DFG Project T-TRIP: Investigation of transformation induced plasticity during precipitation formation in quenched and tempered steels and maraging steels

Motivation

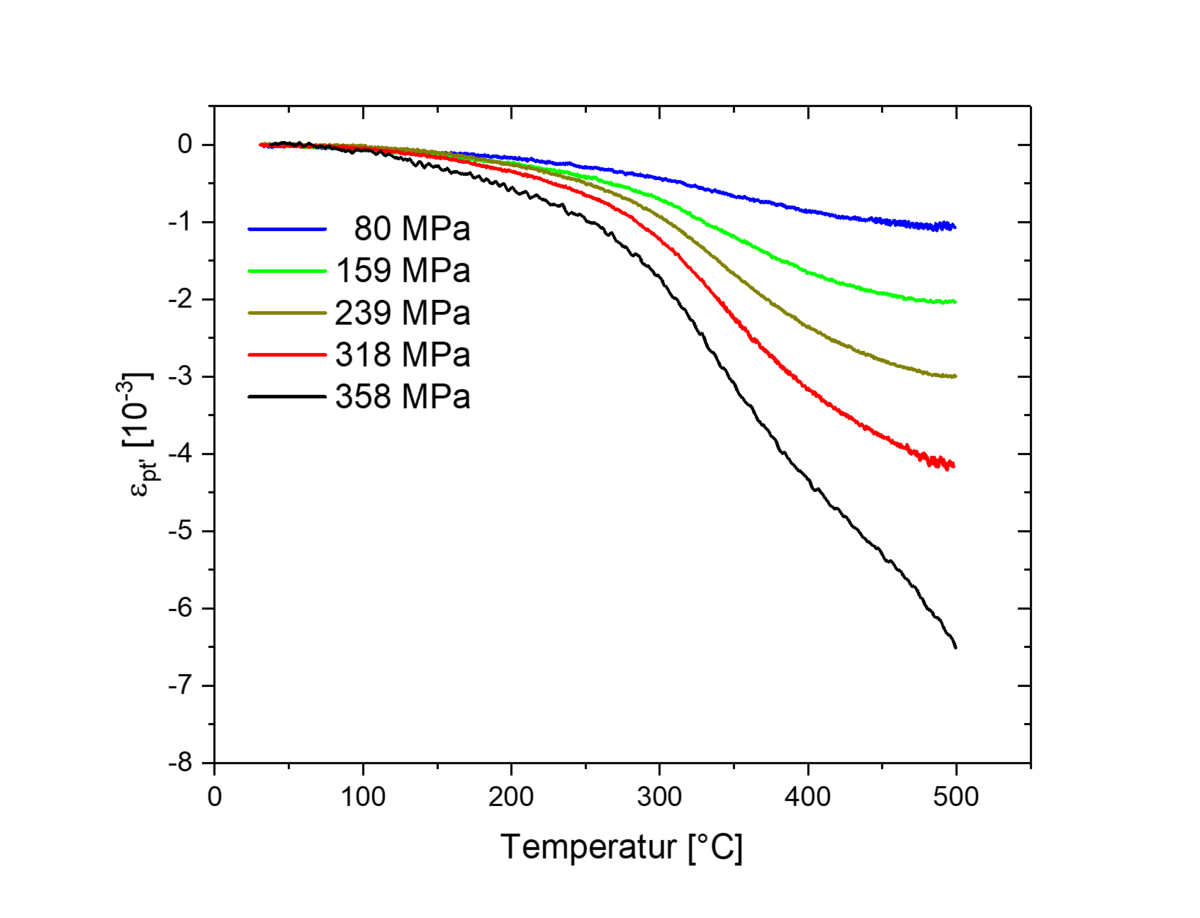

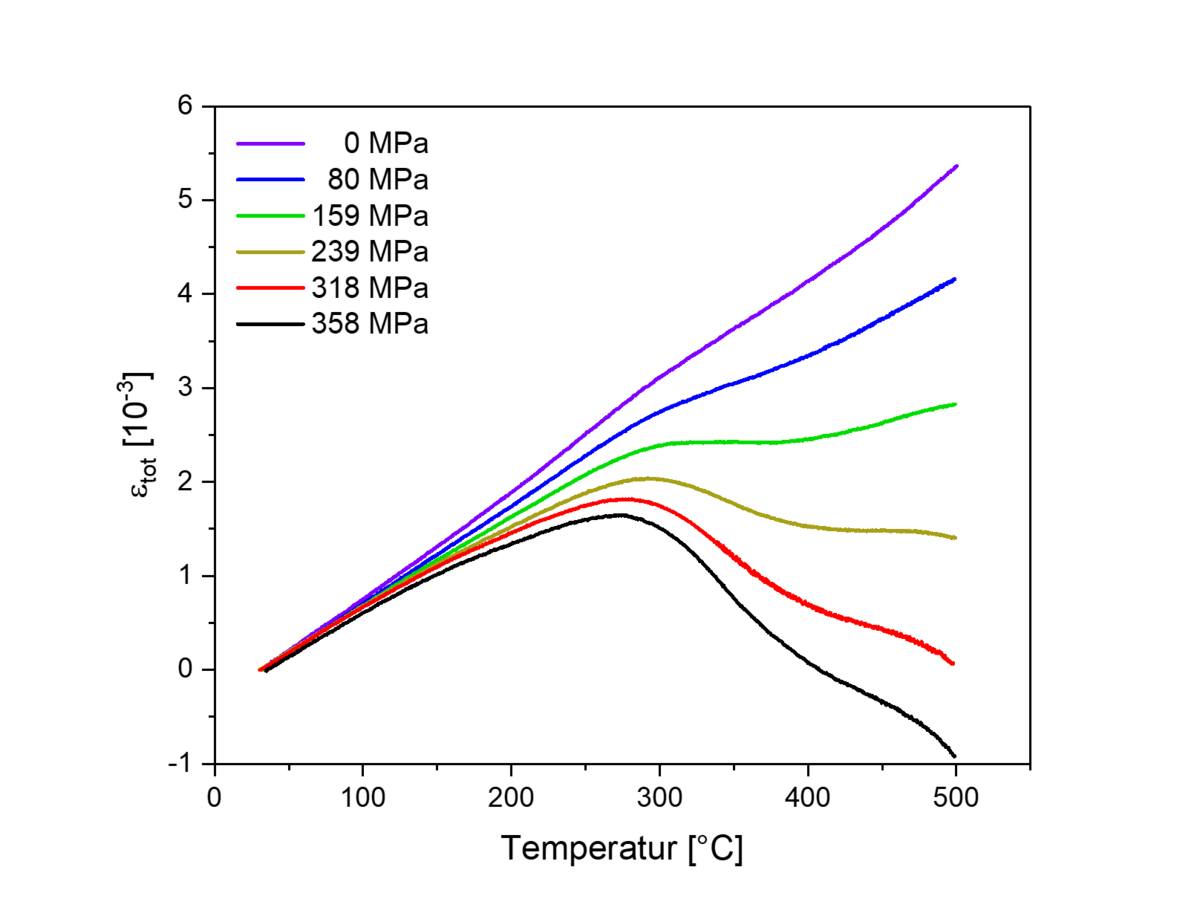

Transformation induced plasticity is the anisotropic, permanent deformation caused by a phase transformation under stress. It influences the component distortion and the residual stress state after heat treatment, which are decisive target values in many manufacturing technologies in order to ensure the usability of the component. The existing research on the influence of stress on precipitation reactions in steels show a considerable gap in the state of knowledge about the microstructural mechanisms and correlations of the transformation induced plastic deformation. Therefore the simulation and prediction of microstructural and stress states after tempering heat treatment plays an important role, especially for manufacturing processes where (residual)stresses are present during the precipitation formation (e.g. tempering or laser-based additive manufacturing).

