Powder injection molding (PIM)

In the injection molding of feedstocks, i.e. organic binders highly filled with metal or ceramic powders (Powder Injection Molding, PIM), the components are debound after the injection molding process and finally sintered into metal (Metal Injection Molding, MIM) or ceramic parts (Ceramic Injection Molding, CIM).

Materials

| Ceramics: Al2O3, ZrO2, ZrO2-Al2O3, Al2O3/TIN (electrically conducting ceramics), under development Si3N4 |

| Metals: Carbonyl-Fe, 316L (1.4404), 17-4PH (1.4542), Cu, under development WC-Co, Tungsten and tungsten alloys |

With powder injection molding, a process has become established in macroscopic molding technology that allows the high cost-effectiveness of injection molding series production to be used for the manufacture of metal or ceramic products. For this purpose, further process steps are being implemented in the process sequence. For example, the so-called feedstocks are used for powder injection molding. These mixtures, which are prepared as homogenously as possible, contain 50-60 vol.% powder in an organic binder. The latter usually consists of a low-molecular wax component, a thermoplastic and additives mainly for homogeneous distribution of the powder particles in the organic matrix. Otherwise the binder is used exclusively for molding (=> green compact) and must be removed after injection molding (=> brown compact). This debinding step can be performed thermally, pyrolytically, catalytically, by dissolution or combinations thereof. The parts can then be sintered to approx. 95-99 % of the theoretical density. The sintering atmosphere is either high vacuum, hydrogen or nitrogen or a mixture of both gases. When the carbon content in a steel has to be adjusted, hydrogen/methane mixtures will be used.

The high porosity of the brown stock leads - depending on the powder content in the feedstock - to a linear sinter shrinkage of the parts in the range of 15-23 %. This must be compensated for by an appropriate oversizing of the injection mold.

Achievable tolerances

The tolerances currently achievable with micro powder injection molding are ± 0.5 % of the nominal dimension. Through thorough process optimization, values of ± 0.3 % to ± 0.1 % (in special cases) can also be achieved.

|

left:

Green compact immediately after demolding from the injection mold |

17-4PH

|

right: |

| Powder injection molding of steel dispenser housings 17-4PH |

|

|

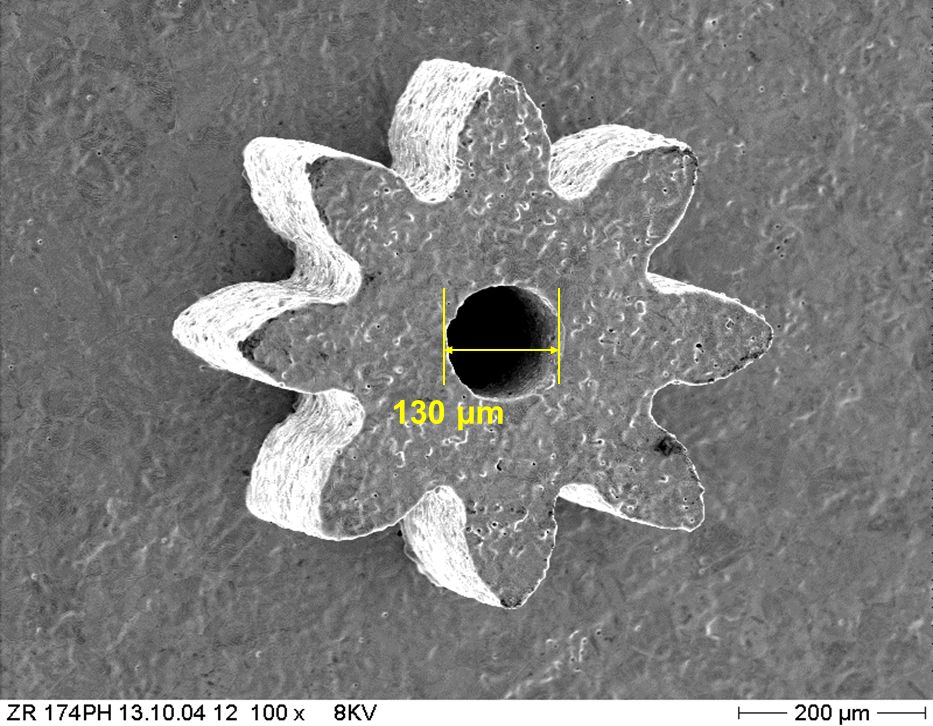

| Turbine plate, injection molded from ZrO2 |

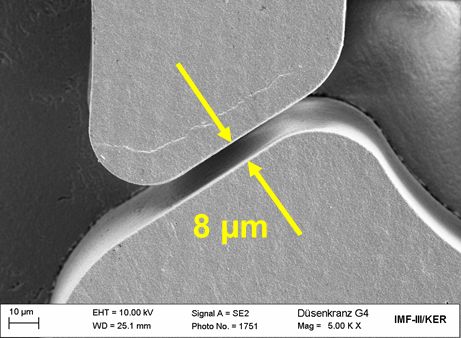

Micro-gear wheel in steel 17-4PH, Outer diameter = 610µm |

|

|

|

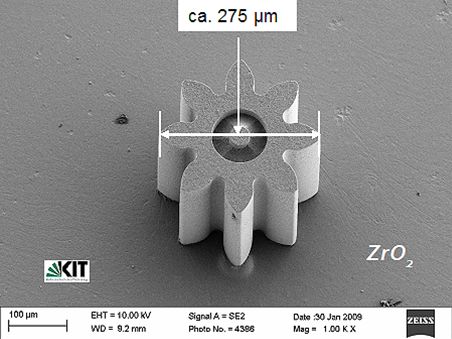

The world''s smallest CIM gear wheel: ZrO2, Outside diameter approx. 275µm |