Heilmaier, Prof. Astrid Pundt

Support by assoc. members: Dr. Daniel Schliephake

In this project, the Mo-Si-based and Cr-Si-based alloys have been investigated as potential, novel high-temperature materials based on specific properties that exceed the limits of current state-of-the-art alloys. Mo-Si-based alloys are investigated due to their high solidus temperatures which are fundamental to improved high-temperature strength and creep resistance. In contrast to Mo-Si alloys Cr-Si alloys often form slow-growing scales up to ≈ 1000 °C, consisting of a protective layer of Cr2O3.

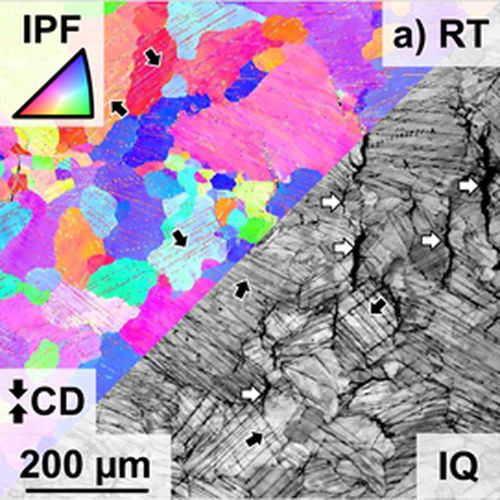

During the first funding period it has been found that in an as-cast condition Cr-Mo-Si alloys can in fact exhibit oxidation resistance up to 1100 °C and ductility even at room temperature. Plastic deformation of sincle phase Cr-Mo-Si solid solution alloys was found to be guided by twin formation from room temperature up to 900 °C. Further investigations in this alloy system are carried out on a homogenized condition to improve the desired properties and to investigate the fundamental principles that lead to the outstanding properties of Cr-Mo-Si solid solution alloys.

The second cohort of project no. 8 attempts to answer the following questions:

- How do Cr and Ti, affect the Mo-Si system in terms of the oxide layers formation and oxidation properties?

- What is the mechanical behavior, in terms of, ductility and deformation mechanisms, for these alloys in a homogeneous microstructure compared to dendritic microstructure?

- What significant influence does Si have in the oxidation resistance of Cr-Mo-Si solid solution alloys?

- What are the solubility limits of Mo and Si contents that ensure resistance against pesting, nitridation, and oxidation, while maintaining ductility at room and high temperatures?

[1] F. Hinrichs, et al., Preprint on doi:10.5445/IR/1000166092.

[2] S. Obert, et al., Metals, 2021, 11 (1), 169.

[3] F. Hinrichs, et al., Corrosion Science, 2022, 207, 110566.

[4] A. S. Tirunilai, Advance Engineering Materials, 2022, 24 (11), 2200918.

[6] S. Obert, et al., J. Mater. Res. Technol., 2020, 9 (4), 8556–8567.

[7] S. Obert, et al., Acta Materialia, 2020, 184, 132.

[8] A. S. Dorcheh, et al., Corrosion Science, 2018, 130, 261–269.