Goals

The primary objective of the present project is to determine the dominant mechanisms of transformation induced plasticity during the formation of precipitates in tempering and maraging steels. On this basis, a descriptive kinetic model is to be developed, which should enable the mechanisms to be used by adjusting the influencing factors in a purposeful manner in the future. As a result, the following objectives are defined:

- Investigation of the strain change due to the transformation induced plasticity as a function of the applied stress for different precipitation reactions.

- Determination of the relationship between the transformation induced plastic strain and the progress of phase transformation for individual precipitation reactions and its link to each microstructural state resulting from the selection of steel.

- Description and evaluation of the microstructural influencing parameters such as dislocation densities, carbide sizes and distributions as well as the influence of the matrix hardness on the phase transformation kinetics and the related transformation induced plasticity .

By providing a better understanding of the transformation plastic induced effect and its material and load-specific dependencies as well as mathematical modelling, the basis for process optimisation of tempering regarding material selection and process controlling via FEM simulations including proper experiments is created.

Investigations

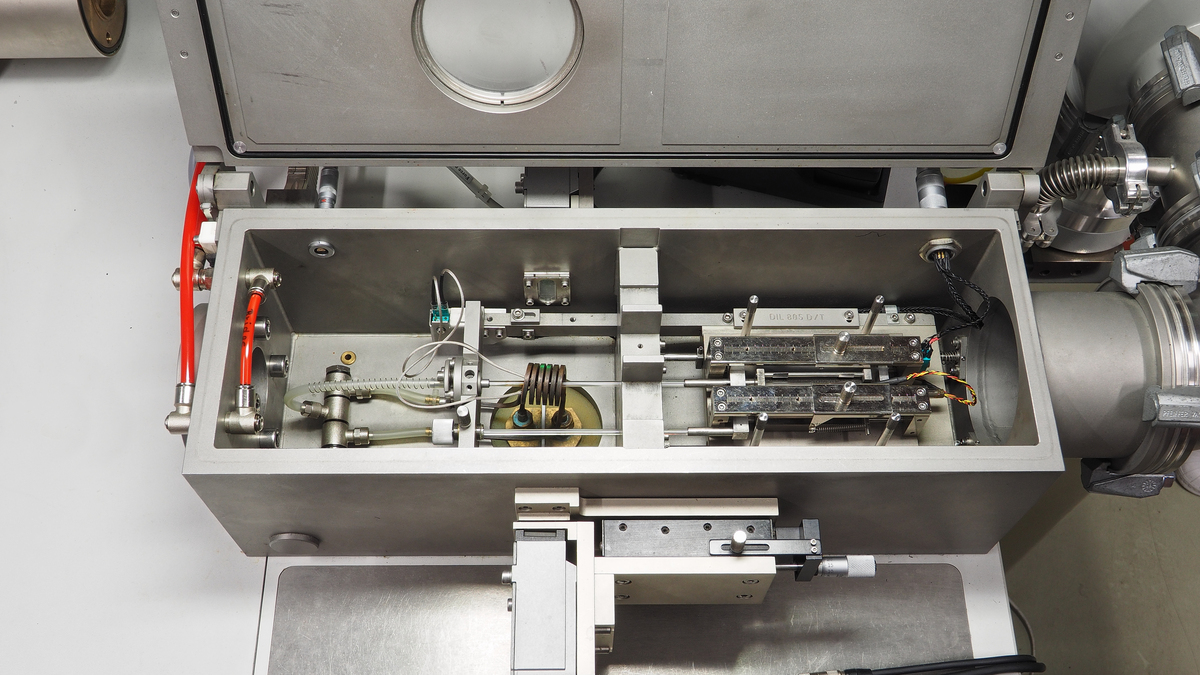

- Dilatometric investigation of the transformation induced plasticity during precipitation formation in quenched and tempered steels and maraging steels under variation of the influencing parameters.

- Mechanical characterisation (e.g. hardness and compression limit) of tempered steels, as well as microstructural characterisation using SEM/TEM images and radiographic analysis.

- Simulation of precipitation development and transformation induced plasticity during tempering in order to verify the TRIP models and characterize the dependencies under microstructural properties.